RUI/Gateway & DeviceNetTM

Configuration & Ladder Logic Example

Using an

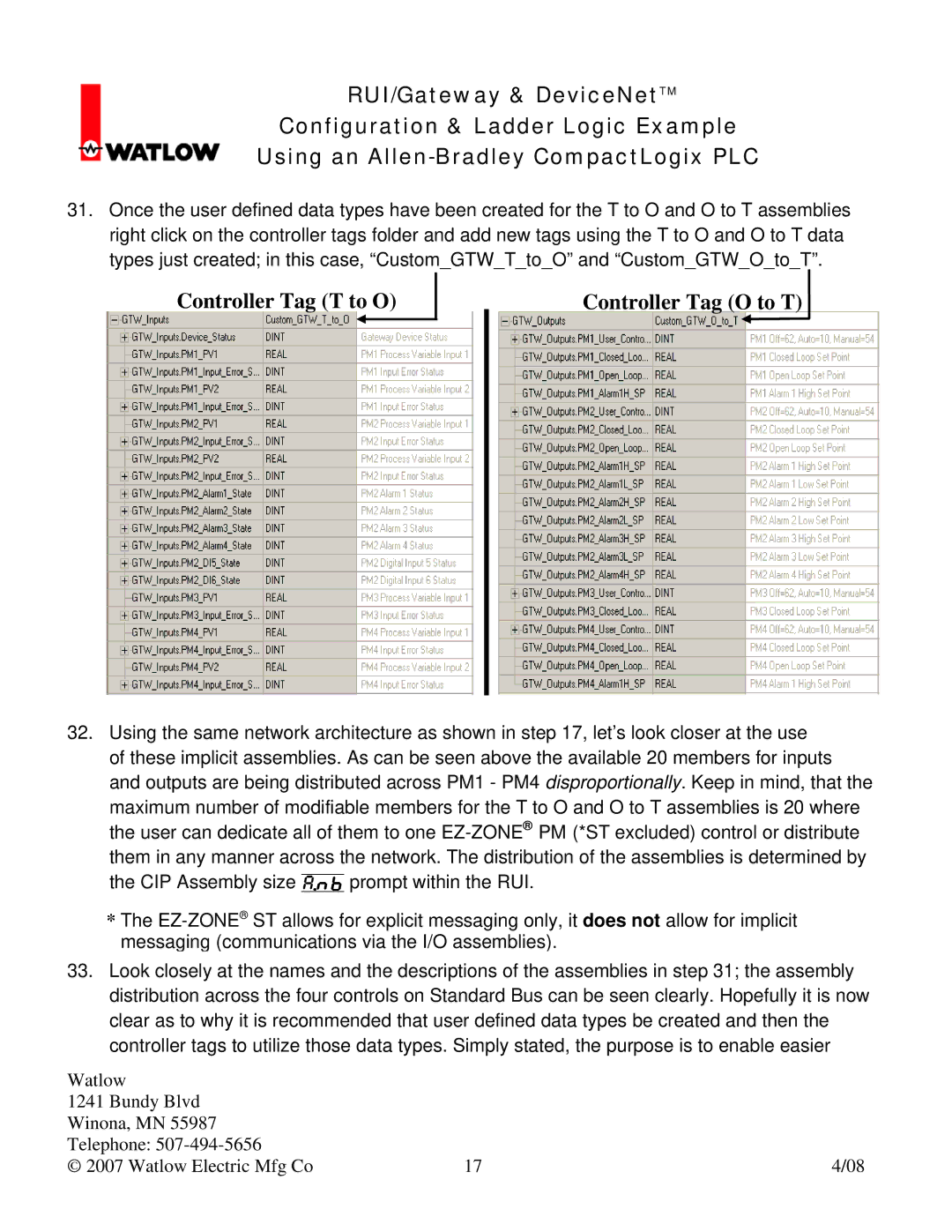

31.Once the user defined data types have been created for the T to O and O to T assemblies right click on the controller tags folder and add new tags using the T to O and O to T data types just created; in this case, “Custom_GTW_T_to_O” and “Custom_GTW_O_to_T”.

Controller Tag (T to O)

Controller Tag (O to T)

32.Using the same network architecture as shown in step 17, let’s look closer at the use of these implicit assemblies. As can be seen above the available 20 members for inputs

and outputs are being distributed across PM1 - PM4 disproportionally. Keep in mind, that the

maximum number of modifiable members for the T to O and O to T assemblies is 20 where the user can dedicate all of them to one

*The

33.Look closely at the names and the descriptions of the assemblies in step 31; the assembly distribution across the four controls on Standard Bus can be seen clearly. Hopefully it is now clear as to why it is recommended that user defined data types be created and then the controller tags to utilize those data types. Simply stated, the purpose is to enable easier

Watlow |

|

|

1241 Bundy Blvd |

|

|

Winona, MN 55987 |

|

|

Telephone: |

|

|

© 2007 Watlow Electric Mfg Co | 17 | 4/08 |