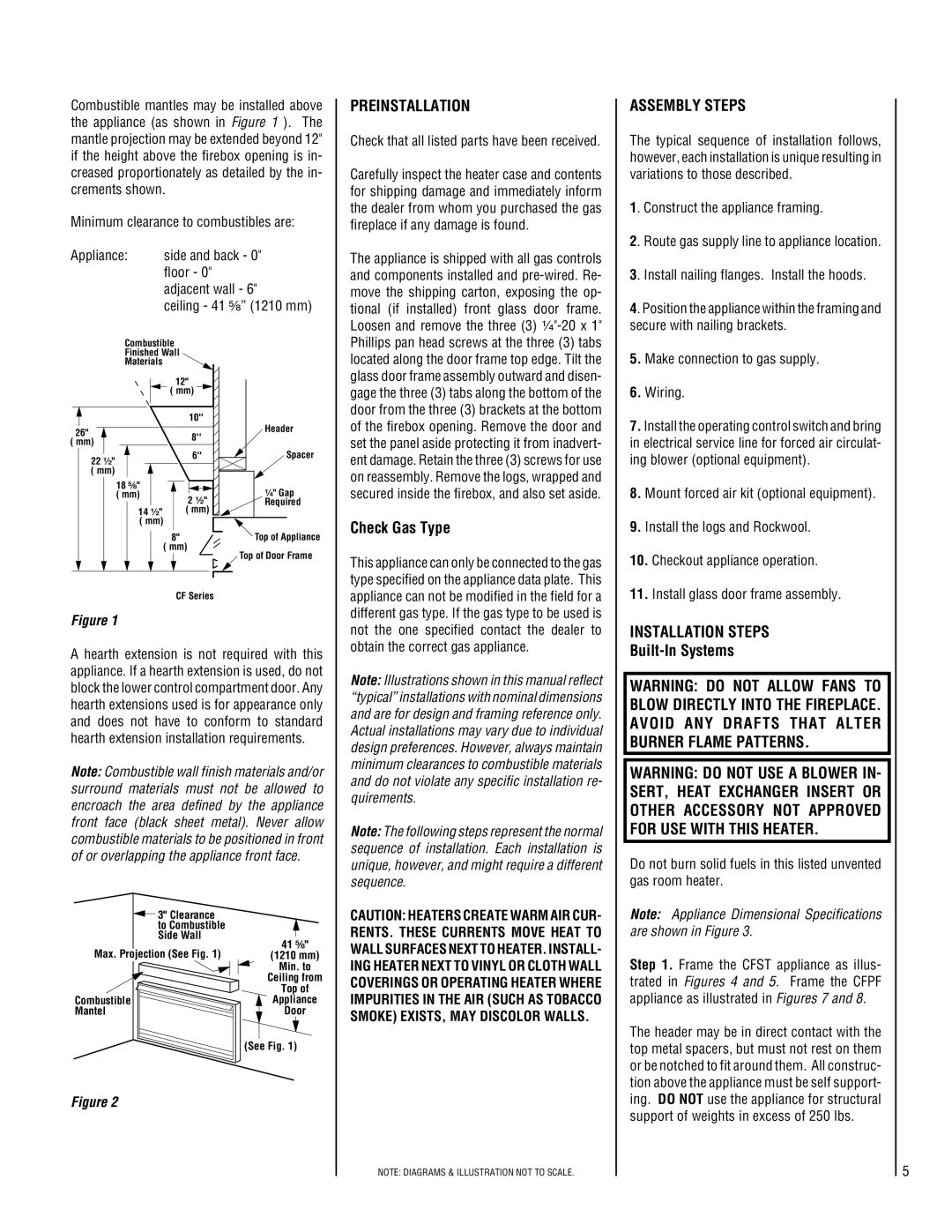

Combustible mantles may be installed above the appliance (as shown in Figure 1 ). The mantle projection may be extended beyond 12" if the height above the firebox opening is in- creased proportionately as detailed by the in- crements shown.

