F R A M E D

P A N E L S

Refer to the Framed Panel Specifications on pages

FRAMED PANEL I N S TA L L AT I O N

PANEL I N S TA L L AT I O N

Before you begin installing panels, refer to the Panel Specifications for framed or overlay models and be sure you are working with the panel design called for in your installation. If your customer has chosen the stainless steel design, the unit has been shipped complete with a finished stainless steel look. It will not be necessary to install panels or handle hardware. In your final preparation for stain- less steel units, use a stainless steel cleaner to remove any marks. Abrasive cleaners should not be used, as they may scratch the surface.

If your customer has ordered either a framed or overlay model, you will be installing panels to give the unit the custom

FRAMED P A N E L S

If your customer has chosen a framed design application, make sure that the panels you are about to install match dimensions listed in the Framed Panel Specifications on pages

If the thickness of the custom panel is less than a 1/4" (6), back it up with a sheet of shim material to build the total thickness to a 1/4" (6). If the panel is thicker than a 1/4" (6), rout an edge around the panel to get a proper fit.

IMPORTANT NOTE: The weight of each panel cannot exceed 50 lbs (23 kg).

IMPORTANT NOTE: On all

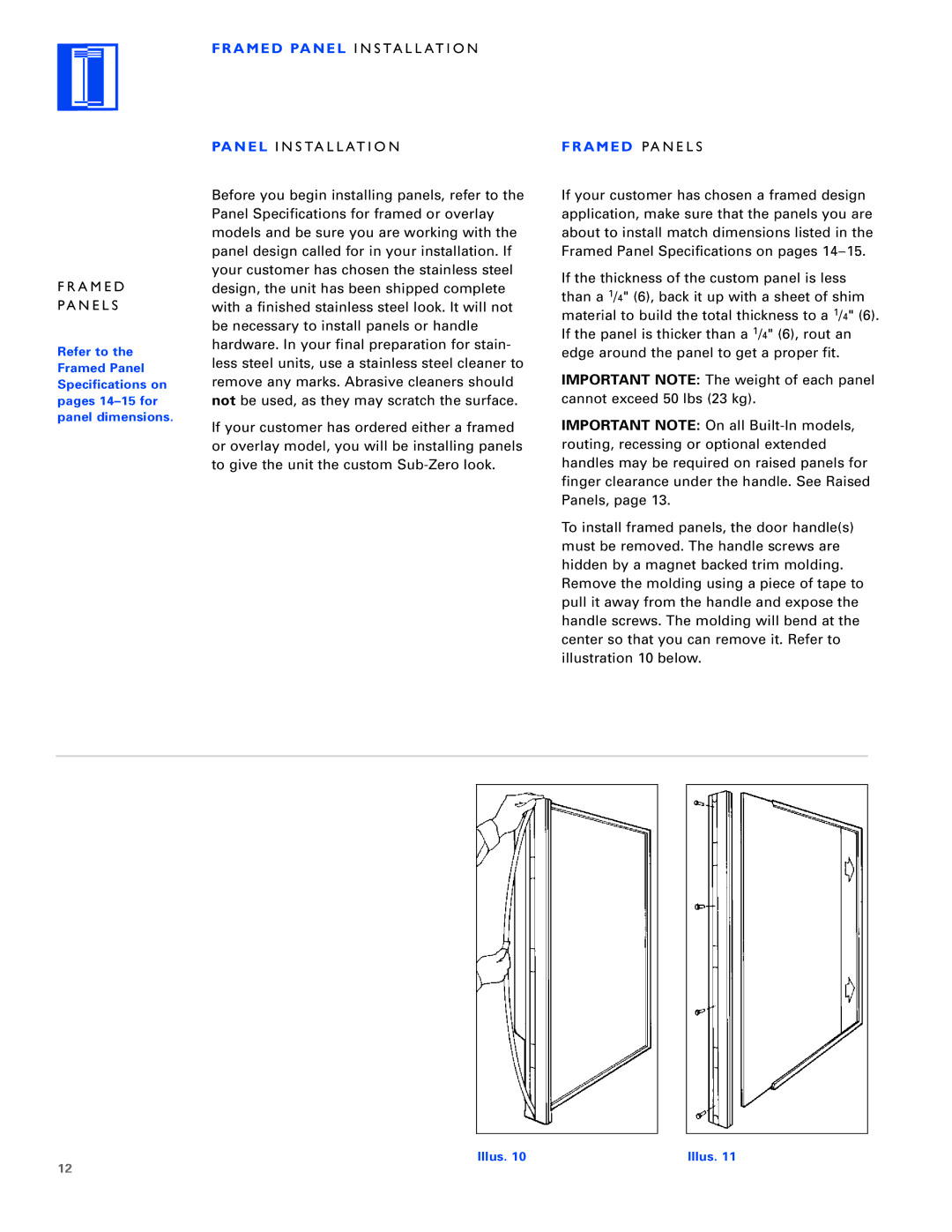

To install framed panels, the door handle(s) must be removed. The handle screws are hidden by a magnet backed trim molding. Remove the molding using a piece of tape to pull it away from the handle and expose the handle screws. The molding will bend at the center so that you can remove it. Refer to illustration 10 below.

Illus. 10 | Illus. 11 |

12