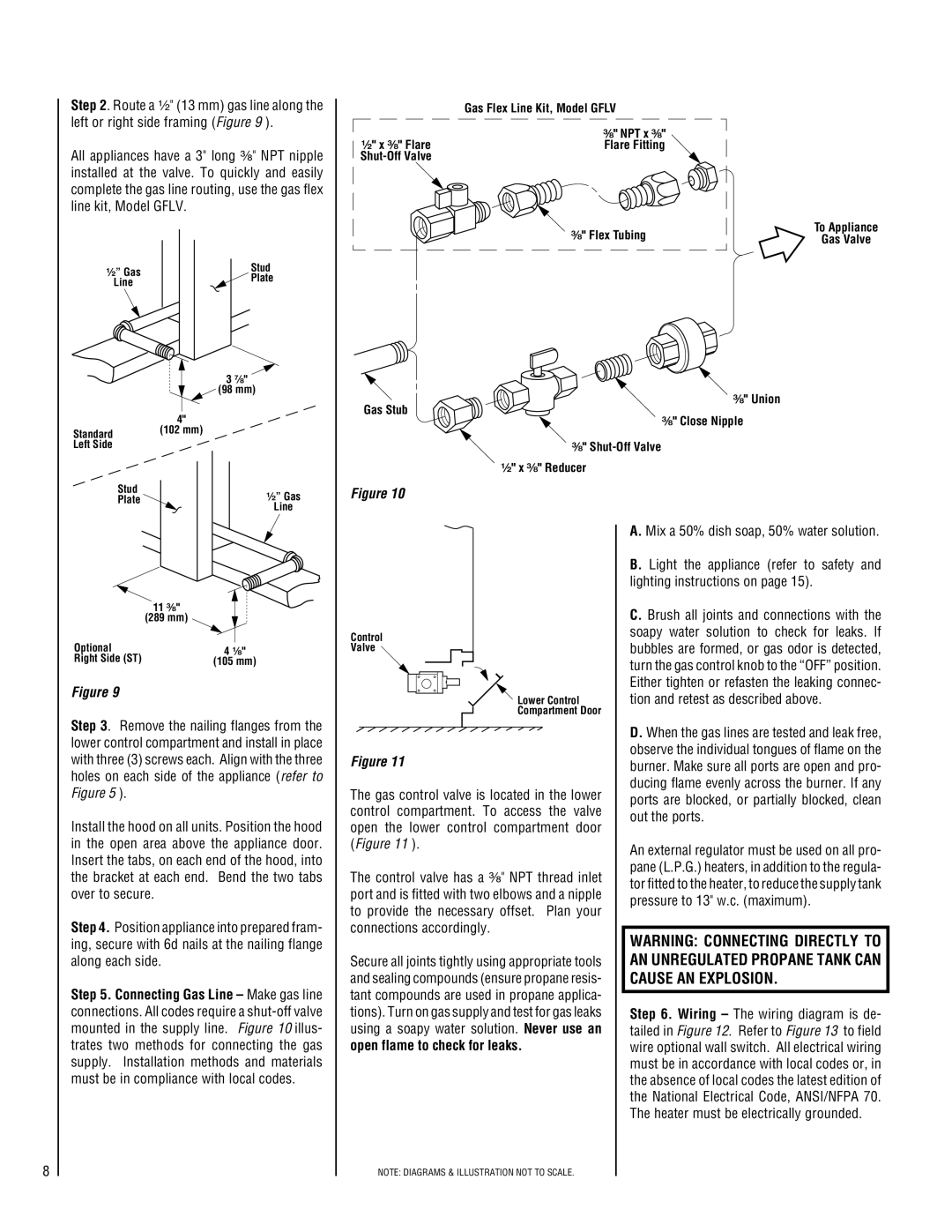

Step 2. Route a ¹⁄₂" (13 mm) gas line along the left or right side framing (Figure 9 ).

All appliances have a 3" long ³⁄₈" NPT nipple installed at the valve. To quickly and easily complete the gas line routing, use the gas flex line kit, Model GFLV.

¹⁄₂” Gas | Stud | |

Plate | ||

Line | ||

|

| 3 ⁷⁄₈" |

| (98 mm) |

| 4" |

Standard | (102 mm) |

Left Side |

|

Gas Flex Line Kit, Model GFLV

³ " NPT x ³ "

¹ " x ³ " FlareFlare Fitting

³ " Flex Tubing

³ " Union

Gas Stub

³ " Close Nipple

³ "

¹ " x ³ " Reducer

To Appliance

Gas Valve

Stud | ¹⁄₂” Gas | |

Plate | ||

Line | ||

|

11³⁄₈"

| (289 mm) |

|

| |

Optional |

|

|

| |

4 | ¹⁄₈" | |||

Right Side (ST) | ||||

(105 mm) | ||||

| ||||

Figure 9

Step 3. Remove the nailing flanges from the lower control compartment and install in place with three (3) screws each. Align with the three holes on each side of the appliance (refer to Figure 5 ).

Install the hood on all units. Position the hood in the open area above the appliance door. Insert the tabs, on each end of the hood, into the bracket at each end. Bend the two tabs over to secure.

Step 4. Position appliance into prepared fram- ing, secure with 6d nails at the nailing flange along each side.

Step 5. Connecting Gas Line – Make gas line connections. All codes require a

Figure 10

Control

Valve

Lower Control

Compartment Door

Figure 11

The gas control valve is located in the lower control compartment. To access the valve open the lower control compartment door (Figure 11 ).

The control valve has a ³⁄₈" NPT thread inlet port and is fitted with two elbows and a nipple to provide the necessary offset. Plan your connections accordingly.

Secure all joints tightly using appropriate tools and sealing compounds (ensure propane resis- tant compounds are used in propane applica- tions). Turn on gas supply and test for gas leaks using a soapy water solution. Never use an open flame to check for leaks.

A. Mix a 50% dish soap, 50% water solution.

B. Light the appliance (refer to safety and lighting instructions on page 15).

C. Brush all joints and connections with the soapy water solution to check for leaks. If bubbles are formed, or gas odor is detected, turn the gas control knob to the “OFF” position. Either tighten or refasten the leaking connec- tion and retest as described above.

D. When the gas lines are tested and leak free, observe the individual tongues of flame on the burner. Make sure all ports are open and pro- ducing flame evenly across the burner. If any ports are blocked, or partially blocked, clean out the ports.

An external regulator must be used on all pro- pane (L.P.G.) heaters, in addition to the regula- tor fitted to the heater, to reduce the supply tank pressure to 13" w.c. (maximum).

WARNING: CONNECTING DIRECTLY TO AN UNREGULATED PROPANE TANK CAN CAUSE AN EXPLOSION.

Step 6. Wiring – The wiring diagram is de- tailed in Figure 12. Refer to Figure 13 to field wire optional wall switch. All electrical wiring must be in accordance with local codes or, in the absence of local codes the latest edition of the National Electrical Code, ANSI/NFPA 70. The heater must be electrically grounded.

8

NOTE: DIAGRAMS & ILLUSTRATION NOT TO SCALE.