SM 1619X04717 04-10:SM 1619X04717 04-10 4/22/10 9:57 AM Page 9

Operating Instructions

VARIABLE SPEED CONTROLLED

TRIGGER SWITCH

Your tool is equipped with a variable speed trigger switch. The tool speed can be controlled from the minimum to the maximum nameplate RPM by the pressure you apply to the trigger. Apply more pressure to increase the speed and release pressure to decrease speed. This accurate speed control enables you to drill without center punching. It also permits you to use as a power screwdriver. Bits are available for driving screws as well as running bolts and nuts.

FORWARD/REVERSING LEVER &

TRIGGER LOCK

After tool use, lock trigger in “OFF” position to help prevent

accidental starts and accidental discharge.

Your tool is equipped with a forward/ reversing lever and trigger lock located above the trigger (Fig. 1). This lever was designed for changing rotation of the bit, and for locking the trigger in an “OFF” position.

For forward rotation, (with chuck pointed away from you) move the lever to the far left.

For reverse rotation move the lever to the far right. To activate trigger lock move lever to the center off position.

! | CAUTION | Do not change direction of | |

rotation until the tool comes | |||

|

|

to a complete stop. Shifting during rotation of the chuck can cause damage to the tool.

ADJUSTABLE CLUTCH

Your tool features 16 clutch settings. Output torque will increase as the clutch ring, is

INSERTING BITS

Move reverse switch lever to the center “OFF” position. Remove battery pack and rotate the clutch ring to the drill bit symbol

“![]()

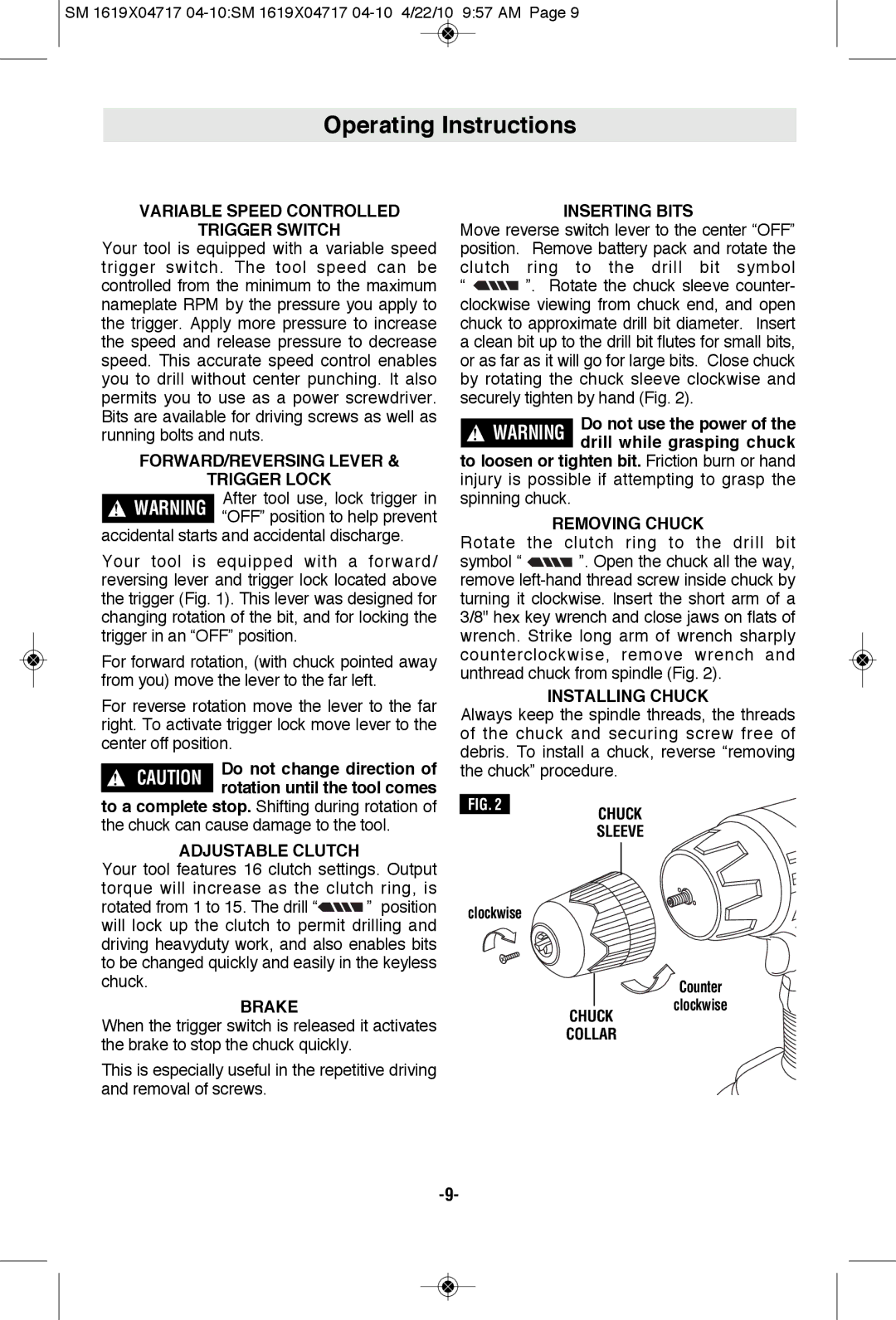

![]() ”. Rotate the chuck sleeve counter- clockwise viewing from chuck end, and open chuck to approximate drill bit diameter. Insert a clean bit up to the drill bit flutes for small bits, or as far as it will go for large bits. Close chuck by rotating the chuck sleeve clockwise and securely tighten by hand (Fig. 2).

”. Rotate the chuck sleeve counter- clockwise viewing from chuck end, and open chuck to approximate drill bit diameter. Insert a clean bit up to the drill bit flutes for small bits, or as far as it will go for large bits. Close chuck by rotating the chuck sleeve clockwise and securely tighten by hand (Fig. 2).

Do not use the power of the ! WARNING drill while grasping chuck

to loosen or tighten bit. Friction burn or hand injury is possible if attempting to grasp the spinning chuck.

REMOVING CHUCK

Rotate the clutch ring to the drill bit

symbol “ ![]()

![]() ”. Open the chuck all the way, remove

”. Open the chuck all the way, remove

INSTALLING CHUCK

Always keep the spindle threads, the threads of the chuck and securing screw free of debris. To install a chuck, reverse “re moving the chuck” procedure.

FIG. 2

CHUCK

SLEEVE

rotated from 1 to 15. The drill “![]()

![]() ” position will lock up the clutch to permit drilling and driving heavyduty work, and also enables bits to be changed quickly and easily in the keyless chuck.

” position will lock up the clutch to permit drilling and driving heavyduty work, and also enables bits to be changed quickly and easily in the keyless chuck.

BRAKE

When the trigger switch is released it activates

clockwise

CHUCK

![]()

![]()

![]() Counter clockwise

Counter clockwise

the brake to stop the chuck quickly.

This is especially useful in the repetitive driving and removal of screws.

COLLAR