|

|

|

|

|

|

| Maintenance |

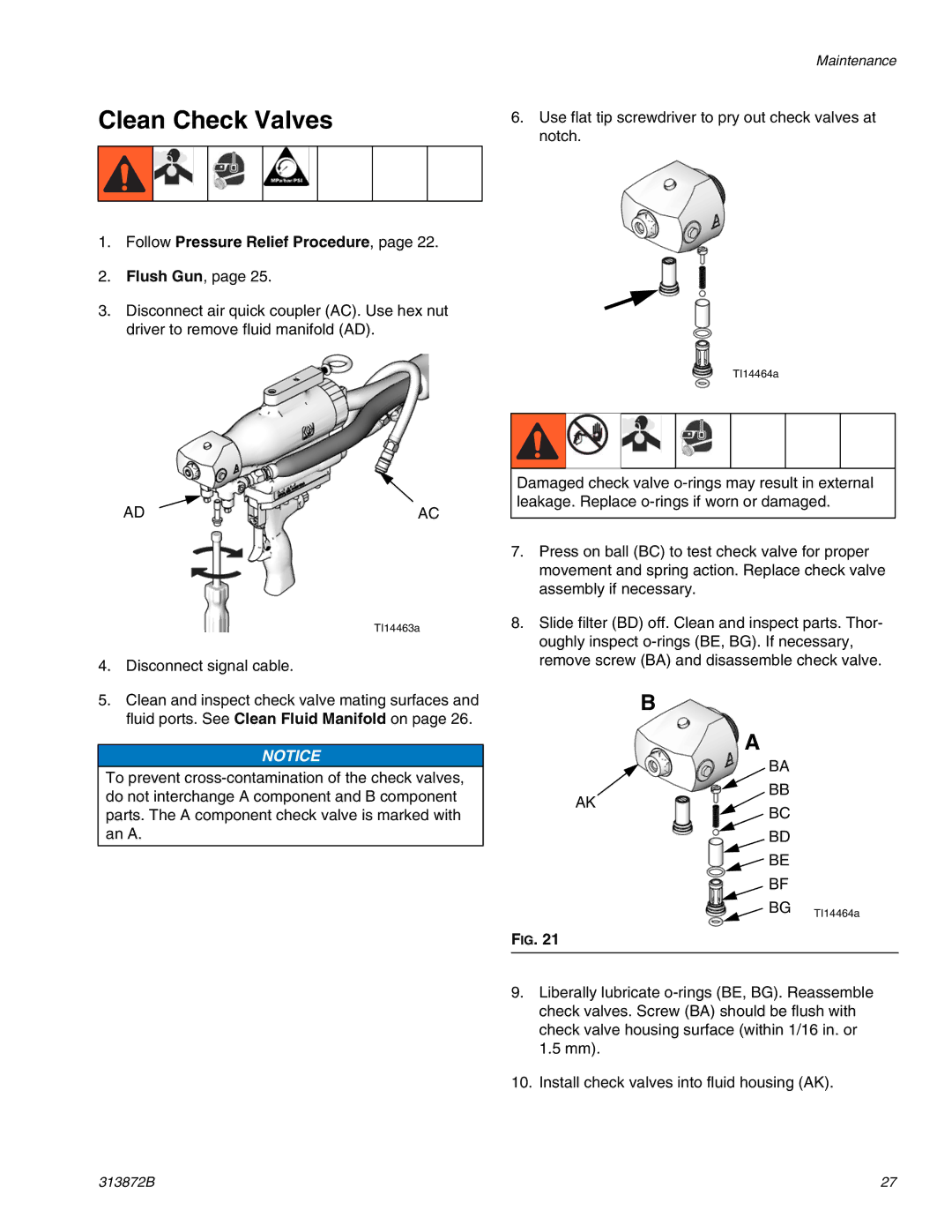

Clean Check Valves | 6. Use flat tip screwdriver to pry out check valves at | ||||||

|

|

|

|

|

|

| notch. |

|

|

|

|

|

|

|

|

1.Follow Pressure Relief Procedure, page 22.

2.Flush Gun, page 25.

3.Disconnect air quick coupler (AC). Use hex nut driver to remove fluid manifold (AD).

TI14464a

AD | AC |

TI14463a

4.Disconnect signal cable.

5.Clean and inspect check valve mating surfaces and fluid ports. See Clean Fluid Manifold on page 26.

Damaged check valve

7.Press on ball (BC) to test check valve for proper movement and spring action. Replace check valve assembly if necessary.

8.Slide filter (BD) off. Clean and inspect parts. Thor- oughly inspect

B

A

NOTICE

To prevent

AK

BA

BB

BC

BD

![]() BE

BE

BF

BG TI14464a

FIG. 21

9.Liberally lubricate

10.Install check valves into fluid housing (AK).

313872B | 27 |