Defiant 1610

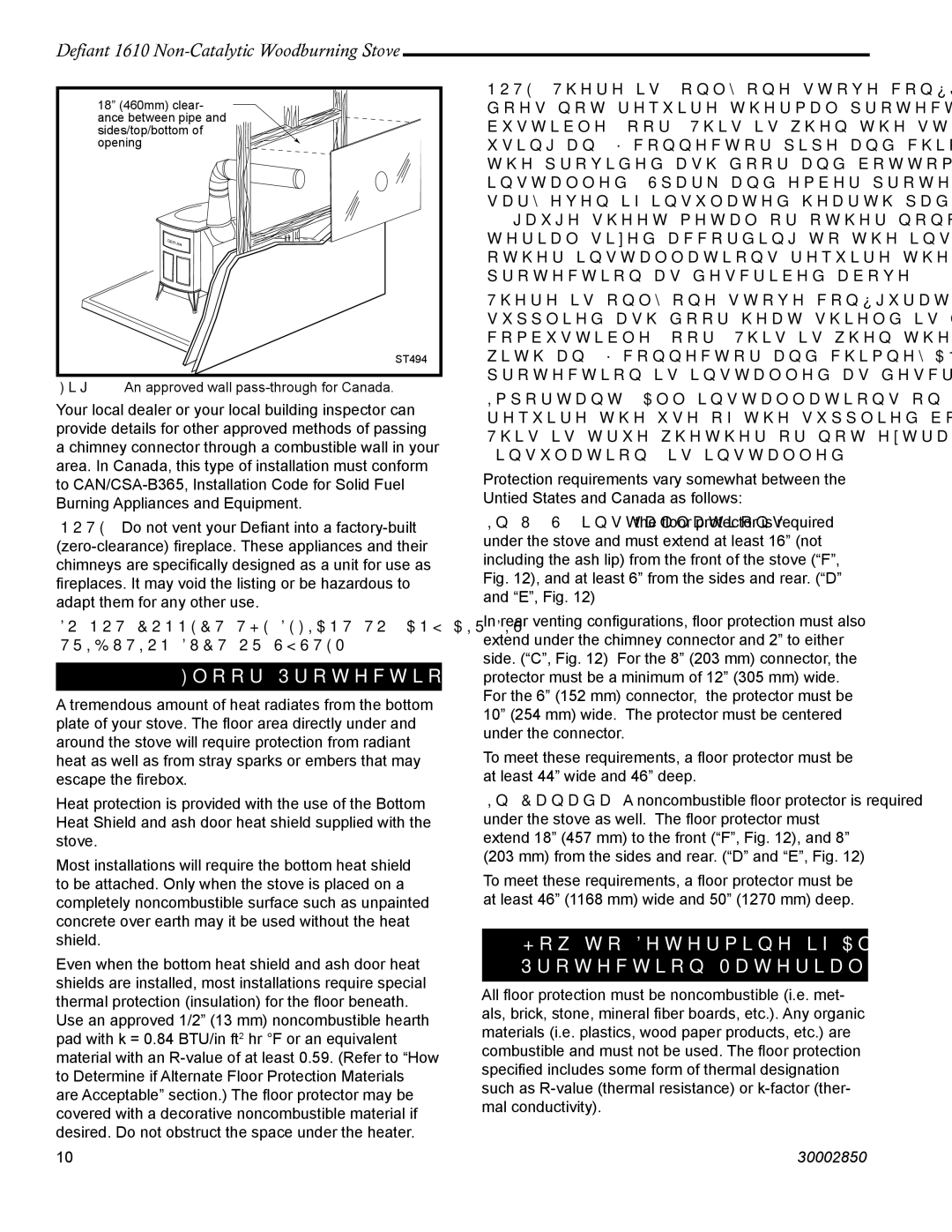

18” (460mm) clear- ance between pipe and sides/top/bottom of opening

T

DEFIAN

ST494

Fig. 11 An approved wall pass-through for Canada.

Your local dealer or your local building inspector can provide details for other approved methods of passing a chimney connector through a combustible wall in your area. In Canada, this type of installation must conform to

NOTE: Do not vent your Defiant into a

DO NOT CONNECT THE DEFIANT TO ANY AIR DIS- TRIBUTION DUCT OR SYSTEM.

Floor Protection

A tremendous amount of heat radiates from the bottom plate of your stove. The floor area directly under and around the stove will require protection from radiant heat as well as from stray sparks or embers that may escape the firebox.

Heat protection is provided with the use of the Bottom Heat Shield and ash door heat shield supplied with the stove.

Most installations will require the bottom heat shield to be attached. Only when the stove is placed on a completely noncombustible surface such as unpainted concrete over earth may it be used without the heat shield.

Even when the bottom heat shield and ash door heat shields are installed, most installations require special thermal protection (insulation) for the floor beneath.

Use an approved 1/2” (13 mm) noncombustible hearth pad with k = 0.84 BTU/in ft2 hr °F or an equivalent material with an

NOTE: There is only one stove configuration that does not require thermal protection for a com- bustible floor. This is when the stove is installed using an 8” connector pipe and chimney AND when the provided ash door and bottom heat shield are installed. Spark and ember protection is still neces- sary even if insulated hearth pad is not used. Use 24 gauge sheet metal or other noncombustible ma- terial sized according to the instructions below. All other installations require the use of thermal floor protection as described above.

There is only one stove configuration where the supplied ash door heat shield is not required over a combustible floor. This is when the stove is vented with an 8” connector and chimney AND thermal protection is installed as described above.

Important: All installations on a combustible floor require the use of the supplied bottom heat shield. This is true whether or not extra thermal protection (insulation) is installed.

Protection requirements vary somewhat between the Untied States and Canada as follows:

In U. S. installations the floor protector is required under the stove and must extend at least 16” (not including the ash lip) from the front of the stove (“F”, Fig. 12), and at least 6” from the sides and rear. (“D” and “E”, Fig. 12)

In rear venting configurations, floor protection must also extend under the chimney connector and 2” to either side. (“C”, Fig. 12) For the 8” (203 mm) connector, the protector must be a minimum of 12” (305 mm) wide. For the 6” (152 mm) connector, the protector must be 10” (254 mm) wide. The protector must be centered under the connector.

To meet these requirements, a floor protector must be at least 44” wide and 46” deep.

In Canada: A noncombustible floor protector is required under the stove as well. The floor protector must extend 18” (457 mm) to the front (“F”, Fig. 12), and 8” (203 mm) from the sides and rear. (“D” and “E”, Fig. 12)

To meet these requirements, a floor protector must be at least 46” (1168 mm) wide and 50” (1270 mm) deep.

How to Determine if Alternate Floor Protection Materials are Acceptable

All floor protection must be noncombustible (i.e. met- als, brick, stone, mineral fiber boards, etc.). Any organic materials (i.e. plastics, wood paper products, etc.) are combustible and must not be used. The floor protection specified includes some form of thermal designation such as

10 | 30002850 |