Defiant 1610

clothes, furniture, newspapers, firewood, etc. Keep- ing those clearance areas empty assures that nearby surfaces and objects will not overheat.

Safe Ways to Reduce Clearances

Clearance requirements are established to meet every installation possibility, and they involve the combination of these variables:

•When the stove pipe has no listed heat shield mounted on it.

•When the wall has no heat shield mounted on it.

•When the wall has a heat shield mounted on it.

•When the wall and stove pipe have heat shields. In general, the greatest clearance is required when you place a stove and its connector near a wall with no heat shield.

For example, when the Defiant is installed parallel to the rear wall with 8” pipe and no connector shield is used, it must be at least 35” (889 mm) from the wall behind it and at least 23” (584 mm) from walls on either side. These dimensions are measured from the top edge of the stove to the combustible wall.

If the Defiant is installed in a corner and no shield is used, the corners of the stove top must be at least 25” (635 mm) from nearby walls when using 8” connector pipe.

Clearances may be reduced only by means approved by the regulatory authority, and in accordance with the clearances listed in this manual. Refer to Pages 10 - 13 for approved clearance reduction specifications.

NOTE: Clearance requirements differ for 8” and 6” con- nector pipe installation. A minimum ceiling height of 8 feet (2.4 m) is required for all installations of the Defiant NC.

NOTE: Installation of the Defiant is not permitted in alcoves.

