For Machines Mfg. Since 8/09 | S E R V I C E | Model SB1020 |

SERVICE

Blade Brush

The Model SB1020 has a blade brush to help keep metal chips off the blade wheels. It will wear over time and require

Tools Needed | Qty |

Hex Wrench 4mm | .................................................. 1 |

To adjust the blade brush:

1.DISCONNECT BANDSAW FROM POWER!

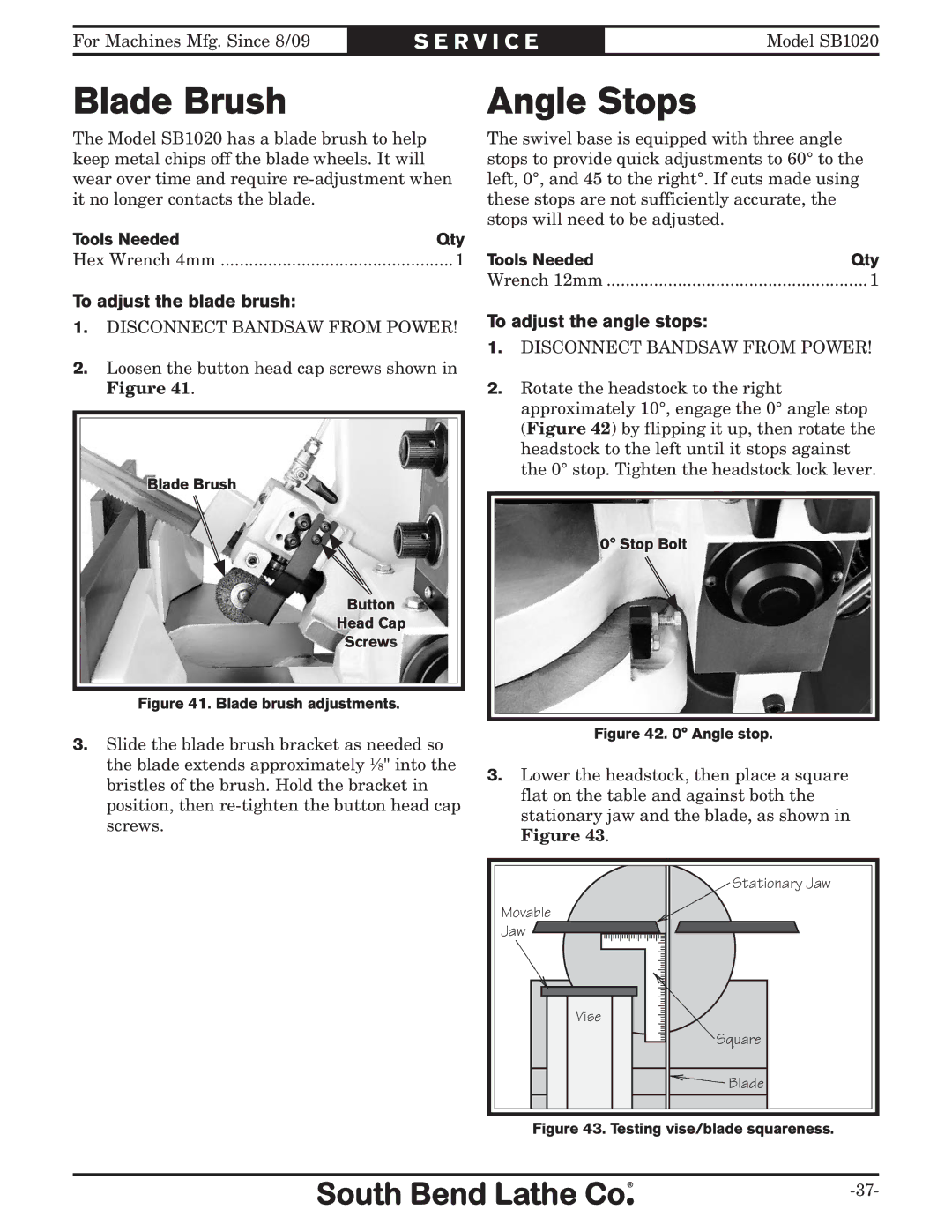

2.Loosen the button head cap screws shown in Figure 41.

Blade Brush

Button

Head Cap

Screws

Figure 41. Blade brush adjustments.

3.Slide the blade brush bracket as needed so the blade extends approximately 1⁄8" into the bristles of the brush. Hold the bracket in position, then

Angle Stops

The swivel base is equipped with three angle stops to provide quick adjustments to 60° to the left, 0°, and 45 to the right°. If cuts made using these stops are not sufficiently accurate, the stops will need to be adjusted.

Tools Needed | Qty |

Wrench 12mm | ........................................................ 1 |

To adjust the angle stops:

1.DISCONNECT BANDSAW FROM POWER!

2.Rotate the headstock to the right approximately 10°, engage the 0° angle stop (Figure 42) by flipping it up, then rotate the headstock to the left until it stops against the 0° stop. Tighten the headstock lock lever.

0° Stop Bolt

Figure 42. 0° Angle stop.

3.Lower the headstock, then place a square flat on the table and against both the stationary jaw and the blade, as shown in Figure 43.

Stationary Jaw |

Movable |

Jaw |

Vise |

Square |

Blade |