FDP2 Advanced Operation |

|

| FDP2 Group Control | FDP2 Duty/Standby Operation |

| ||

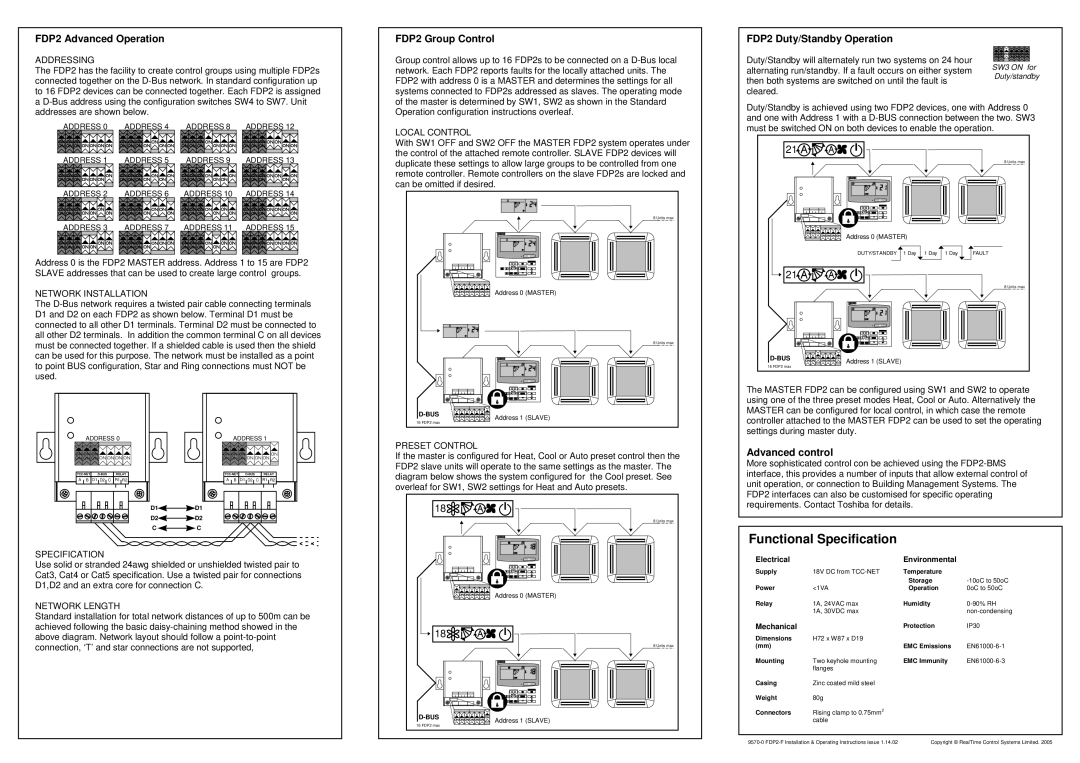

ADDRESSING |

|

|

| Group control allows up to 16 FDP2s to be connected on a | Duty/Standby will alternately run two systems on 24 hour | SW3 ON for | |

The FDP2 has the facility to create control groups using multiple FDP2s | network. Each FDP2 reports faults for the locally attached units. The | alternating run/standby. If a fault occurs on either system | |||||

Duty/standby | |||||||

connected together on the | FDP2 with address 0 is a MASTER and determines the settings for all | then both systems are switched on until the fault is | |||||

| |||||||

to 16 FDP2 devices can be connected together. Each FDP2 is assigned | systems connected to FDP2s addressed as slaves. The operating mode | cleared. |

| ||||

a | of the master is determined by SW1, SW2 as shown in the Standard | Duty/Standby is achieved using two FDP2 devices, one with Address 0 | |||||

addresses are shown below. |

|

| Operation configuration instructions overleaf. | ||||

|

| and one with Address 1 with a | |||||

ADDRESS 0 | ADDRESS 4 | ADDRESS 8 | ADDRESS 12 |

| |||

LOCAL CONTROL | must be switched ON on both devices to enable the operation. | ||||||

|

|

|

|

|

| ||

|

|

|

| With SW1 OFF and SW2 OFF the MASTER FDP2 system operates under | 21 |

| |

|

|

|

| the control of the attached remote controller. SLAVE FDP2 devices will |

| ||

ADDRESS 1 | ADDRESS 5 | ADDRESS 9 | ADDRESS 13 |

|

| ||

duplicate these settings to allow large groups to be controlled from one |

| 8 Units max | |||||

|

|

|

|

|

| ||

|

|

|

| remote controller. Remote controllers on the slave FDP2s are locked and |

|

| |

|

|

|

| can be omitted if desired. |

|

| |

ADDRESS 2 | ADDRESS 6 | ADDRESS 10 | ADDRESS 14 |

|

|

| |

8 Units max |

ADDRESS 3 ADDRESS 7 ADDRESS 11 ADDRESS 15 |

|

| Address 0 (MASTER) |

| DUTY/STANDBY 1 Day 1 Day 1 Day FAULT |

Address 0 is the FDP2 MASTER address. Address 1 to 15 are FDP2 |

|

SLAVE addresses that can be used to create large control groups. | 21 |

8 Units max

NETWORK INSTALLATION | Address 0 (MASTER) |

| |

The |

|

| |

D1 and D2 on each FDP2 as shown below. Terminal D1 must be |

|

| |

connected to all other D1 terminals. Terminal D2 must be connected to |

|

| |

all other D2 terminals. In addition the common terminal C on all devices |

|

| |

must be connected together. If a shielded cable is used then the shield | 8 Units max |

