Section 3 - OPERATING INSTRUCTIONS

3.1PRE-START CHECK LIST

Make the following checks and perform the service required before each

3.1.1.Check tires and add or release air as needed to bring pressure to 12 psi in drive tires. Pressure in front caster wheels should be 25 psi.

3.1.2.Check guards, deflectors and covers to make sure all are in place and securely tightened.

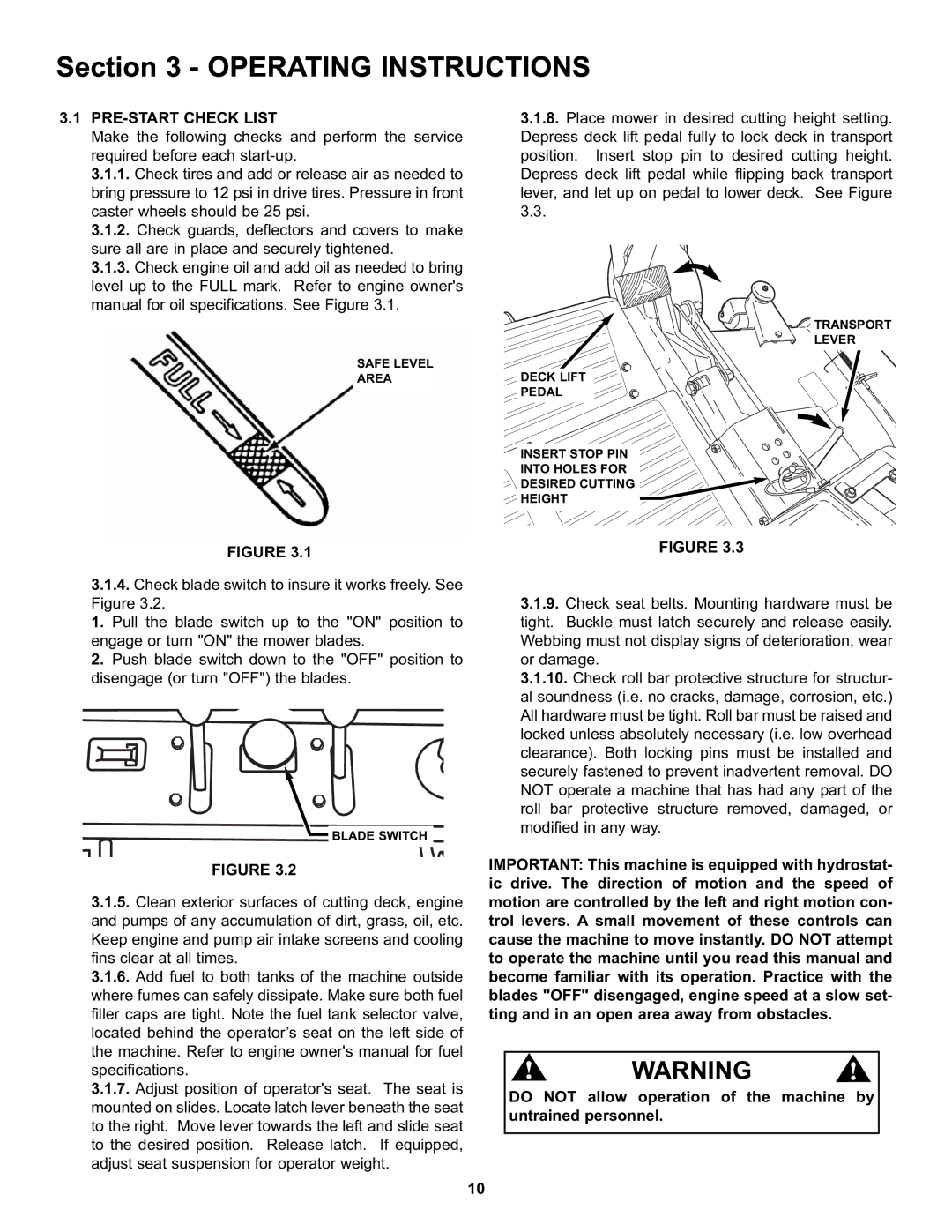

3.1.3.Check engine oil and add oil as needed to bring level up to the FULL mark. Refer to engine owner's manual for oil specifications. See Figure 3.1.

SAFE LEVEL

AREA

3.1.8.Place mower in desired cutting height setting. Depress deck lift pedal fully to lock deck in transport position. Insert stop pin to desired cutting height. Depress deck lift pedal while flipping back transport lever, and let up on pedal to lower deck. See Figure 3.3.

TRANSPORT

LEVER

DECK LIFT

PEDAL

INSERT STOP PIN

INTO HOLES FOR

DESIRED CUTTING

HEIGHT

FIGURE 3.1

3.1.4.Check blade switch to insure it works freely. See Figure 3.2.

1. Pull the blade switch up to the "ON" position to engage or turn "ON" the mower blades.

2. Push blade switch down to the "OFF" position to disengage (or turn "OFF") the blades.

BLADE SWITCH

FIGURE 3.2

3.1.5.Clean exterior surfaces of cutting deck, engine and pumps of any accumulation of dirt, grass, oil, etc. Keep engine and pump air intake screens and cooling fins clear at all times.

3.1.6.Add fuel to both tanks of the machine outside where fumes can safely dissipate. Make sure both fuel filler caps are tight. Note the fuel tank selector valve, located behind the operator’s seat on the left side of the machine. Refer to engine owner's manual for fuel specifications.

3.1.7.Adjust position of operator's seat. The seat is mounted on slides. Locate latch lever beneath the seat to the right. Move lever towards the left and slide seat to the desired position. Release latch. If equipped, adjust seat suspension for operator weight.

FIGURE 3.3

3.1.9.Check seat belts. Mounting hardware must be tight. Buckle must latch securely and release easily. Webbing must not display signs of deterioration, wear or damage.

3.1.10.Check roll bar protective structure for structur- al soundness (i.e. no cracks, damage, corrosion, etc.) All hardware must be tight. Roll bar must be raised and locked unless absolutely necessary (i.e. low overhead clearance). Both locking pins must be installed and securely fastened to prevent inadvertent removal. DO NOT operate a machine that has had any part of the roll bar protective structure removed, damaged, or modified in any way.

IMPORTANT: This machine is equipped with hydrostat- ic drive. The direction of motion and the speed of motion are controlled by the left and right motion con- trol levers. A small movement of these controls can cause the machine to move instantly. DO NOT attempt to operate the machine until you read this manual and become familiar with its operation. Practice with the blades "OFF" disengaged, engine speed at a slow set- ting and in an open area away from obstacles.

! | WARNING | ! |

DO NOT allow operation of the machine by untrained personnel.

10