Stardance Natural Vent Gas Heater

Fuel Conversion Instructions

WARNING! This conversion kit shall be installed by a qualified service agency in accordance with the manufacturer’s instructions and all applicable codes and requirements of the authority having jurisdiction. If the information in these instruc- tions is not followed exactly, a fire, explosion

or production of carbon monoxide may result causing property damage, personal injury or loss of life. The qualified service agency is respon- sible for the proper installation of this kit. The installation is not proper and complete until the operation of the converted appliance is checked as specified in the manufacturer’s instructions supplied with the kit.

CAUTION: The gas supply shall be shut off prior to disconnecting the electrical power, before pro- ceeding with the conversion.

|

| OFF |

| I |

|

| H O | NO |

|

| TPILOJAD |

|

| Main |

|

| Gas Line |

| Gas Supply Inlet | |

|

| ST226 |

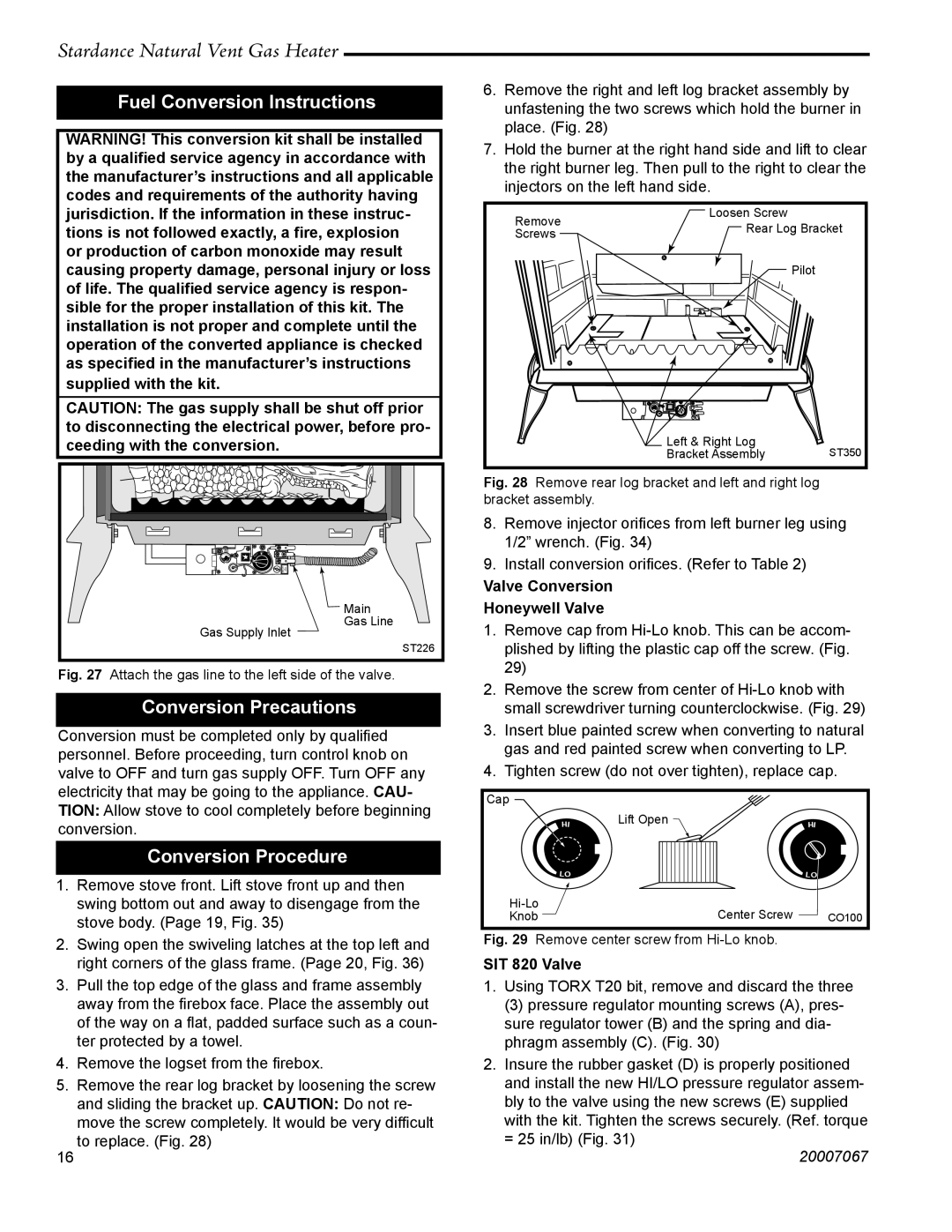

Fig. 27 | Attach the gas line to the left side of the valve. | |

Conversion Precautions

Conversion must be completed only by qualified personnel. Before proceeding, turn control knob on valve to OFF and turn gas supply OFF. Turn OFF any electricity that may be going to the appliance. CAU-

6.Remove the right and left log bracket assembly by unfastening the two screws which hold the burner in place. (Fig. 28)

7.Hold the burner at the right hand side and lift to clear the right burner leg. Then pull to the right to clear the injectors on the left hand side.

Remove | Loosen Screw |

| |

Rear Log Bracket | |||

Screws | |||

|

| ||

|

| Pilot | |

| Left & Right Log | ST350 | |

| Bracket Assembly | ||

Fig. 28 Remove rear log bracket and left and right log bracket assembly.

8.Remove injector orifices from left burner leg using 1/2” wrench. (Fig. 34)

9.Install conversion orifices. (Refer to Table 2)

Valve Conversion Honeywell Valve

1.Remove cap from

2.Remove the screw from center of

3.Insert blue painted screw when converting to natural gas and red painted screw when converting to LP.

4.Tighten screw (do not over tighten), replace cap.

TION: Allow stove to cool completely before beginning conversion.

Conversion Procedure

1. Remove stove front. Lift stove front up and then |

swing bottom out and away to disengage from the |

stove body. (Page 19, Fig. 35) |

Cap

HI

LO

Knob

Lift Open

HI

LO

Center Screw ![]() CO100

CO100

2. | Swing open the swiveling latches at the top left and |

| right corners of the glass frame. (Page 20, Fig. 36) |

3. | Pull the top edge of the glass and frame assembly |

| away from the firebox face. Place the assembly out |

| of the way on a flat, padded surface such as a coun- |

| ter protected by a towel. |

4. | Remove the logset from the firebox. |

5. | Remove the rear log bracket by loosening the screw |

| and sliding the bracket up. CAUTION: Do not re- |

| move the screw completely. It would be very difficult |

to replace. (Fig. 28)

1616

Fig. 29 Remove center screw from Hi-Lo knob.

SIT 820 Valve

1.Using TORX T20 bit, remove and discard the three

(3) pressure regulator mounting screws (A), pres- sure regulator tower (B) and the spring and dia- phragm assembly (C). (Fig. 30)

2.Insure the rubber gasket (D) is properly positioned and install the new HI/LO pressure regulator assem- bly to the valve using the new screws (E) supplied with the kit. Tighten the screws securely. (Ref. torque = 25 in/lb) (Fig. 31)

20007067