(2)HY-5G, HY-5G specifications

Unified Brands HY-5G (2) HY-5G represents a significant leap in commercial kitchen equipment, specifically designed to enhance the performance of food preparation in various culinary environments. With its robust build and innovative features, this product offers chefs and restaurant owners a unique blend of efficiency, versatility, and reliability.One of the main features of the HY-5G is its state-of-the-art control system, which allows for precise management of cooking processes. This system utilizes advanced digital technology, enabling users to set and monitor cooking times and temperatures with unparalleled accuracy. This level of control not only ensures consistent food quality but also simplifies the workflow in busy kitchens.

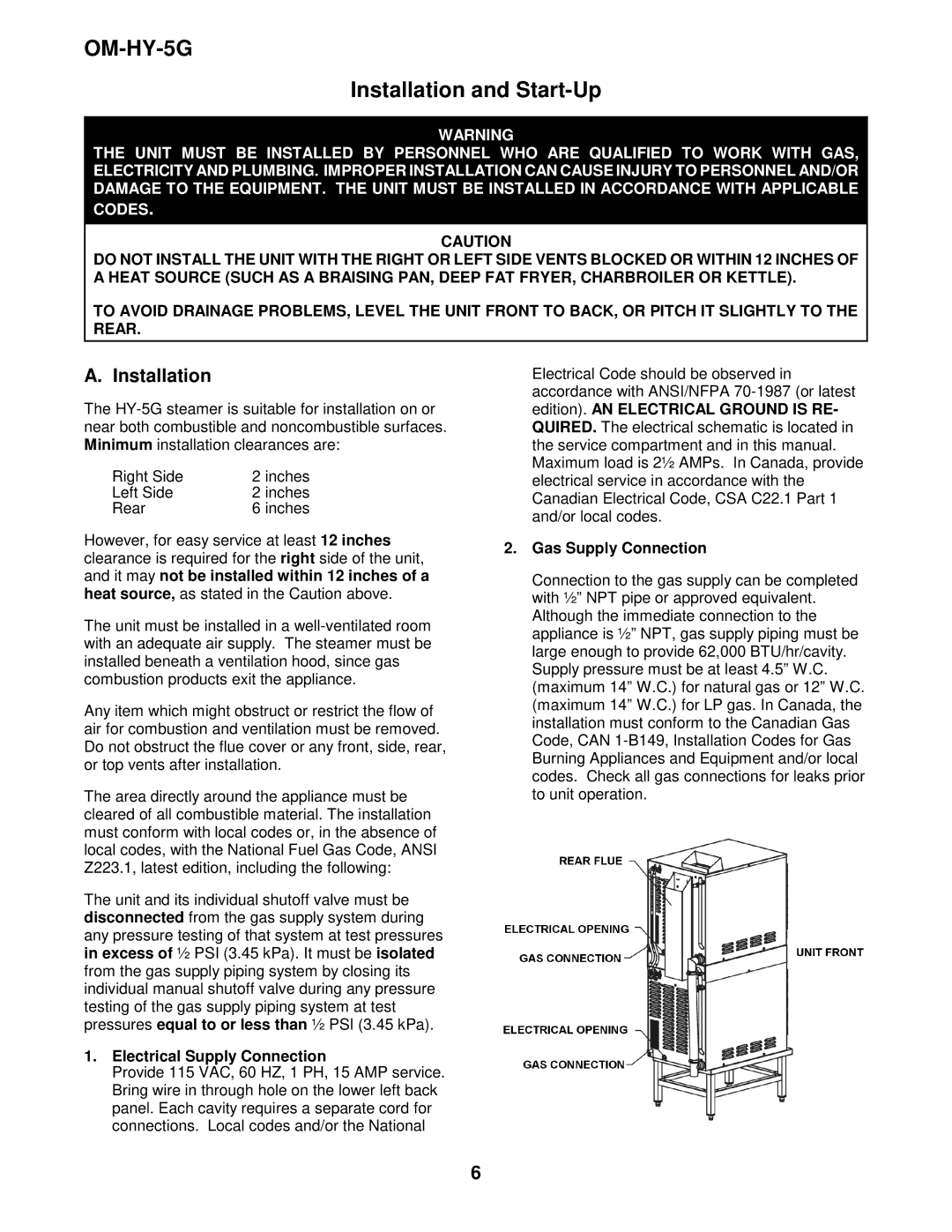

The design of the HY-5G is another standout characteristic. Built with high-quality stainless steel, it is both durable and easy to clean, a crucial aspect in the fast-paced environment of commercial kitchens. The sleek design not only contributes to its functionality but also adds an aesthetic appeal that fits seamlessly into modern kitchen designs.

Another notable technology integrated into the HY-5G is the energy-efficient heating system. This innovation allows the unit to reach optimal cooking temperatures quickly, reducing energy consumption and overall operating costs. Consequently, restaurants can enjoy reduced energy bills while maintaining high productivity levels.

Moreover, the HY-5G is equipped with safety features that ensure a secure cooking environment. Automatic shut-off mechanisms and temperature sensors contribute to minimizing the risk of overheating and other potential hazards, making it a safe choice for any kitchen staff.

Furthermore, the versatility of the HY-5G allows it to handle a variety of cooking methods, including frying, grilling, and steaming. This adaptability makes it suitable for diverse culinary applications, from casual dining to high-end gastronomy.

In conclusion, Unified Brands HY-5G (2) HY-5G stands out as a premier solution for commercial kitchens, combining modern technology with practical features. Its focus on efficiency, safety, and versatility ensures that food preparation can be executed smoothly, allowing chefs to focus on delivering high-quality meals. As the demands of the culinary world continue to evolve, the HY-5G remains a reliable ally in any kitchen, helping to elevate the overall dining experience.