For Machines Mfg. Since 8/09 | O P E R A T I O N | Model SB1027 |

3.Press the spindle speed range lever shown in Figure 34 toward the head to release the detent pin from the detent plate, move selector so that the pin is over the other detent, then release the selector.

—When the lever is pointing to the rear and the front detent is engaged, the low speed range is selected. Conversely, when the lever is pointing toward the front and the rear detent is engaged, the high speed range is selected.

Note: It may be necessary to turn the spindle by hand as you move the range lever to enable the gears to mesh.

High![]()

![]()

![]() Low

Low

Detent

Spindle ![]()

![]() Plate

Plate

Speed

Range

Lever

Figure 34. Spindle speed range selector.

Setting Spindle Speed

Use the spindle speed dial and display (see Figure 35) to set the required spindle speed within the speed range selected.

The top values of the spindle speed display are for the high spindle speed range, and the bottom values are for the low range.

Speed

Display

Spindle

Speed ![]()

Dial

Figure 35. Spindle speed dial and display.

Downfeed Controls

Spindle downfeed movement on the mill is controlled by three mechanisms: 1) The coarse downfeed handle, 2) the fine downfeed handwheel, and 3) the

Using the Coarse Downfeed Handle

1.DISCONNECT MILL FROM POWER!

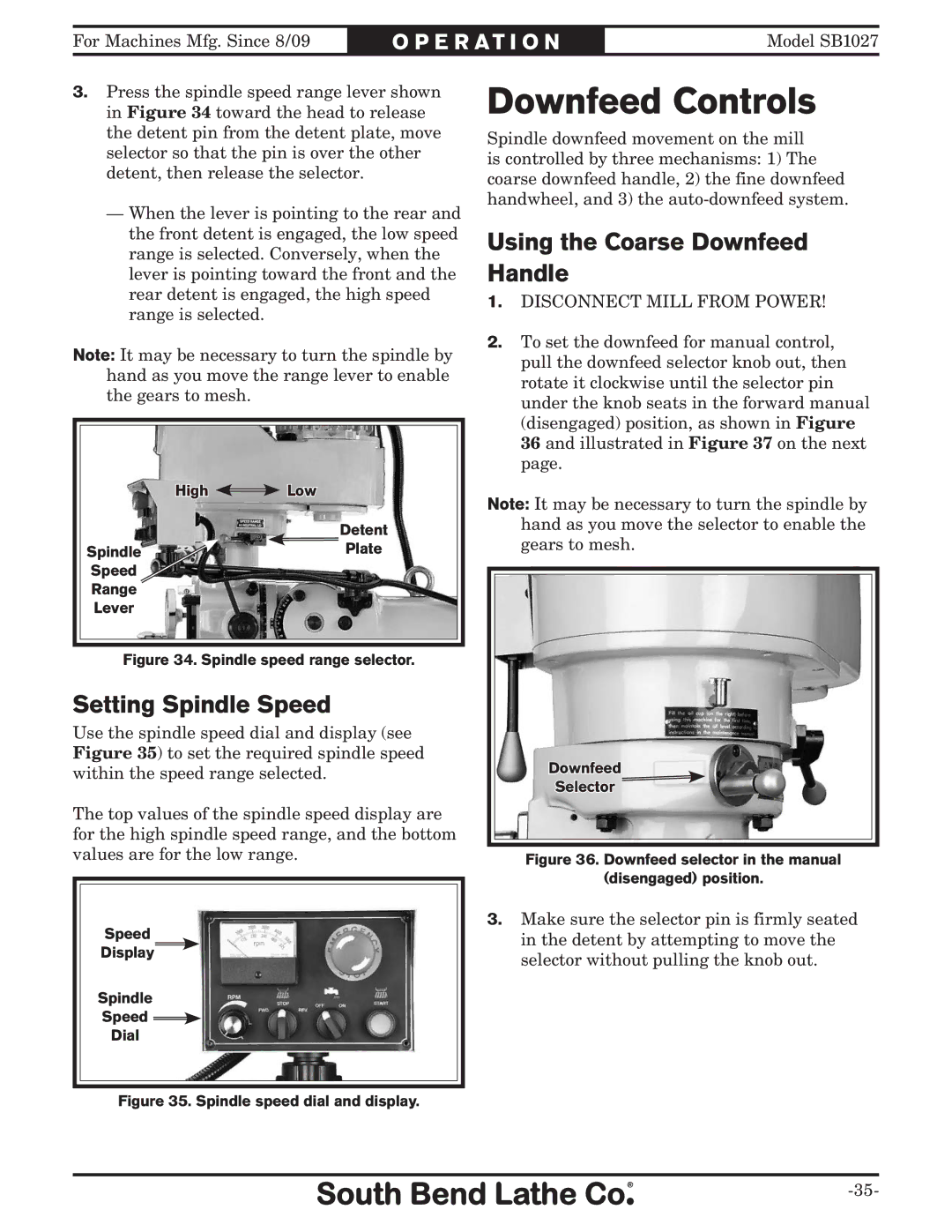

2.To set the downfeed for manual control, pull the downfeed selector knob out, then rotate it clockwise until the selector pin under the knob seats in the forward manual (disengaged) position, as shown in Figure 36 and illustrated in Figure 37 on the next page.

Note: It may be necessary to turn the spindle by hand as you move the selector to enable the gears to mesh.

Downfeed

Selector ![]()

Figure 36. Downfeed selector in the manual

(disengaged) position.

3.Make sure the selector pin is firmly seated in the detent by attempting to move the selector without pulling the knob out.