Optional Hose Position

As shipped, fluid inlet swivel fittings point to rear of the gun. If desired, use the following procedure to make the fluid inlet swivel fittings point downward.

NOTICE

To prevent

1.Follow Pressure Relief Procedure, page 22.

2.Disconnect air quick coupler (AC). Use hex nut driver to remove fluid manifold (AD).

AD | AC |

TI14463a

3.Disconnect signal cable.

4.Place a cap over the end of each hose. Disconnect fluid hoses from inlet swivels (AE). Remove plugs from optional inlets (AG).

AE

TI2417a

AE

AG

FIG. 10

Setup

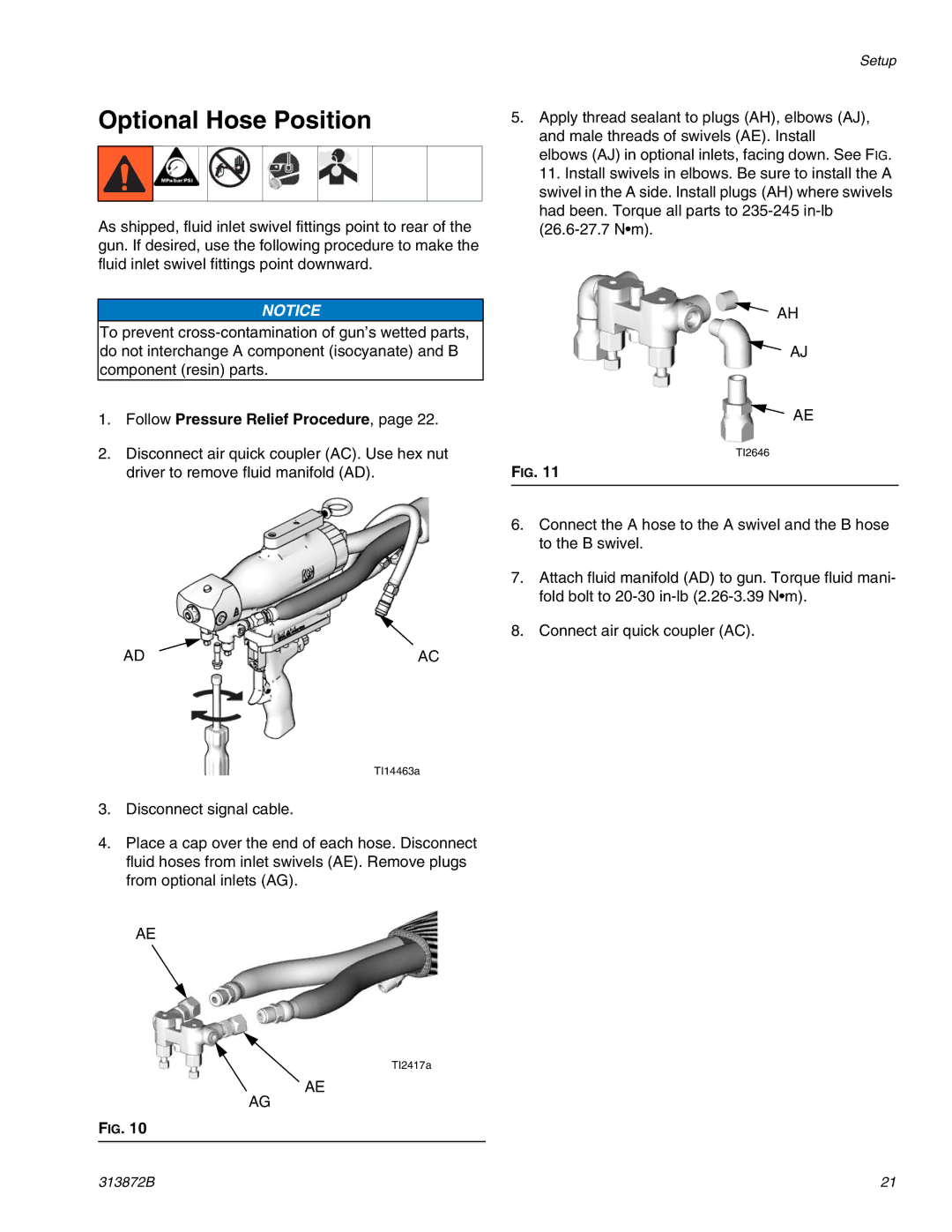

5.Apply thread sealant to plugs (AH), elbows (AJ), and male threads of swivels (AE). Install

elbows (AJ) in optional inlets, facing down. See FIG. 11. Install swivels in elbows. Be sure to install the A swivel in the A side. Install plugs (AH) where swivels had been. Torque all parts to

AH

AJ

AE

TI2646

FIG. 11

6.Connect the A hose to the A swivel and the B hose to the B swivel.

7.Attach fluid manifold (AD) to gun. Torque fluid mani- fold bolt to

8.Connect air quick coupler (AC).

313872B | 21 |