Installer’s Guide

Q

▲! CAUTION

Replace and/ or tighten all plugs removed or loosened when adjusting gas pressure. Leak check the fittings before placing the furnace into regular service.

Failure to follow this warning could result in fire, ex- plosion, or property damage.

NOTE:

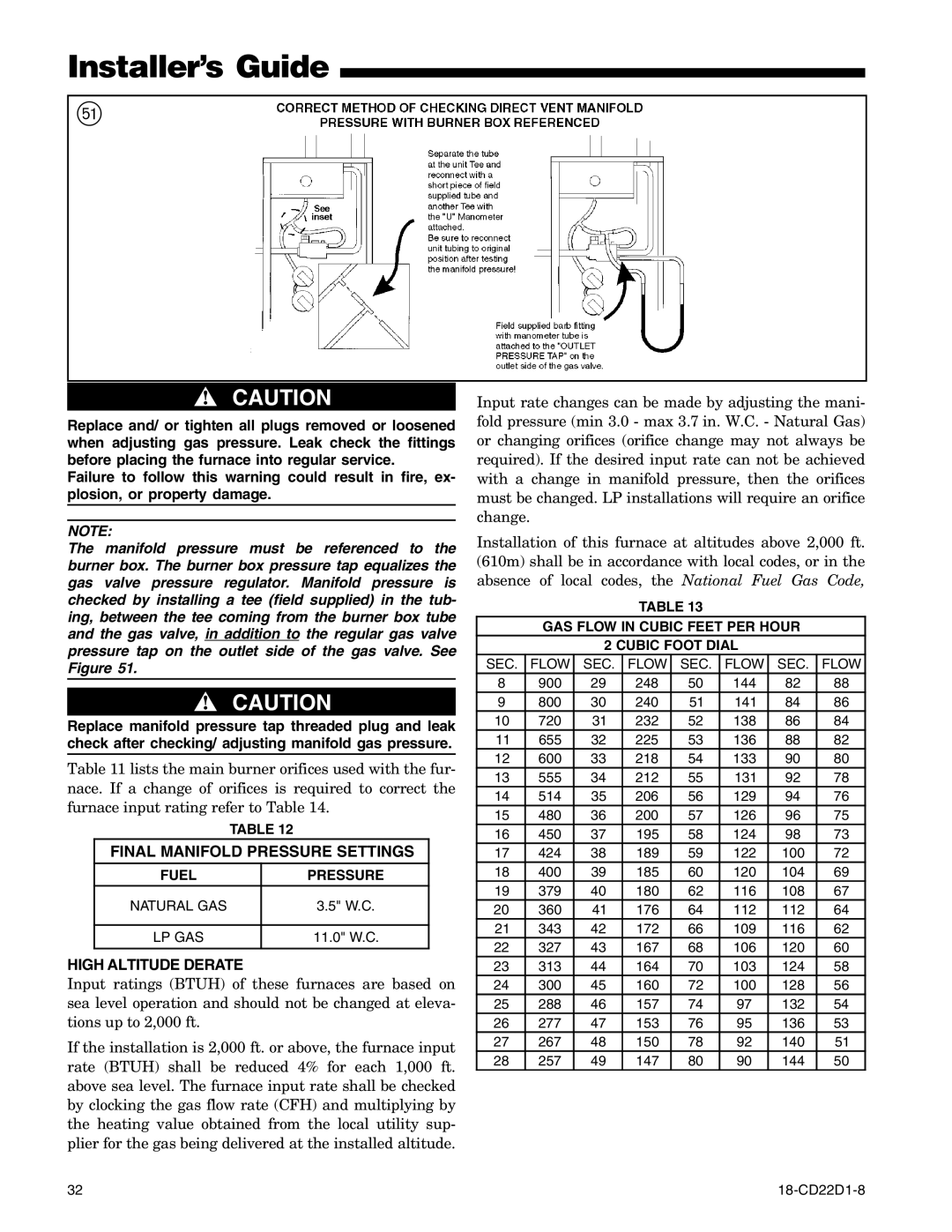

The manifold pressure must be referenced to the burner box. The burner box pressure tap equalizes the gas valve pressure regulator. Manifold pressure is checked by installing a tee (field supplied) in the tub- ing, between the tee coming from the burner box tube and the gas valve, in addition to the regular gas valve pressure tap on the outlet side of the gas valve. See Figure 51.

▲! CAUTION

Replace manifold pressure tap threaded plug and leak check after checking/ adjusting manifold gas pressure.

Table 11 lists the main burner orifices used with the fur- nace. If a change of orifices is required to correct the furnace input rating refer to Table 14.

TABLE 12

FINAL MANIFOLD PRESSURE SETTINGS

FUEL | PRESSURE |

|

|

NATURAL GAS | 3.5" W.C. |

|

|

LP GAS | 11.0" W.C. |

|

|

HIGH ALTITUDE DERATE

Input ratings (BTUH) of these furnaces are based on sea level operation and should not be changed at eleva- tions up to 2,000 ft.

If the installation is 2,000 ft. or above, the furnace input rate (BTUH) shall be reduced 4% for each 1,000 ft. above sea level. The furnace input rate shall be checked by clocking the gas flow rate (CFH) and multiplying by the heating value obtained from the local utility sup- plier for the gas being delivered at the installed altitude.

Input rate changes can be made by adjusting the mani- fold pressure (min 3.0 - max 3.7 in. W.C. - Natural Gas) or changing orifices (orifice change may not always be required). If the desired input rate can not be achieved with a change in manifold pressure, then the orifices must be changed. LP installations will require an orifice change.

Installation of this furnace at altitudes above 2,000 ft. (610m) shall be in accordance with local codes, or in the absence of local codes, the National Fuel Gas Code,

TABLE 13

GAS FLOW IN CUBIC FEET PER HOUR

2 CUBIC FOOT DIAL

SEC. | FLOW | SEC. | FLOW | SEC. | FLOW | SEC. | FLOW |

8 | 900 | 29 | 248 | 50 | 144 | 82 | 88 |

9 | 800 | 30 | 240 | 51 | 141 | 84 | 86 |

10 | 720 | 31 | 232 | 52 | 138 | 86 | 84 |

11 | 655 | 32 | 225 | 53 | 136 | 88 | 82 |

12 | 600 | 33 | 218 | 54 | 133 | 90 | 80 |

13 | 555 | 34 | 212 | 55 | 131 | 92 | 78 |

14 | 514 | 35 | 206 | 56 | 129 | 94 | 76 |

15 | 480 | 36 | 200 | 57 | 126 | 96 | 75 |

16 | 450 | 37 | 195 | 58 | 124 | 98 | 73 |

17 | 424 | 38 | 189 | 59 | 122 | 100 | 72 |

18 | 400 | 39 | 185 | 60 | 120 | 104 | 69 |

19 | 379 | 40 | 180 | 62 | 116 | 108 | 67 |

20 | 360 | 41 | 176 | 64 | 112 | 112 | 64 |

21 | 343 | 42 | 172 | 66 | 109 | 116 | 62 |

22 | 327 | 43 | 167 | 68 | 106 | 120 | 60 |

23 | 313 | 44 | 164 | 70 | 103 | 124 | 58 |

24 | 300 | 45 | 160 | 72 | 100 | 128 | 56 |

25 | 288 | 46 | 157 | 74 | 97 | 132 | 54 |

26 | 277 | 47 | 153 | 76 | 95 | 136 | 53 |

27 | 267 | 48 | 150 | 78 | 92 | 140 | 51 |

28 | 257 | 49 | 147 | 80 | 90 | 144 | 50 |

32 |