Wall Shields

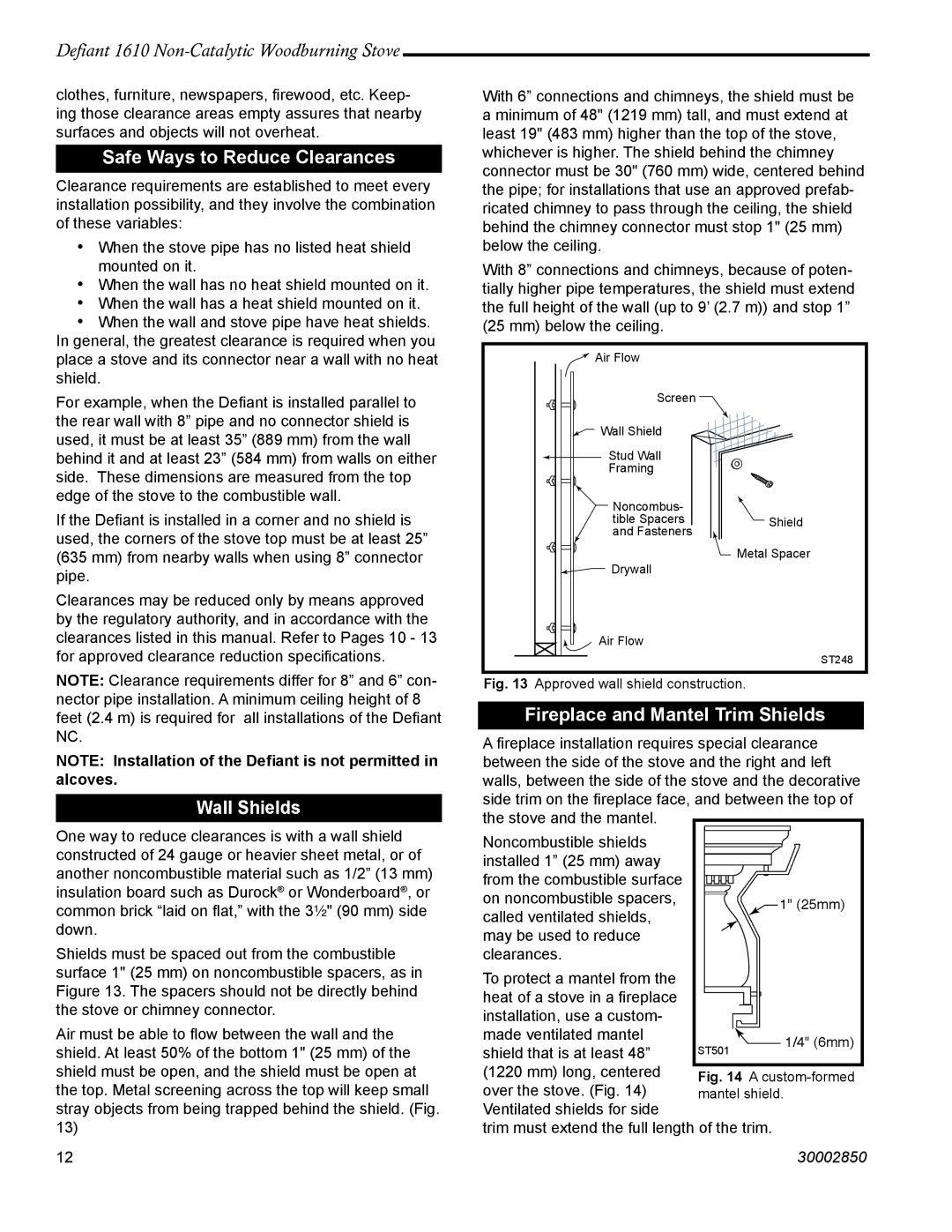

One way to reduce clearances is with a wall shield constructed of 24 gauge or heavier sheet metal, or of another noncombustible material such as 1/2” (13 mm) insulation board such as Durock® or Wonderboard®, or common brick “laid on flat,” with the 3¹⁄₂" (90 mm) side down.

Shields must be spaced out from the combustible surface 1" (25 mm) on noncombustible spacers, as in Figure 13. The spacers should not be directly behind the stove or chimney connector.

Air must be able to flow between the wall and the shield. At least 50% of the bottom 1" (25 mm) of the shield must be open, and the shield must be open at the top. Metal screening across the top will keep small stray objects from being trapped behind the shield. (Fig. 13)

With 6” connections and chimneys, the shield must be a minimum of 48" (1219 mm) tall, and must extend at least 19" (483 mm) higher than the top of the stove, whichever is higher. The shield behind the chimney connector must be 30" (760 mm) wide, centered behind the pipe; for installations that use an approved prefab- ricated chimney to pass through the ceiling, the shield behind the chimney connector must stop 1" (25 mm) below the ceiling.

With 8” connections and chimneys, because of poten- tially higher pipe temperatures, the shield must extend the full height of the wall (up to 9’ (2.7 m)) and stop 1” (25 mm) below the ceiling.

Air Flow |

|

Screen |

|

Wall Shield |

|

Stud Wall |

|

Framing |

|

Noncombus- |

|

tible Spacers | Shield |

and Fasteners |

|

| Metal Spacer |

Drywall |

|

Air Flow |

|

| ST248 |

Fig. 13 Approved wall shield construction.

Fireplace and Mantel Trim Shields

A fireplace installation requires special clearance between the side of the stove and the right and left walls, between the side of the stove and the decorative side trim on the fireplace face, and between the top of the stove and the mantel.

Noncombustible shields |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

installed 1” (25 mm) away |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

from the combustible surface |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

on noncombustible spacers, |

|

|

|

|

|

|

|

|

|

|

|

|

| 1" (25mm) | |||

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

called ventilated shields, |

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

may be used to reduce |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

clearances. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

To protect a mantel from the |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

heat of a stove in a fireplace |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

installation, use a custom- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

made ventilated mantel | ST501 |

|

|

|

|

| 1/4" (6mm) | ||||||||||

shield that is at least 48” |

|

|

|

|

| ||||||||||||

|

|

|

|

|

|

| |||||||||||

(1220 mm) long, centered | Fig. 14 A | ||||||||||||||||

over the stove. (Fig. 14) | |||||||||||||||||

mantel shield. | |||||||||||||||||

Ventilated shields for side

trim must extend the full length of the trim.

12 | 30002850 |