HORIZONTALLY VENTED UNIT HEATERS (CATEGORY I - U.S. RESIDENTIAL ONLY)

All venting of residential tubular unit heaters must comply with CSA International Requirement 10.96 U.S. for Unit Heaters for Residential Use (2nd Edition).

Category I horizontal venting arrangements are designed to be used with either single wall vent pipe or double wall (Type B) vent pipe. These arrangements must terminate external to the building using either single wall or double wall (Type B) vent. See Table 4 and Figures 13 and 14 for special installation requirements regarding these venting conditions.

An Amerivent Americap, Fields Starkap, or Metalbestos vent cap must be supplied by the customer for each power vented unit.

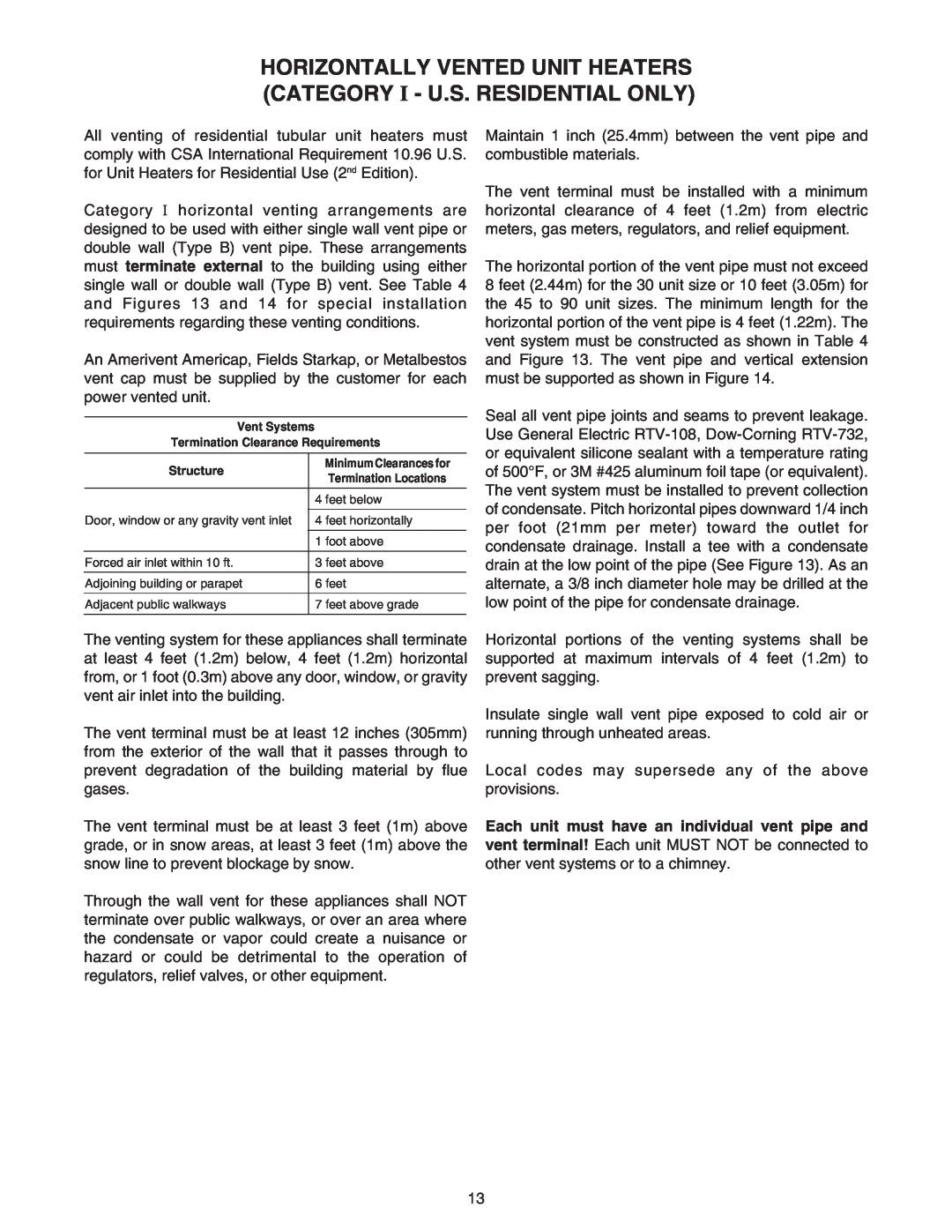

Vent Systems

Termination Clearance Requirements

Structure | Minimum Clearances for | ||

Termination Locations | |||

|

| ||

|

|

| |

|

| 4 feet below | |

|

|

| |

Door, window or any gravity vent inlet | 4 feet horizontally | ||

|

|

| |

|

| 1 foot above | |

|

| ||

Forced air inlet within 10 ft. | 3 feet above | ||

|

| ||

Adjoining building or parapet | 6 feet | ||

|

| ||

Adjacent public walkways | 7 feet above grade | ||

|

|

| |

The venting system for these appliances shall terminate at least 4 feet (1.2m) below, 4 feet (1.2m) horizontal from, or 1 foot (0.3m) above any door, window, or gravity vent air inlet into the building.

The vent terminal must be at least 12 inches (305mm) from the exterior of the wall that it passes through to prevent degradation of the building material by flue gases.

The vent terminal must be at least 3 feet (1m) above grade, or in snow areas, at least 3 feet (1m) above the snow line to prevent blockage by snow.

Through the wall vent for these appliances shall NOT terminate over public walkways, or over an area where the condensate or vapor could create a nuisance or hazard or could be detrimental to the operation of regulators, relief valves, or other equipment.

Maintain 1 inch (25.4mm) between the vent pipe and combustible materials.

The vent terminal must be installed with a minimum horizontal clearance of 4 feet (1.2m) from electric meters, gas meters, regulators, and relief equipment.

The horizontal portion of the vent pipe must not exceed 8 feet (2.44m) for the 30 unit size or 10 feet (3.05m) for the 45 to 90 unit sizes. The minimum length for the horizontal portion of the vent pipe is 4 feet (1.22m). The vent system must be constructed as shown in Table 4 and Figure 13. The vent pipe and vertical extension must be supported as shown in Figure 14.

Seal all vent pipe joints and seams to prevent leakage. Use General Electric

Horizontal portions of the venting systems shall be supported at maximum intervals of 4 feet (1.2m) to prevent sagging.

Insulate single wall vent pipe exposed to cold air or running through unheated areas.

Local codes may supersede any of the above provisions.

Each unit must have an individual vent pipe and vent terminal! Each unit MUST NOT be connected to other vent systems or to a chimney.

13