Model SB1020 | M A I N T E N A N C E | For Machines Mfg. Since 8/09 |

MaintenanceAINTENANCESchedule

! | Always disconnect |

| machine from power before |

| performing maintenance or |

| serious personal injury may |

| result. |

For optimum performance from your machine, follow this maintenance schedule and refer to any specific instructions given in this section.

Daily

•Check/correct loose mounting bolts.

•Check/correct damaged or dull saw blade.

•Check/correct worn or damaged wires.

•Clean/protect table.

•Clean metal chips from upper and lower wheel areas, and empty the chip chute.

•Correct any other unsafe condition.

Monthly

•Lubricate all components outlined in this section, with the exception of the gearbox.

•Monitor gearbox oil level by removing the fill plug and checking that the oil level is even with the fill hole (with headstock lowered)

Yearly

•Lubricate gearbox.

Cleaning

Use a brush and a shop vacuum to remove chips and other debris from the machine. Keep the

Periodically remove the blade and thoroughly clean all metal chips or

Lubrication

Before applying lubricant to any area, wipe the area clean to avoid contamination.

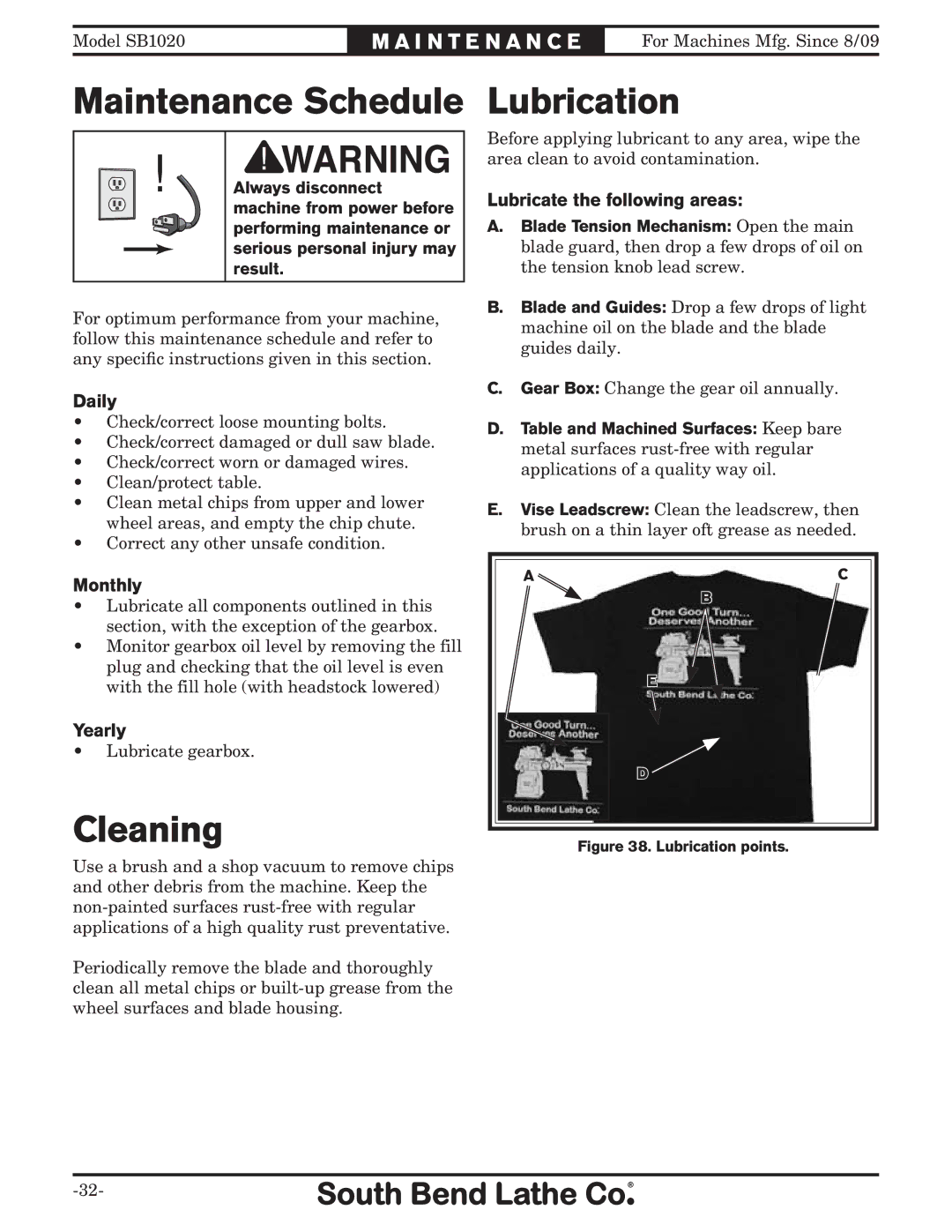

Lubricate the following areas:

A.Blade Tension Mechanism: Open the main blade guard, then drop a few drops of oil on the tension knob lead screw.

B.Blade and Guides: Drop a few drops of light machine oil on the blade and the blade guides daily.

C.Gear Box: Change the gear oil annually.

D.Table and Machined Surfaces: Keep bare metal surfaces

E.Vise Leadscrew: Clean the leadscrew, then brush on a thin layer oft grease as needed.

AC ![]() B

B

E![]()

![]()

![]()

D ![]()