Safety Guidelines

General Safety Information

GENERAL SAFETY

7.Personal Safety

General Safety Information Continued

Pre-Installation

PRESSURE SWITCH

CWS50, CWS75 and CWS100

Installation

SHALLOW WELL INSTALLATION

Continued

PACKAGE SYSTEMS

Installation Continued

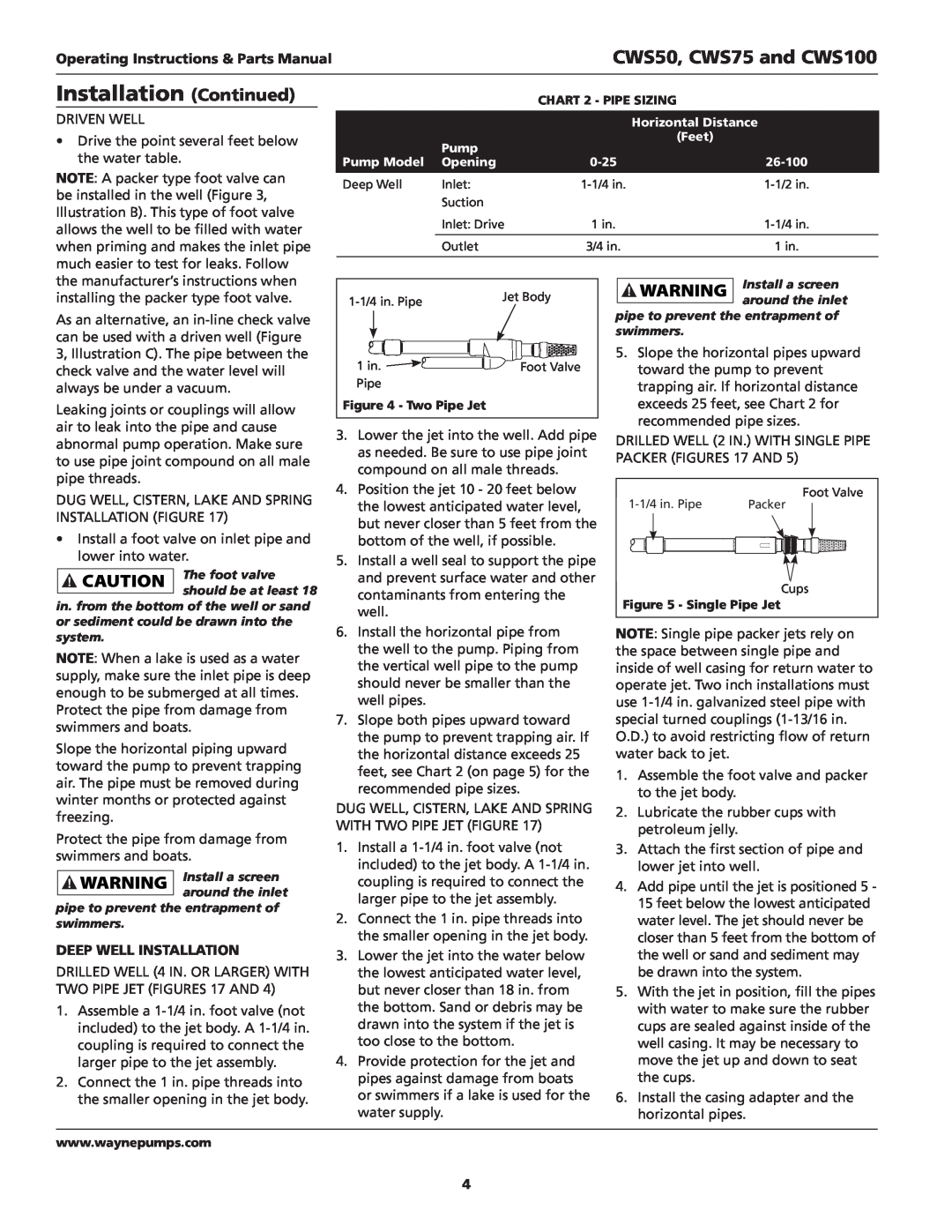

DEEP WELL INSTALLATION

CWS50, CWS75 and CWS100

Operating Instructions & Parts Manual

Electrical

Installation Continued

Maintenance

Electrical Continued

Operation

PRIMING THE SHALLOW WELL PUMP

Maintenance Continued

INSTALLING NEW SHAFT SEAL

PRE-CHARGEDTANK

LUBRICATION

ASPRING BLAKE STREAM, POND

C DUG WELL

E DRILLED WELL

D DRIVEN WELL

CWS50, CWS75 and CWS100

Troubleshooting Chart

Operating Instructions & Parts Manual

Replacement Parts List

Please provide following information

Address any correspondence to

Model number

Performance

Limited Warranty

ATTACH YOUR RECEIPT HERE

CWS50, CWS75 and CWS100

Operating Instructions & Parts Manual

Puit convertible Systèmes DEau De Pompe À Jet

Déballage

Directives de Sécurité

Généralités Sur La Sécurité

Pré-Installation

Généralités Sur La Sécurité Suite

CWS50, CWS75 et CWS100

Instructions D’utilisation et Manual de Pièces

Pré-Installation Suite

INSTALLATION DE PUITS DE SURFACE

SYSTÈMES EN PAQUETS

PUITS

Installation Suite

INSTALLATION POUR PUITS PROFOND

16-Fr

CWS50, CWS75 et CWS100

Électrique Suite

17-Fr

Installation Suite

CWS50, CWS75 et CWS100

Fonctionnement

Entretien

AMORÇAGE DE LA POMPE POUR PUITS DE SURFACE

AMORÇAGE DE LA POMPE POUR PUITS PROFOND

