For Machines Mfg. Since 8/09 | O P E R A T I O N | Model SB1020 |

Description of Controls & Components

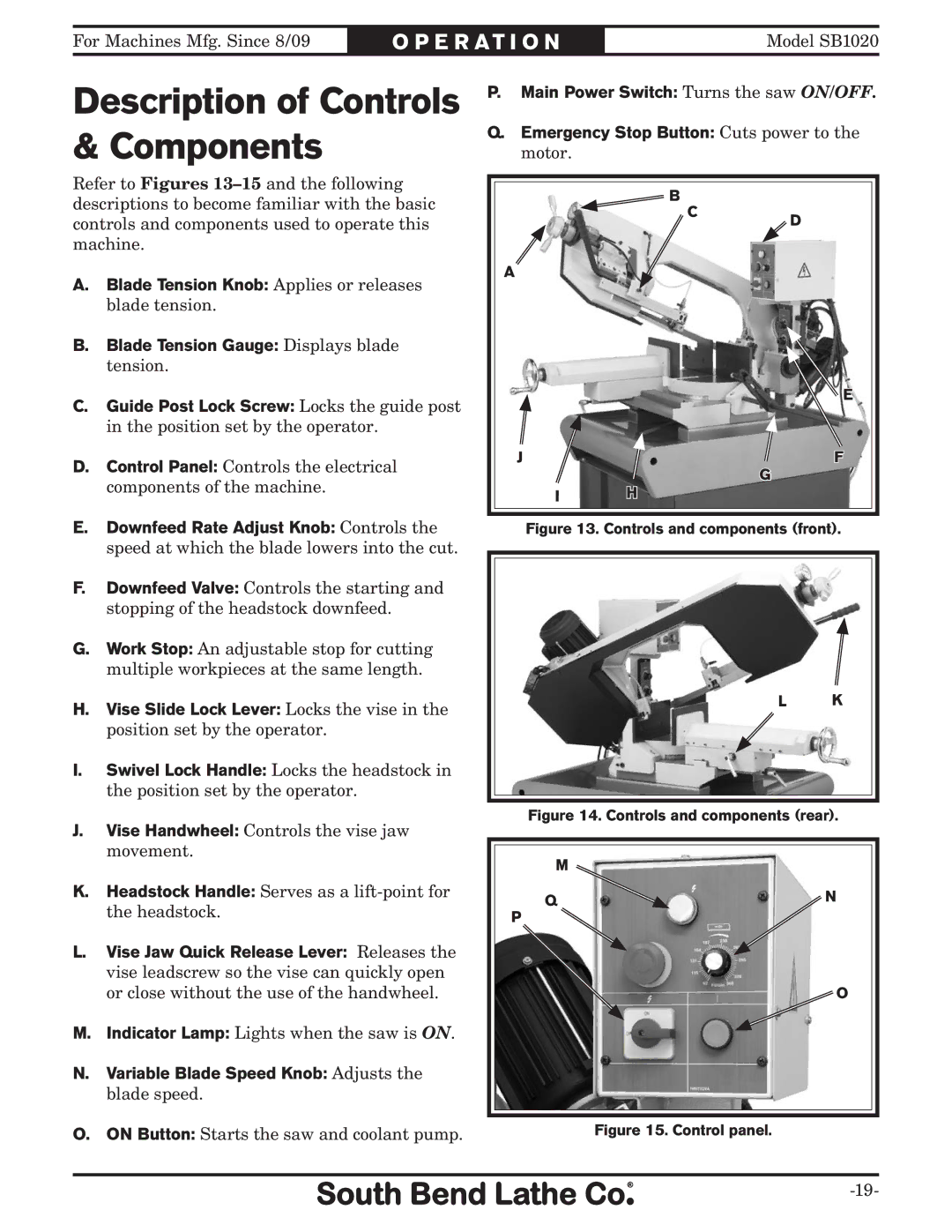

Refer to Figures

A. | Blade Tension Knob: Applies or releases |

| blade tension. |

B. | Blade Tension Gauge: Displays blade |

| tension. |

C. | Guide Post Lock Screw: Locks the guide post |

| in the position set by the operator. |

D. | Control Panel: Controls the electrical |

| components of the machine. |

E. | Downfeed Rate Adjust Knob: Controls the |

| speed at which the blade lowers into the cut. |

F. | Downfeed Valve: Controls the starting and |

| stopping of the headstock downfeed. |

G. | Work Stop: An adjustable stop for cutting |

| multiple workpieces at the same length. |

H. | Vise Slide Lock Lever: Locks the vise in the |

| position set by the operator. |

I. | Swivel Lock Handle: Locks the headstock in |

| the position set by the operator. |

J. | Vise Handwheel: Controls the vise jaw |

| movement. |

P.Main Power Switch: Turns the saw ON/OFF.

Q.Emergency Stop Button: Cuts power to the motor.

B

CD

A

E![]()

![]()

![]()

J![]() F

F![]()

![]() G

G

I H![]()

![]()

Figure 13. Controls and components (front).

L![]()

![]() K

K

Figure 14. Controls and components (rear).

K. | Headstock Handle: Serves as a |

| the headstock. |

L. | Vise Jaw Quick Release Lever: Releases the |

| vise leadscrew so the vise can quickly open |

| or close without the use of the handwheel. |

M. | Indicator Lamp: Lights when the saw is ON. |

N. | Variable Blade Speed Knob: Adjusts the |

| blade speed. |

O. | ON Button: Starts the saw and coolant pump. |

P

M

Q![]()

![]() N

N

![]() O

O