© Siemens AG 2011

Monitoring and diagnostics

for industrial PCs

SIMATIC IPCs are rugged industrial PCs for professional au- tomation solutions in

The SIMATIC IPC DiagMonitor monitoring and signaling soft- ware recognizes possible hardware and software faults at an early point in time, and provides corresponding messages for the Maintenance Station. In connection with several SIMATIC IPCs, client/server network architectures can be set up via LAN and can centrally monitor all SIMATIC IPCs in plant facilities using DiagMonitor. The integrated webserver lets you view and manage data via an internet browser. Efficient service structures can be established by integrating automated com- munication paths, e.g. by means of Ethernet,

DiagMonitor supplements the operating data of the monito- red PCs with text messages, transmits them via the SNMP OPC server and outputs them in the associated asset management view.

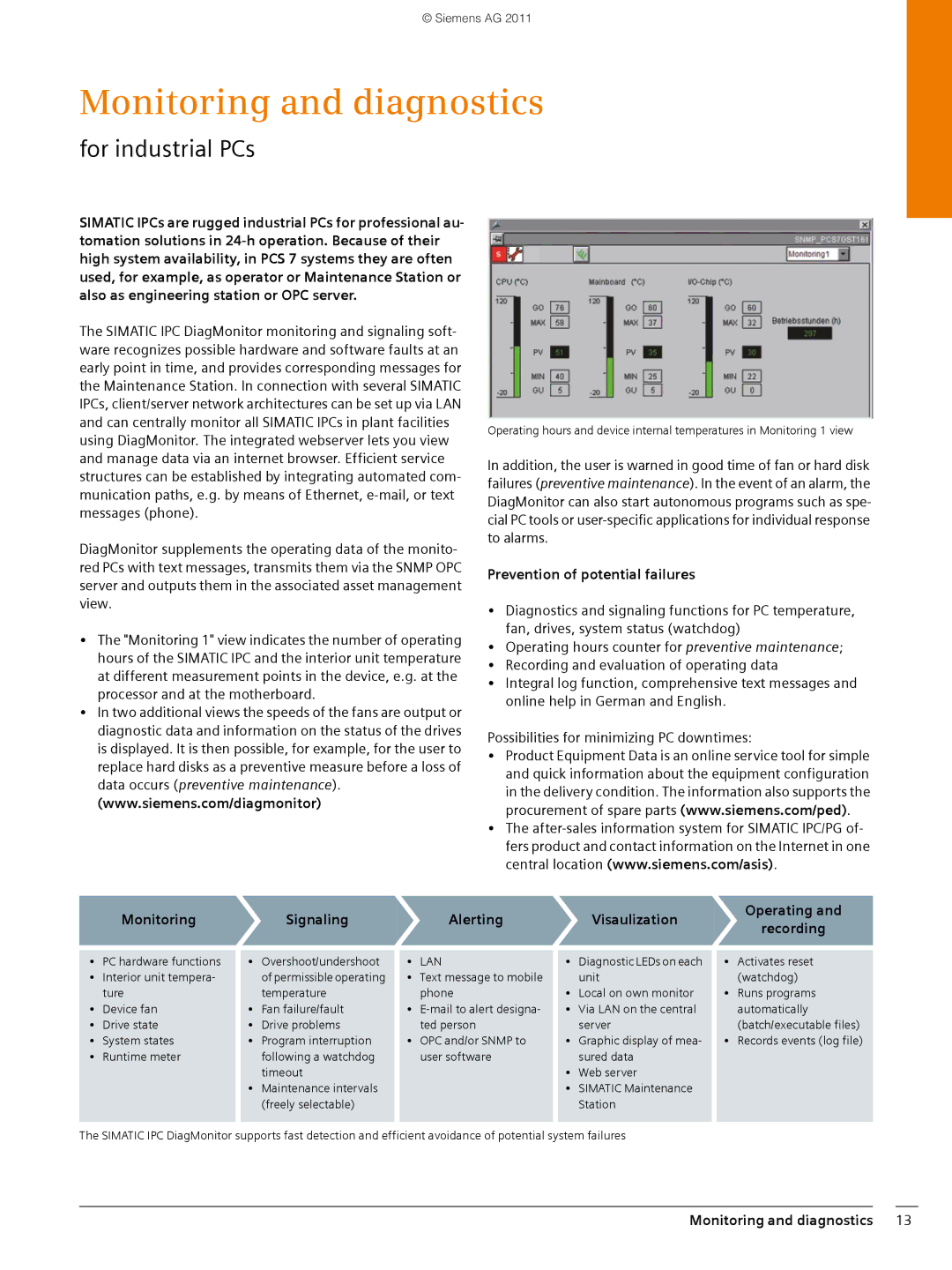

•The "Monitoring 1" view indicates the number of operating hours of the SIMATIC IPC and the interior unit temperature at different measurement points in the device, e.g. at the processor and at the motherboard.

•In two additional views the speeds of the fans are output or diagnostic data and information on the status of the drives is displayed. It is then possible, for example, for the user to replace hard disks as a preventive measure before a loss of data occurs (preventive maintenance).

(www.siemens.com/diagmonitor)

Operating hours and device internal temperatures in Monitoring 1 view

In addition, the user is warned in good time of fan or hard disk failures (preventive maintenance). In the event of an alarm, the DiagMonitor can also start autonomous programs such as spe- cial PC tools or

Prevention of potential failures

•Diagnostics and signaling functions for PC temperature, fan, drives, system status (watchdog)

•Operating hours counter for preventive maintenance;

•Recording and evaluation of operating data

•Integral log function, comprehensive text messages and online help in German and English.

Possibilities for minimizing PC downtimes:

•Product Equipment Data is an online service tool for simple and quick information about the equipment configuration in the delivery condition. The information also supports the procurement of spare parts (www.siemens.com/ped).

•The

Monitoring | Signaling | Alerting | Visaulization | Operating and | |

recording | |||||

|

|

|

| ||

|

|

|

|

|

•PC hardware functions

•Interior unit tempera- ture

•Device fan

•Drive state

•System states

•Runtime meter

•Overshoot/undershoot of permissible operating temperature

•Fan failure/fault

•Drive problems

•Program interruption following a watchdog timeout

•Maintenance intervals (freely selectable)

•LAN

•Text message to mobile phone

•

•OPC and/or SNMP to user software

•Diagnostic LEDs on each unit

•Local on own monitor

•Via LAN on the central server

•Graphic display of mea- sured data

•Web server

•SIMATIC Maintenance Station

•Activates reset (watchdog)

•Runs programs automatically (batch/executable files)

•Records events (log file)

The SIMATIC IPC DiagMonitor supports fast detection and efficient avoidance of potential system failures