LP/PROPANE TANK CONNECTION

Outdoor side burners orificed for use with LP/Propane gas come equipped with a high capacity hose/regulator assembly for connection to a standard 20 lb. LP/Propane cylinder equipped with a Type 1, QCC-1 connector. Hose assembly must comply with Elastomeric Composite Hose and Couplings for Conducting Propane and Natural Gas, CAN/CGA-8.1 standard or the Theromplastic Hose and Hose Couplings for Conducting Propane and Natural Gas CAN1-8.3 standard (See LP/Propane tank requirements below). Each tank is supplied with a dust cap. Place dust cap on cylinder valve outlet whenever the cylinder is not in use. Only install the type of dust cap on the cylinder valve outlet that is provided with the cylinder valve. Other types of caps or plugs may result in leakage of propane.

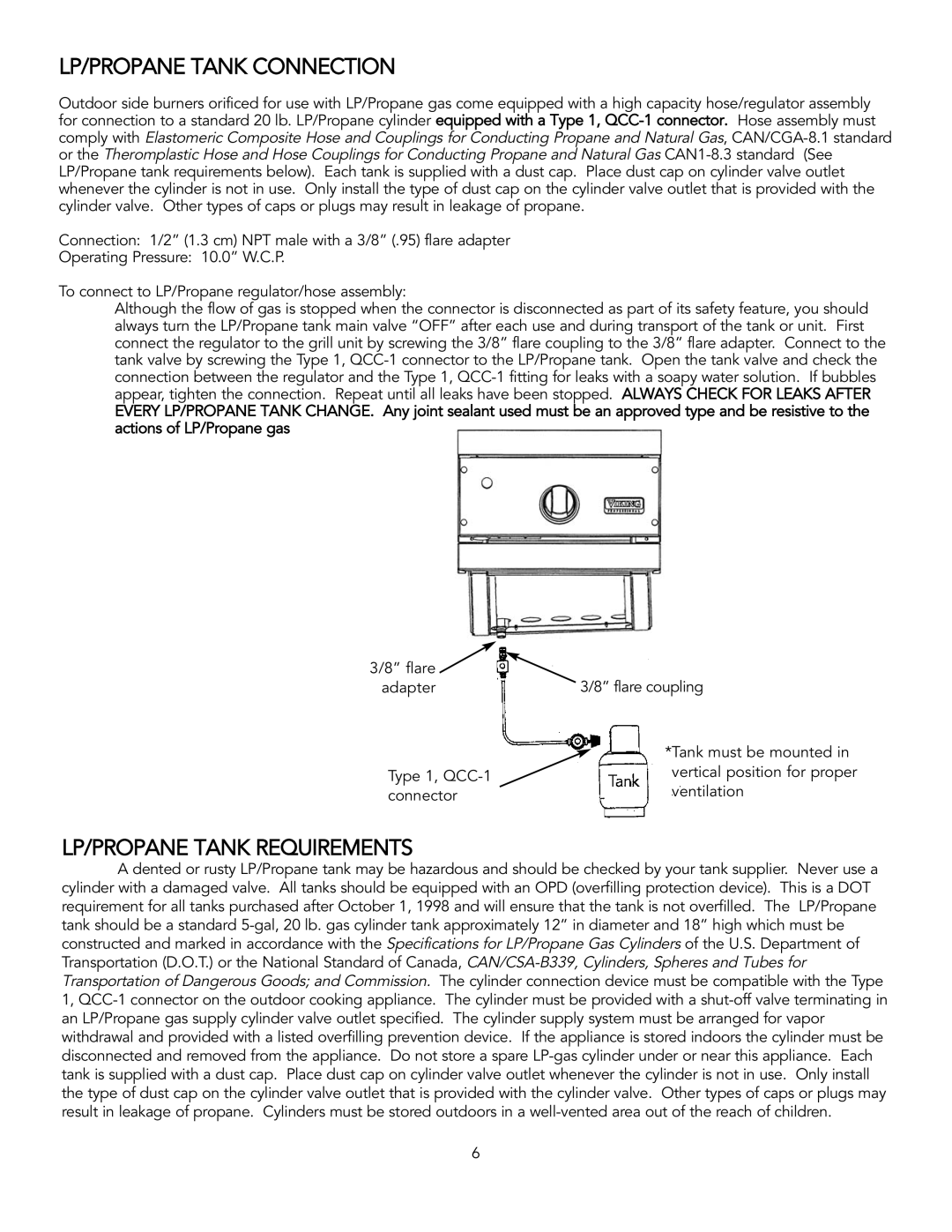

Connection: 1/2” (1.3 cm) NPT male with a 3/8” (.95) flare adapter

Operating Pressure: 10.0” W.C.P.

To connect to LP/Propane regulator/hose assembly:

Although the flow of gas is stopped when the connector is disconnected as part of its safety feature, you should always turn the LP/Propane tank main valve “OFF” after each use and during transport of the tank or unit. First connect the regulator to the grill unit by screwing the 3/8” flare coupling to the 3/8” flare adapter. Connect to the tank valve by screwing the Type 1, QCC-1 connector to the LP/Propane tank. Open the tank valve and check the connection between the regulator and the Type 1, QCC-1 fitting for leaks with a soapy water solution. If bubbles appear, tighten the connection. Repeat until all leaks have been stopped. ALWAYS CHECK FOR LEAKS AFTER EVERY LP/PROPANE TANK CHANGE. Any joint sealant used must be an approved type and be resistive to the actions of LP/Propane gas

3/8” flare | | | |

adapter | | 3/8” flare coupling | |

| | | | |

| | | *Tank must be mounted in |

| | | vertical position for proper |

| Type 1, QCC-1 |

| connector | | ventilation |

| | | | |

LP/PROPANE TANK REQUIREMENTS

A dented or rusty LP/Propane tank may be hazardous and should be checked by your tank supplier. Never use a cylinder with a damaged valve. All tanks should be equipped with an OPD (overfilling protection device). This is a DOT requirement for all tanks purchased after October 1, 1998 and will ensure that the tank is not overfilled. The LP/Propane tank should be a standard 5-gal, 20 lb. gas cylinder tank approximately 12” in diameter and 18” high which must be constructed and marked in accordance with the Specifications for LP/Propane Gas Cylinders of the U.S. Department of Transportation (D.O.T.) or the National Standard of Canada, CAN/CSA-B339, Cylinders, Spheres and Tubes for Transportation of Dangerous Goods; and Commission. The cylinder connection device must be compatible with the Type 1, QCC-1 connector on the outdoor cooking appliance. The cylinder must be provided with a shut-off valve terminating in an LP/Propane gas supply cylinder valve outlet specified. The cylinder supply system must be arranged for vapor withdrawal and provided with a listed overfilling prevention device. If the appliance is stored indoors the cylinder must be disconnected and removed from the appliance. Do not store a spare LP-gas cylinder under or near this appliance. Each tank is supplied with a dust cap. Place dust cap on cylinder valve outlet whenever the cylinder is not in use. Only install the type of dust cap on the cylinder valve outlet that is provided with the cylinder valve. Other types of caps or plugs may result in leakage of propane. Cylinders must be stored outdoors in a well-vented area out of the reach of children.