Chateau™ Direct Vent Gas Fireplace

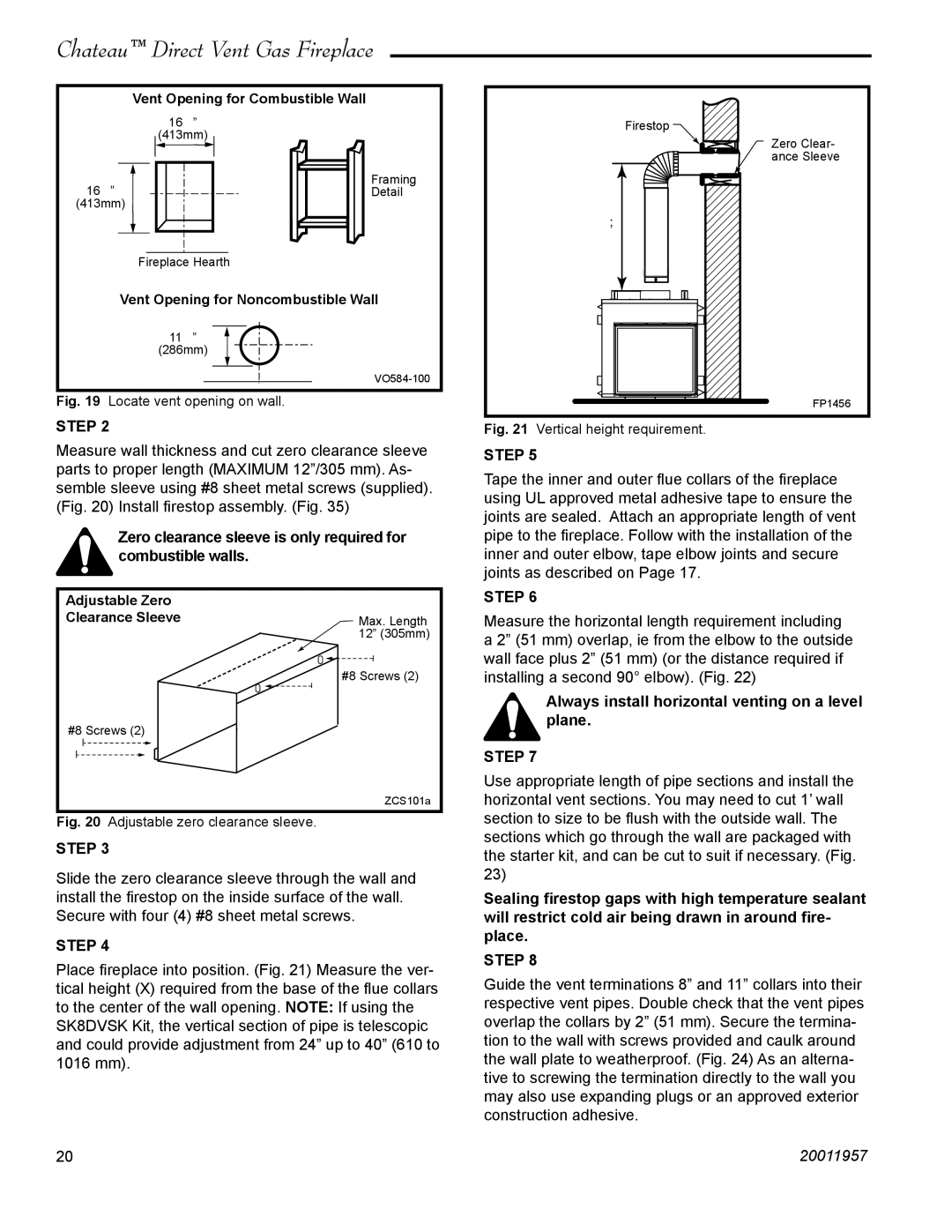

Vent Opening for Combustible Wall

16¹⁄₄”

(413mm)

16¹⁄₄” |

|

|

|

|

|

| Framing | |

|

|

|

| Detail | ||||

(413mm) |

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fireplace Hearth

Vent Opening for Noncombustible Wall

11¹⁄₄”

(286mm)

Fig. 19 Locate vent opening on wall.

STEP 2

Measure wall thickness and cut zero clearance sleeve parts to proper length (MAXIMUM 12”/305 mm). As- semble sleeve using #8 sheet metal screws (supplied). (Fig. 20) Install firestop assembly. (Fig. 35)

Zero clearance sleeve is only required for combustible walls.

Adjustable Zero |

|

Clearance Sleeve | Max. Length |

| 12” (305mm) |

| #8 Screws (2) |

#8 Screws (2) |

|

| ZCS101a |

Fig. 20 Adjustable zero clearance sleeve. |

|

STEP 3

Slide the zero clearance sleeve through the wall and install the firestop on the inside surface of the wall. Secure with four (4) #8 sheet metal screws.

STEP 4

Place fireplace into position. (Fig. 21) Measure the ver- tical height (X) required from the base of the flue collars to the center of the wall opening. NOTE: If using the SK8DVSK Kit, the vertical section of pipe is telescopic and could provide adjustment from 24” up to 40” (610 to 1016 mm).

Firestop

Zero Clear-

ance Sleeve

X

FP1456

Fig. 21 Vertical height requirement.

STEP 5

Tape the inner and outer flue collars of the fireplace using UL approved metal adhesive tape to ensure the joints are sealed. Attach an appropriate length of vent pipe to the fireplace. Follow with the installation of the inner and outer elbow, tape elbow joints and secure joints as described on Page 17.

STEP 6

Measure the horizontal length requirement including a 2” (51 mm) overlap, ie from the elbow to the outside wall face plus 2” (51 mm) (or the distance required if installing a second 90° elbow). (Fig. 22)

Always install horizontal venting on a level plane.

STEP 7

Use appropriate length of pipe sections and install the horizontal vent sections. You may need to cut 1’ wall section to size to be flush with the outside wall. The sections which go through the wall are packaged with the starter kit, and can be cut to suit if necessary. (Fig. 23)

Sealing firestop gaps with high temperature sealant will restrict cold air being drawn in around fire- place.

STEP 8

Guide the vent terminations 8” and 11” collars into their respective vent pipes. Double check that the vent pipes overlap the collars by 2” (51 mm). Secure the termina- tion to the wall with screws provided and caulk around the wall plate to weatherproof. (Fig. 24) As an alterna- tive to screwing the termination directly to the wall you may also use expanding plugs or an approved exterior construction adhesive.

20 | 20011957 |