INSTALLATION D’UN NOUVEAU JOINT D’ARBRE

Entretien Suite

RÉSERVOIRS SATURÉS D’EAU CHARGÉS D’AVANCE

RÉSERVOIR CHARGÉ D’AVANCE

C PUITS CREUSÉ

E PUITS FORÉ

À EAU

D PUITS ENFONCÉ

Tableau de dépannage

21-Fr

CWS50, CWS75 et CWS100

Instructions D’utilisation et Manual de Pièces

Liste de pièces de rechange

S’il vous plaît fournir l’information suivante

Adresser toute correspondance à

22-Fr

23-Fr

Performance

Pression de Décharge kPa

12,2

Garantie Limitée

24-Fr

CWS50, CWS75 et CWS100

Instructions D’utilisation et Manual de Pièces

Pozo convertible Sistemas de Agua Con

Bomba de Chorro

Descripción

Para Desempacar

Pre-Instalación

CWS50, CWS75, y CWS100

Manual de instrucciones de operación y piezas

FUENTES DE SUMINISTRO DE AGUA

Pre-Instalación Continued

Instalación

PAQUETES DE SISTEMAS

POZOS

Instalación Continued

INSTALACIÓN EN UN PROFUNDO

28-Sp

CWS50, CWS75, y CWS100

Eléctricas

29-Sp

Instalación Continued

CWS50, CWS75, y CWS100

Funcionamiento

Mantenimiento

CEBADO DE LA BOMBA PARA POZOS POCO PROFUNDOS

CEBADO DE LA BOMBA PARA POZOS PROFUNDOS

Eléctricas Continued

DRENAJE DEL TONQUE

PRECARGADO

PARA VOLVER A HACER FUNCIONAR LA BOMBA

32-Sp

Mantenimiento

CWS50, CWS75, y CWS100

Continued

Tabla de Identificación de Problemas

33-Sp

CWS50, CWS75, y CWS100

Manual de instrucciones de operación y piezas

Lista de Partes de Reparación

Sirvase darnos la siguiente información

Dirija toda la correspondencia a

Número del modelo

Rendimiento

35-Sp

Presión de Descarga bar

1,38

Garantía Limitada

ANEXE SU RECIBO AQUI

36-Sp

CWS50, CWS75, y CWS100