Stardance Natural Vent Gas Heater

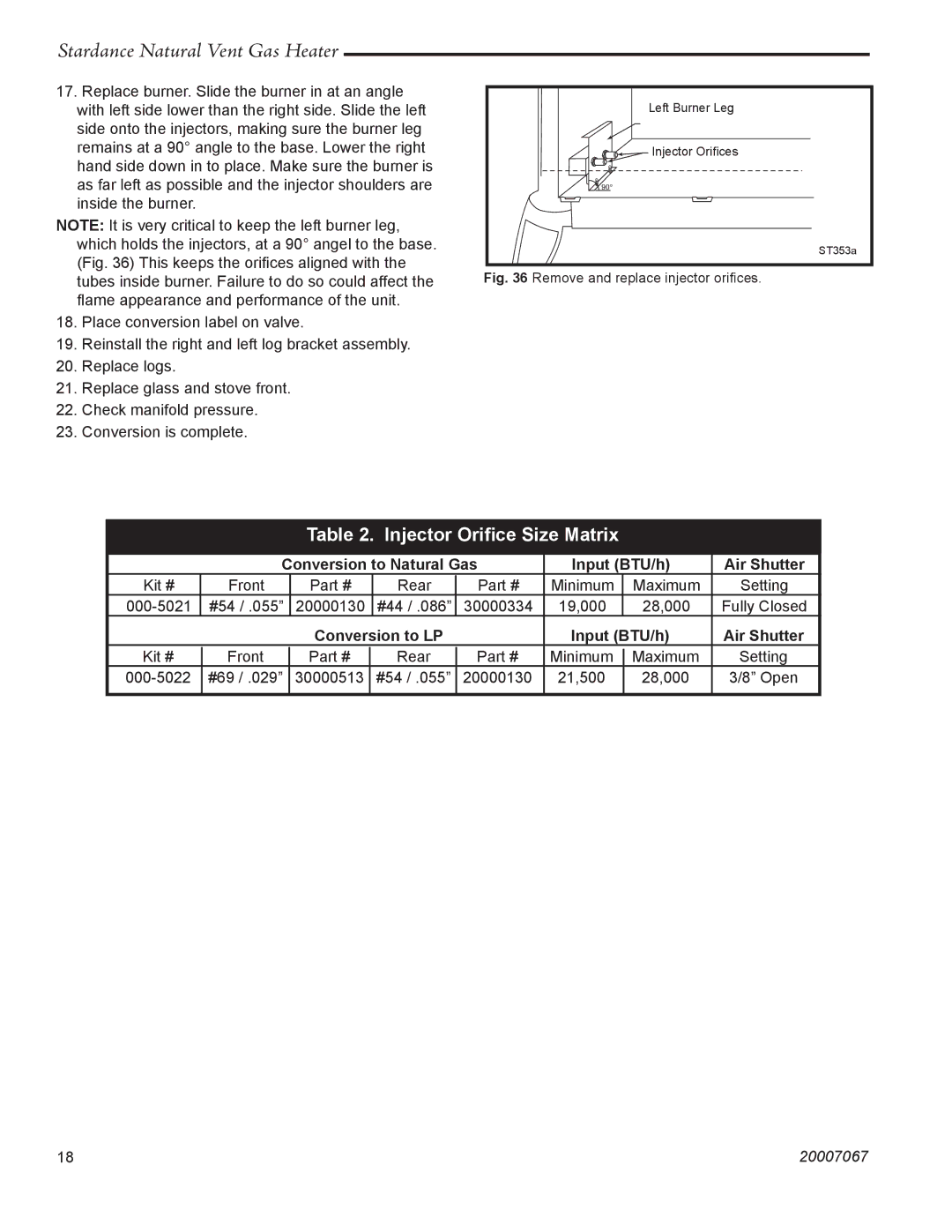

17.Replace burner. Slide the burner in at an angle with left side lower than the right side. Slide the left side onto the injectors, making sure the burner leg remains at a 90° angle to the base. Lower the right hand side down in to place. Make sure the burner is as far left as possible and the injector shoulders are inside the burner.

NOTE: It is very critical to keep the left burner leg, which holds the injectors, at a 90° angel to the base. (Fig. 36) This keeps the orifices aligned with the tubes inside burner. Failure to do so could affect the flame appearance and performance of the unit.

18.Place conversion label on valve.

19.Reinstall the right and left log bracket assembly.

20.Replace logs.

21.Replace glass and stove front.

22.Check manifold pressure.

23.Conversion is complete.

Left Burner Leg |

Injector Orifices |

90° |

ST353a

Fig. 36 Remove and replace injector orifices.

Table 2. Injector Orifice Size Matrix

|

| Conversion to Natural Gas | Input (BTU/h) | Air Shutter | ||||||||

Kit # |

| Front | Part # | Rear |

| Part # | Minimum |

| Maximum | Setting | ||

| #54 / .055” | 20000130 |

| #44 / .086” | 30000334 | 19,000 | 28,000 | Fully Closed | ||||

|

|

|

| Conversion to LP |

|

| Input (BTU/h) | Air Shutter | ||||

Kit # |

| Front |

| Part # |

| Rear |

| Part # | Minimum |

| Maximum | Setting |

|

|

|

|

| ||||||||

| #69 / .029” |

| 30000513 |

| #54 / .055” |

| 20000130 | 21,500 |

| 28,000 | 3/8” Open | |

|

|

|

|

|

|

|

|

|

|

|

|

|

1818 | 20007067 |