Minimum clearance to combustibles are:

Appliance: | side and back - 0" |

| floor - 0" |

| adjacent wall - 6" |

| ceiling - 41 ⁵⁄₈” (1210 mm) |

Combustible |

| ||

Finished Wall |

| ||

Materials |

|

| |

| 12" |

| |

| ( mm) |

| |

| 10'' | Header | |

26" | 8'' | ||

| |||

( mm) |

| ||

|

| ||

22 ¹⁄₂" | 6'' | Spacer | |

|

| ||

( mm) |

|

| |

18 ⁵⁄₈" |

| ¹⁄₄" Gap | |

( mm) | 2 ¹⁄₂" | ||

| Required | ||

14 ¹⁄₂" | ( mm) |

| |

( mm) |

|

| |

8" | Top of Appliance |

( mm) | Top of Door Frame |

| |

CF Series |

|

Figure 1

A hearth extension is not required with this appliance. If a hearth extension is used, do not block the lower control compartment door. Any hearth extensions used is for appearance only and does not have to conform to standard hearth extension installation requirements.

Note: Combustible wall finish materials and/or surround materials must not be allowed to encroach the area defined by the appliance front face (black sheet metal). Never allow combustible materials to be positioned in front of or overlapping the appliance front face.

![]() 3" Clearance

3" Clearance

to Combustible

Side Wall

Max. Projection (See Fig. 1) | 41 ⁵⁄₈" |

(1210 mm) | |

| Min. to |

| Ceiling from |

| Top of |

Combustible | Appliance |

Mantel | Door |

| (See Fig. 1) |

Figure 2

PREINSTALLATION

Check that all listed parts have been received.

Carefully inspect the heater case and contents for shipping damage and immediately inform the dealer from whom you purchased the gas fireplace if any damage is found.

The appliance is shipped with all gas controls and components installed and

Check Gas Type

This appliance can only be connected to the gas type specified on the appliance data plate. This appliance can not be modified in the field for a different gas type. If the gas type to be used is not the one specified contact the dealer to obtain the correct gas appliance.

Note: Illustrations shown in this manual reflect “typical” installations with nominal dimensions and are for design and framing reference only. Actual installations may vary due to individual design preferences. However, always maintain minimum clearances to combustible materials and do not violate any specific installation re- quirements.

Note: The following steps represent the normal sequence of installation. Each installation is unique, however, and might require a different sequence.

CAUTION: HEATERS CREATE WARM AIR CUR- RENTS. THESE CURRENTS MOVE HEAT TO WALL SURFACES NEXT TO HEATER. INSTALL- ING HEATER NEXT TO VINYL OR CLOTH WALL COVERINGS OR OPERATING HEATER WHERE IMPURITIES IN THE AIR (SUCH AS TOBACCO SMOKE) EXISTS, MAY DISCOLOR WALLS.

NOTE: DIAGRAMS & ILLUSTRATION NOT TO SCALE.

ASSEMBLY STEPS

The typical sequence of installation follows, however, each installation is unique resulting in variations to those described.

1. Construct the appliance framing.

2. Route gas supply line to appliance location.

3. Install nailing flanges. Install the hoods.

4. Position the appliance within the framing and secure with nailing brackets.

5.Make connection to gas supply.

6.Wiring.

7.Install the operating control switch and bring in electrical service line for forced air circulat- ing blower (optional equipment).

8.Mount forced air kit (optional equipment).

9.Install the logs and Rockwool.

10.Checkout appliance operation.

11.Install glass door frame assembly.

INSTALLATION STEPS

Built-In Systems

WARNING: DO NOT ALLOW FANS TO BLOW DIRECTLY INTO THE FIREPLACE. AVOID ANY DRAFTS THAT ALTER BURNER FLAME PATTERNS.

WARNING: DO NOT USE A BLOWER IN- SERT, HEAT EXCHANGER INSERT OR OTHER ACCESSORY NOT APPROVED FOR USE WITH THIS HEATER.

Do not burn solid fuels in this listed unvented gas room heater.

Note: Appliance Dimensional Specifications are shown in Figure 3.

Step 1. Frame the CFST appliance as illus- trated in Figures 4 and 5. Frame the CFPF appliance as illustrated in Figures 7 and 8.

The header may be in direct contact with the top metal spacers, but must not rest on them or be notched to fit around them. All construc- tion above the appliance must be self support- ing. DO NOT use the appliance for structural support of weights in excess of 250 lbs.

5