| |

|

| ||

can be used for this purpose. The network must be installed as a point | Address 1 (SLAVE) | ||

to point BUS configuration, Star and Ring connections must NOT be | 16 FDP2 max | ||

| |||

used. |

|

|

|

|

|

|

|

|

|

|

| The MASTER FDP2 can be configured using SW1 and SW2 to operate | |||

|

|

|

|

|

|

|

|

| using one of the three preset modes Heat, Cool or Auto. Alternatively the | |||

|

|

|

|

|

| Address 1 (SLAVE) |

| MASTER can be configured for local control, in which case the remote | ||||

|

|

|

|

|

|

| controller attached to the MASTER FDP2 can be used to set the operating | |||||

|

|

|

|

|

| 16 FDP2 max |

| |||||

|

|

|

|

|

|

|

| |||||

ADDRESS 0 | ADDRESS 1 |

|

|

| settings during master duty. |

|

| |||||

PRESET CONTROL |

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

| Advanced control |

|

| ||

|

|

|

|

|

| If the master is configured for Heat, Cool or Auto preset control then the |

|

| ||||

|

|

|

|

|

| More sophisticated control con be achieved using the | ||||||

|

|

|

|

|

| FDP2 slave units will operate to the same settings as the master. The | ||||||

|

|

|

|

|

| interface, this provides a number of inputs that allow external control of | ||||||

RELAY | RELAY | diagram below shows the system configured for | the Cool preset. See | |||||||||

A B | D1 D2 | C R1 R2 | A B | D1 D2 | C R1 R2 | unit operation, or connection to Building Management Systems. The | ||||||

|

|

|

|

|

| overleaf for SW1, SW2 settings for Heat and Auto presets. | ||||||

|

|

|

|

|

| FDP2 interfaces can also be customised for specific operating | ||||||

|

|

|

|

|

|

|

|

| ||||

|

| D1 | D1 |

|

| 18 |

|

| requirements. Contact Toshiba for details. |

| ||

|

|

|

|

|

|

|

|

|

| |||

|

| D2 | D2 |

|

|

|

| 8 Units max |

|

|

|

|

|

| C | C |

|

|

|

|

| Functional Specification |

|

| |

|

|

|

|

|

|

|

|

|

|

| ||

SPECIFICATION |

|

|

|

|

|

|

| Electrical |

| Environmental |

| |

Use solid or stranded 24awg shielded or unshielded twisted pair to |

|

|

|

|

| |||||||

|

|

| Supply | 18V DC from | Temperature |

| ||||||

Cat3, Cat4 or Cat5 specification. Use a twisted pair for connections |

|

|

|

| ||||||||

|

|

|

|

| Storage | |||||||

D1,D2 and an extra core for connection C. |

|

|

|

|

|

|

| |||||

|

|

|

|

| Power | <1VA | Operation | 0oC to 50oC | ||||

|

|

|

|

|

|

| Address 0 (MASTER) |

|

|

|

|

|

NETWORK LENGTH |

|

|

|

|

|

| Relay | 1A, 24VAC max | Humidity | |||

Standard installation for total network distances of up to 500m can be |

|

|

|

| 1A, 30VDC max |

| ||||||

|

|

|

|

|

|

| ||||||

achieved following the basic | 18 |

|

| Mechanical |

| Protection | IP30 | |||||

above diagram. Network layout should follow a |

|

| Dimensions | H72 x W87 x D19 |

|

| ||||||

|

|

| EMC Emissions | |||||||||

connection, ‘T’ and star connections are not supported, |

|

|

| 8 Units max | (mm) |

| ||||||

|

|

|

|

|

|

|

|

| Mounting | Two keyhole mounting | EMC Immunity | |

|

|

|

|

|

|

|

|

|

| flanges |

|

|

|

|

|

|

|

|

|

|

| Casing | Zinc coated mild steel |

|

|

|

|

|

|

|

|

|

|

| Weight | 80g |

|

|

|

|

|

|

|

|

|

| Connectors | Rising clamp to 0.75mm2 |

|

| |

|

|

|

|

|

| Address 1 (SLAVE) |

|

| cable |

|

| |

|

|

|

|

|

| 16 FDP2 max |

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

| |

Copyright © RealTime Control Systems Limited. 2005 |