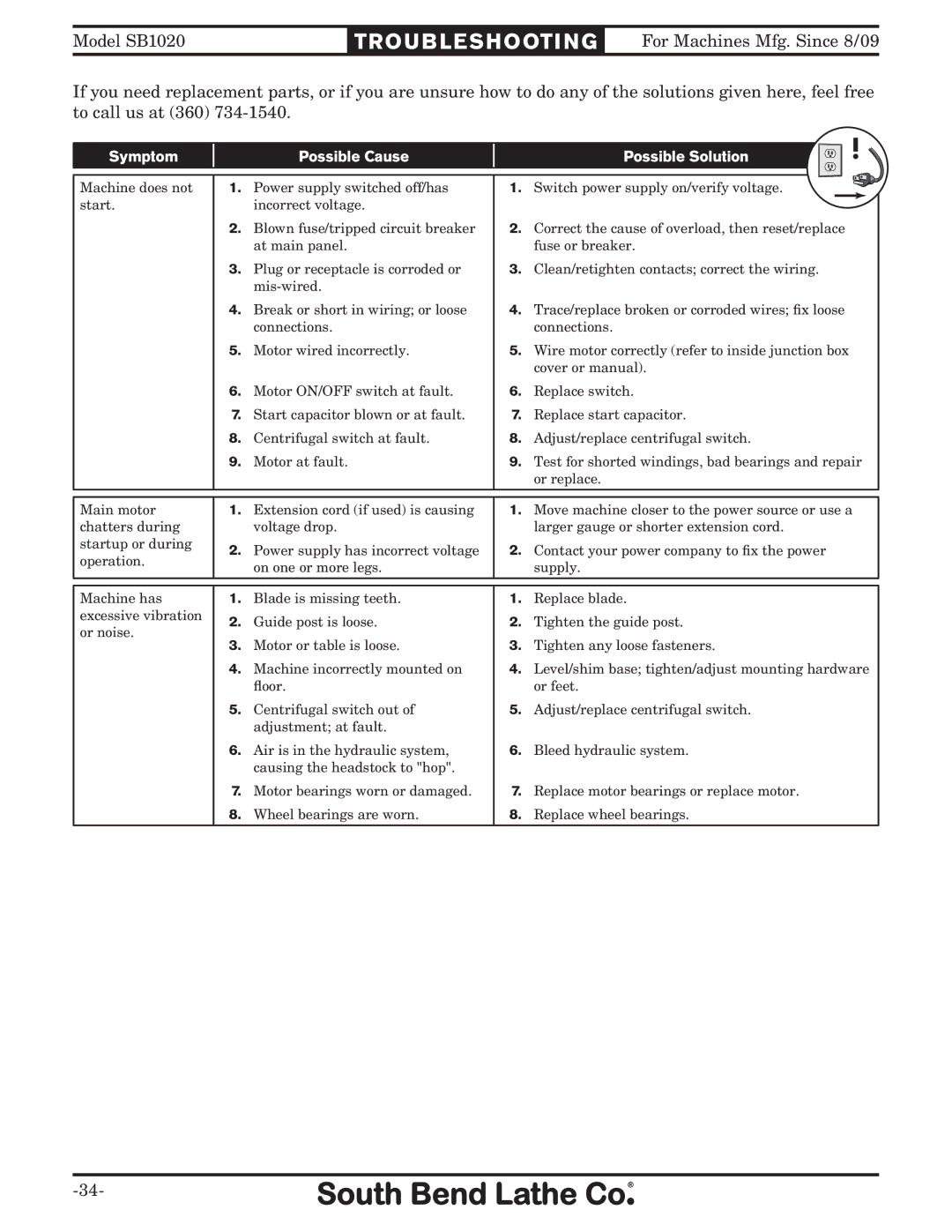

Model SB1020 | TROUBLESHOOTING | For Machines Mfg. Since 8/09 |

TROUBLESHOOTING

If you need replacement parts, or if you are unsure how to do any of the solutions given here, feel free to call us at (360)

Symptom

Possible Cause

Possible Solution | ! |

Machine does not | 1. Power supply switched off/has | 1. Switch power supply on/verify voltage. |

start. | incorrect voltage. |

|

2.Blown fuse/tripped circuit breaker 2. Correct the cause of overload, then reset/replace

at main panel. | fuse or breaker. |

3.Plug or receptacle is corroded or 3. Clean/retighten contacts; correct the wiring.

4.Break or short in wiring; or loose 4. Trace/replace broken or corroded wires; fix loose

connections. | connections. |

5.Motor wired incorrectly.5. Wire motor correctly (refer to inside junction box cover or manual).

| 6. | Motor ON/OFF switch at fault. | 6. | Replace switch. | |

| 7. | Start capacitor blown or at fault. | 7. | Replace start capacitor. | |

| 8. | Centrifugal switch at fault. | 8. | Adjust/replace centrifugal switch. | |

| 9. | Motor at fault. | 9. | Test for shorted windings, bad bearings and repair | |

|

|

|

| or replace. | |

|

|

|

|

| |

|

|

|

|

| |

Main motor | 1. | Extension cord (if used) is causing | 1. | Move machine closer to the power source or use a | |

chatters during |

| voltage drop. |

| larger gauge or shorter extension cord. | |

startup or during | 2. | Power supply has incorrect voltage | 2. | Contact your power company to fix the power | |

operation. | |||||

| on one or more legs. |

| supply. | ||

|

|

| |||

|

|

|

|

| |

|

|

|

|

| |

Machine has | 1. | Blade is missing teeth. | 1. | Replace blade. | |

excessive vibration | 2. | Guide post is loose. | 2. | Tighten the guide post. | |

or noise. | |||||

3. | Motor or table is loose. | 3. | Tighten any loose fasteners. | ||

|

4.Machine incorrectly mounted on 4. Level/shim base; tighten/adjust mounting hardware

| floor. |

| or feet. |

5. | Centrifugal switch out of | 5. | Adjust/replace centrifugal switch. |

| adjustment; at fault. |

|

|

6. | Air is in the hydraulic system, | 6. | Bleed hydraulic system. |

| causing the headstock to "hop". |

|

|

7.Motor bearings worn or damaged. 7. Replace motor bearings or replace motor.

8. Wheel bearings are worn. | 8. Replace wheel bearings. |