© Siemens AG 2011

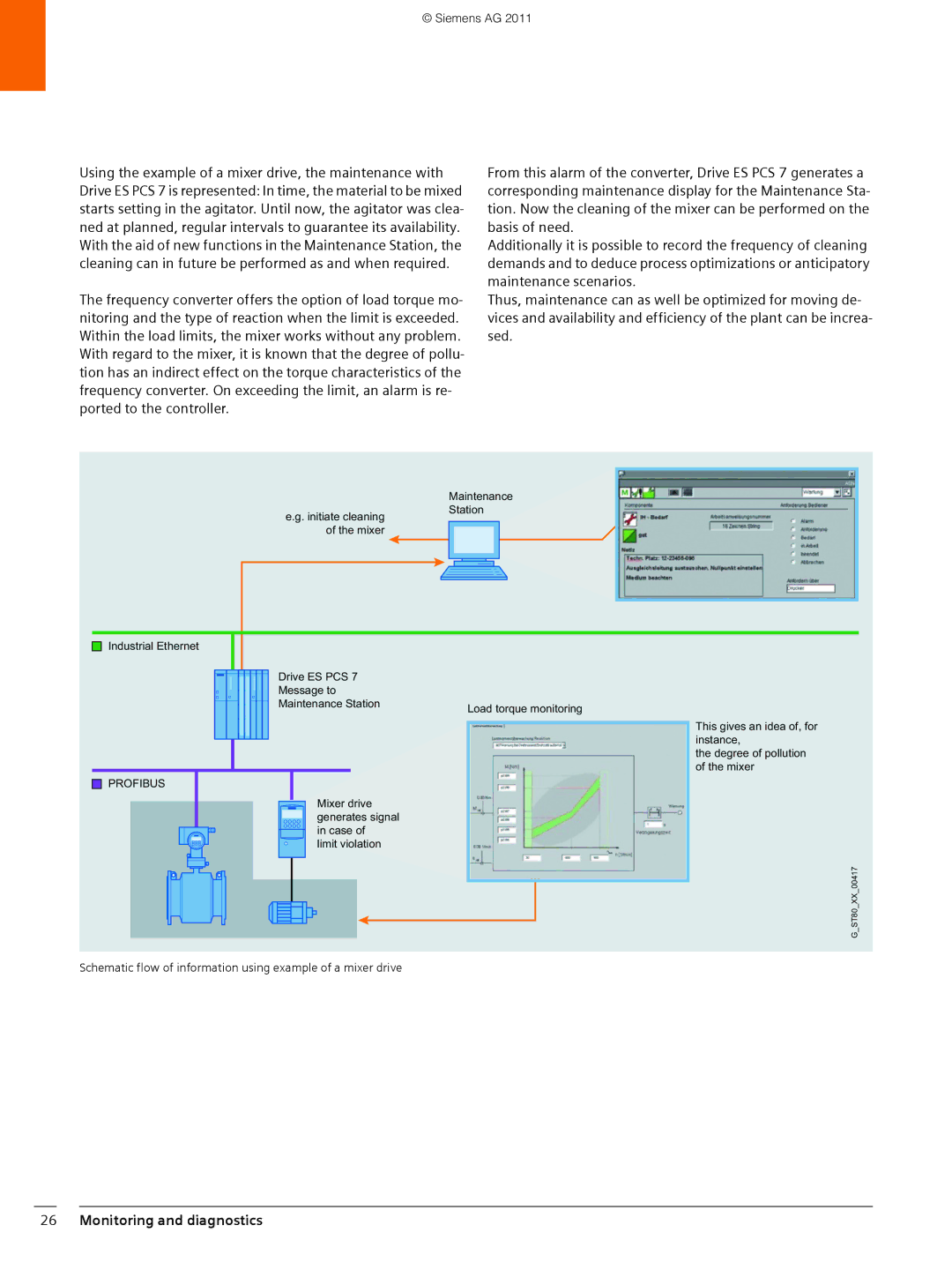

Using the example of a mixer drive, the maintenance with Drive ES PCS 7 is represented: In time, the material to be mixed starts setting in the agitator. Until now, the agitator was clea- ned at planned, regular intervals to guarantee its availability. With the aid of new functions in the Maintenance Station, the cleaning can in future be performed as and when required.

The frequency converter offers the option of load torque mo- nitoring and the type of reaction when the limit is exceeded. Within the load limits, the mixer works without any problem. With regard to the mixer, it is known that the degree of pollu- tion has an indirect effect on the torque characteristics of the frequency converter. On exceeding the limit, an alarm is re- ported to the controller.

From this alarm of the converter, Drive ES PCS 7 generates a corresponding maintenance display for the Maintenance Sta- tion. Now the cleaning of the mixer can be performed on the basis of need.

Additionally it is possible to record the frequency of cleaning demands and to deduce process optimizations or anticipatory maintenance scenarios.

Thus, maintenance can as well be optimized for moving de- vices and availability and efficiency of the plant can be increa- sed.

e.g. initiate cleaning of the mixer

Maintenance Station

Industrial Ethernet

Drive ES PCS 7 |

|

Message to |

|

Maintenance Station | Load torque monitoring |

|

PROFIBUS

Mixer drive generates signal in case of

limit violation

This gives an idea of, for instance,

the degree of pollution of the mixer

G_ST80_XX_00417