Model SB1027 | P R E P A R A T I O N | For Machines Mfg. Since 8/09 |

5.Loosen the hose clamp screws above the coolant return screens in the base (see Figure 13 on the previous page), insert the hoses so that they will drain into the screens, then

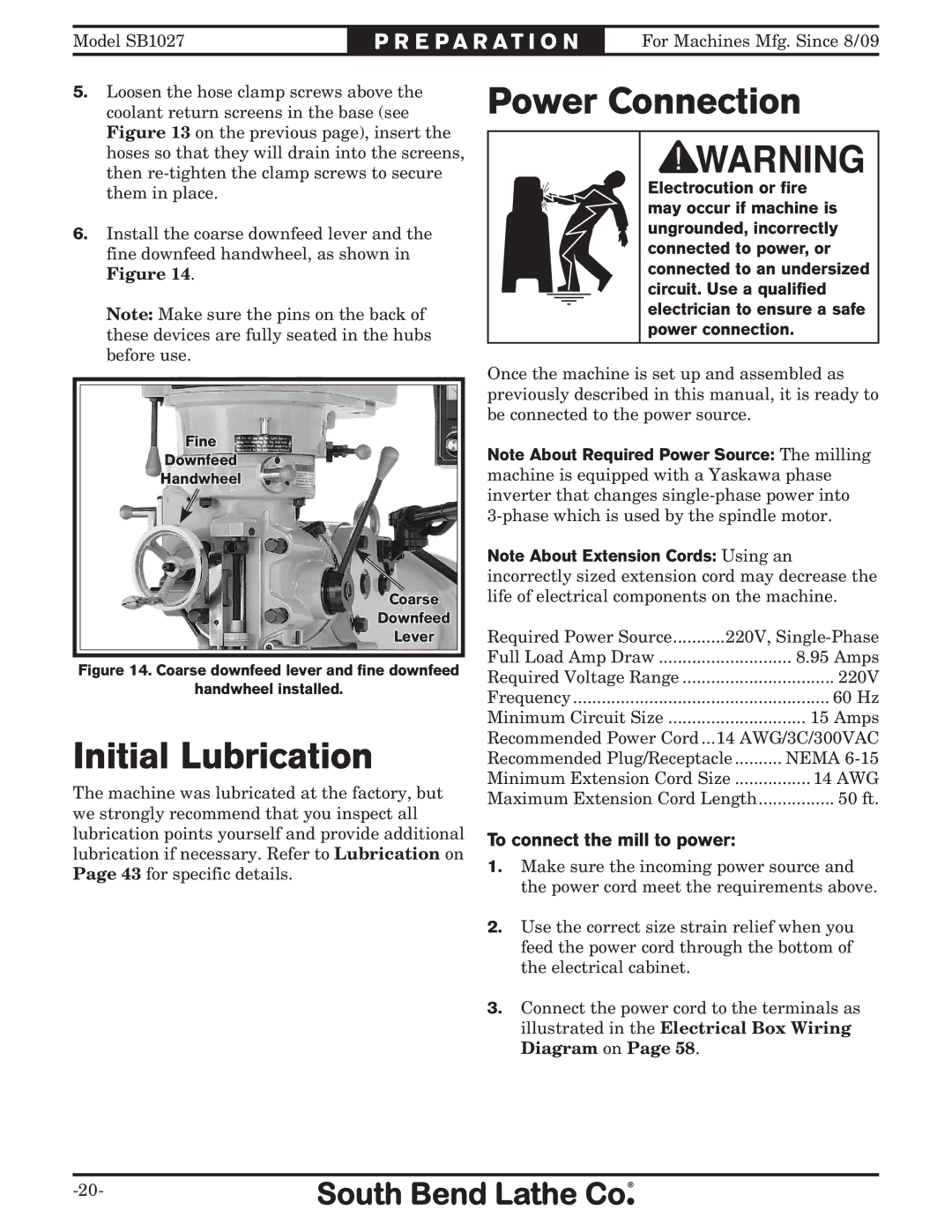

6.Install the coarse downfeed lever and the fine downfeed handwheel, as shown in Figure 14.

Note: Make sure the pins on the back of these devices are fully seated in the hubs before use.

Fine

Downfeed

Handwheel![]()

![]()

Coarse

Downfeed

Lever

Figure 14. Coarse downfeed lever and fine downfeed

handwheel installed.

Initial Lubrication

The machine was lubricated at the factory, but we strongly recommend that you inspect all lubrication points yourself and provide additional lubrication if necessary. Refer to Lubrication on Page 43 for specific details.

Power Connection

Electrocution or fire may occur if machine is ungrounded, incorrectly connected to power, or connected to an undersized circuit. Use a qualified electrician to ensure a safe power connection.

Once the machine is set up and assembled as previously described in this manual, it is ready to be connected to the power source.

Note About Required Power Source: The milling machine is equipped with a Yaskawa phase inverter that changes

Note About Extension Cords: Using an incorrectly sized extension cord may decrease the life of electrical components on the machine.

Required Power Source | 220V, | |

Full Load Amp Draw | 8.95 Amps | |

Required Voltage Range | 220V | |

Frequency | 60 Hz | |

Minimum Circuit Size | 15 Amps | |

Recommended Power Cord.... | 14 AWG/3C/300VAC | |

Recommended Plug/Receptacle | NEMA | |

Minimum Extension Cord Size | 14 AWG | |

Maximum Extension Cord Length | 50 ft. | |

To connect the mill to power:

1.Make sure the incoming power source and the power cord meet the requirements above.

2.Use the correct size strain relief when you feed the power cord through the bottom of the electrical cabinet.

3.Connect the power cord to the terminals as illustrated in the Electrical Box Wiring Diagram on Page 58.