Portable Oxygen Monitor | Service Manual | |

|

|

|

investigation should be made until the discrepancy in readings is resolved. The troubleshooting section of this manual may provide additional assistance in locating the problem.

Note: The MSDS on this material is located in the Appendix. It is also available upon request through the Teledyne Environmental, Health and Safety Coordinator. Contact at

(626)

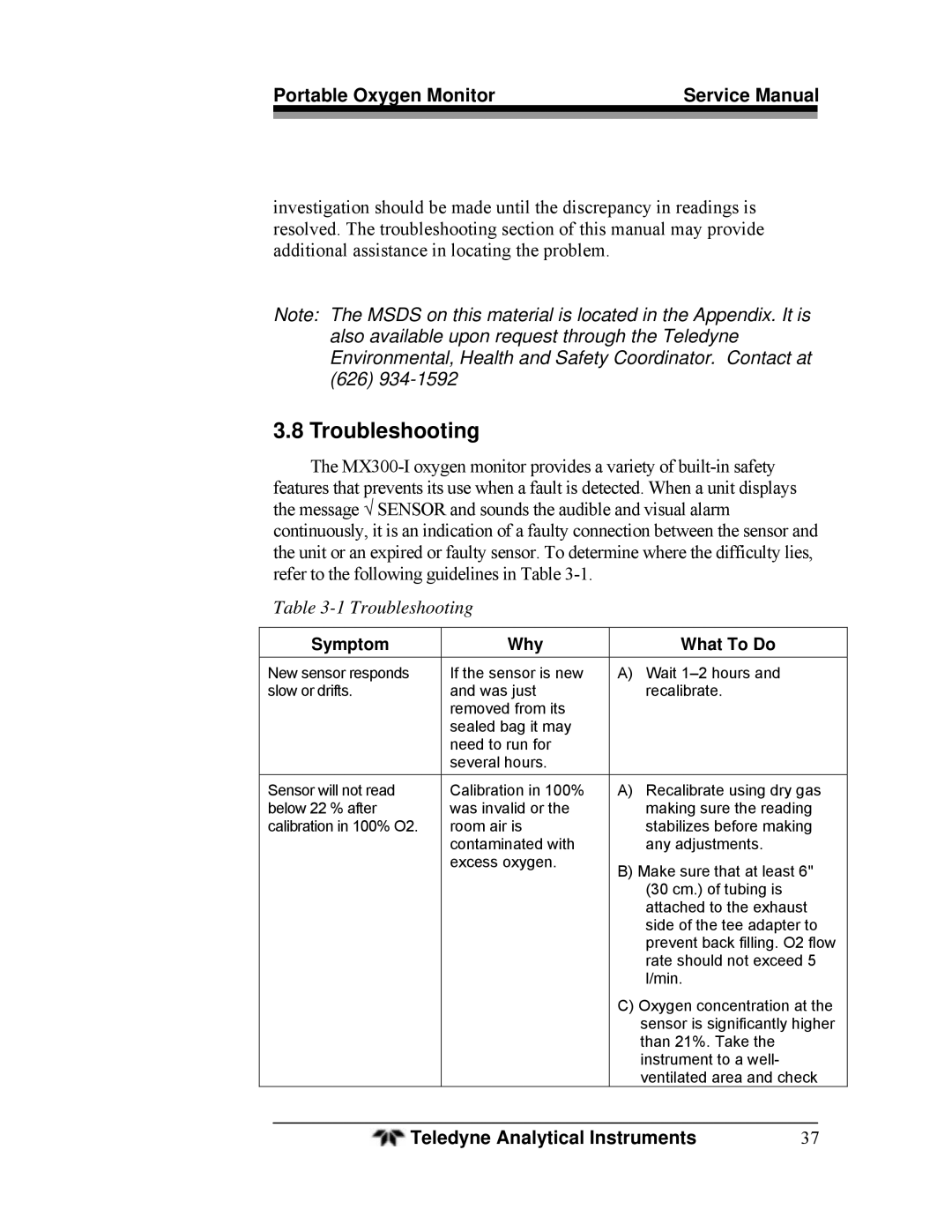

3.8Troubleshooting

The

Table 3-1 Troubleshooting

Symptom | Why | What To Do |

New sensor responds | If the sensor is new | A) Wait |

slow or drifts. | and was just | recalibrate. |

| removed from its |

|

| sealed bag it may |

|

| need to run for |

|

| several hours. |

|

Sensor will not read | Calibration in 100% | A) Recalibrate using dry gas |

below 22 % after | was invalid or the | making sure the reading |

calibration in 100% O2. | room air is | stabilizes before making |

| contaminated with | any adjustments. |

| excess oxygen. | B) Make sure that at least 6" |

|

| |

|

| (30 cm.) of tubing is |

|

| attached to the exhaust |

|

| side of the tee adapter to |

|

| prevent back filling. O2 flow |

|

| rate should not exceed 5 |

|

| l/min. |

|

| C) Oxygen concentration at the |

|

| sensor is significantly higher |

|

| than 21%. Take the |

|

| instrument to a well- |

|

| ventilated area and check |

Teledyne Analytical Instruments | 37 |