|

| ||

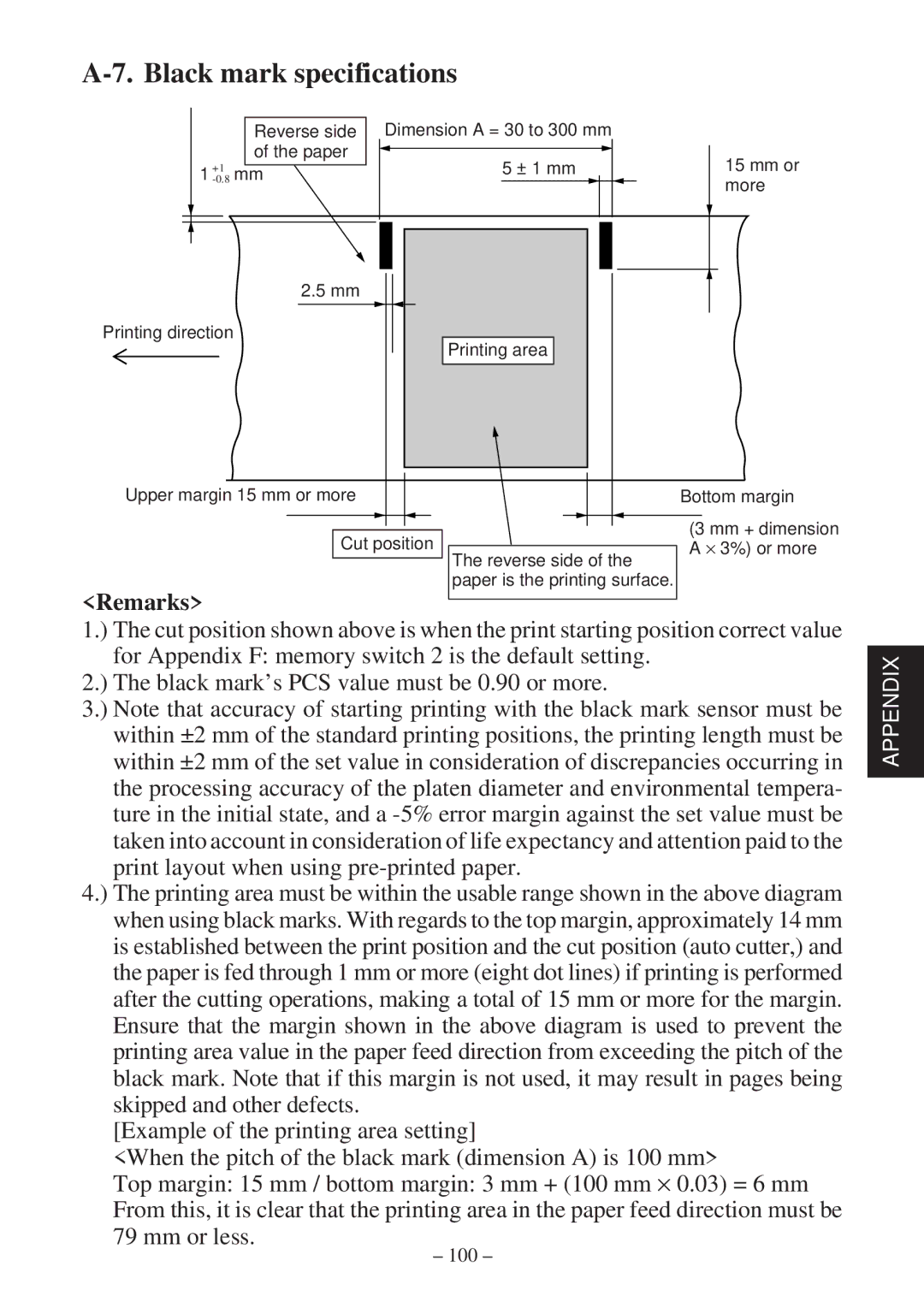

| Reverse side | Dimension A = 30 to 300 mm |

|

| of the paper | 5 ± 1 mm | 15 mm or |

+1 | mm | ||

1 |

| more | |

|

|

| |

| 2.5 mm |

|

|

Printing direction |

| Printing area |

|

|

|

| |

Upper margin 15 mm or more |

| Bottom margin | |

| Cut position | (3 mm + dimension | |

| A × 3%) or more | ||

|

| The reverse side of the |

|

|

| paper is the printing surface. |

|

<Remarks>

1.) The cut position shown above is when the print starting position correct value for Appendix F: memory switch 2 is the default setting.

2.) The black mark’s PCS value must be 0.90 or more.

3.) Note that accuracy of starting printing with the black mark sensor must be within ±2 mm of the standard printing positions, the printing length must be within ±2 mm of the set value in consideration of discrepancies occurring in the processing accuracy of the platen diameter and environmental tempera- ture in the initial state, and a

4.) The printing area must be within the usable range shown in the above diagram when using black marks. With regards to the top margin, approximately 14 mm is established between the print position and the cut position (auto cutter,) and the paper is fed through 1 mm or more (eight dot lines) if printing is performed after the cutting operations, making a total of 15 mm or more for the margin. Ensure that the margin shown in the above diagram is used to prevent the printing area value in the paper feed direction from exceeding the pitch of the black mark. Note that if this margin is not used, it may result in pages being skipped and other defects.

[Example of the printing area setting]

<When the pitch of the black mark (dimension A) is 100 mm>

Top margin: 15 mm / bottom margin: 3 mm + (100 mm × 0.03) = 6 mm From this, it is clear that the printing area in the paper feed direction must be 79 mm or less.

APPENDIX

– 100 –