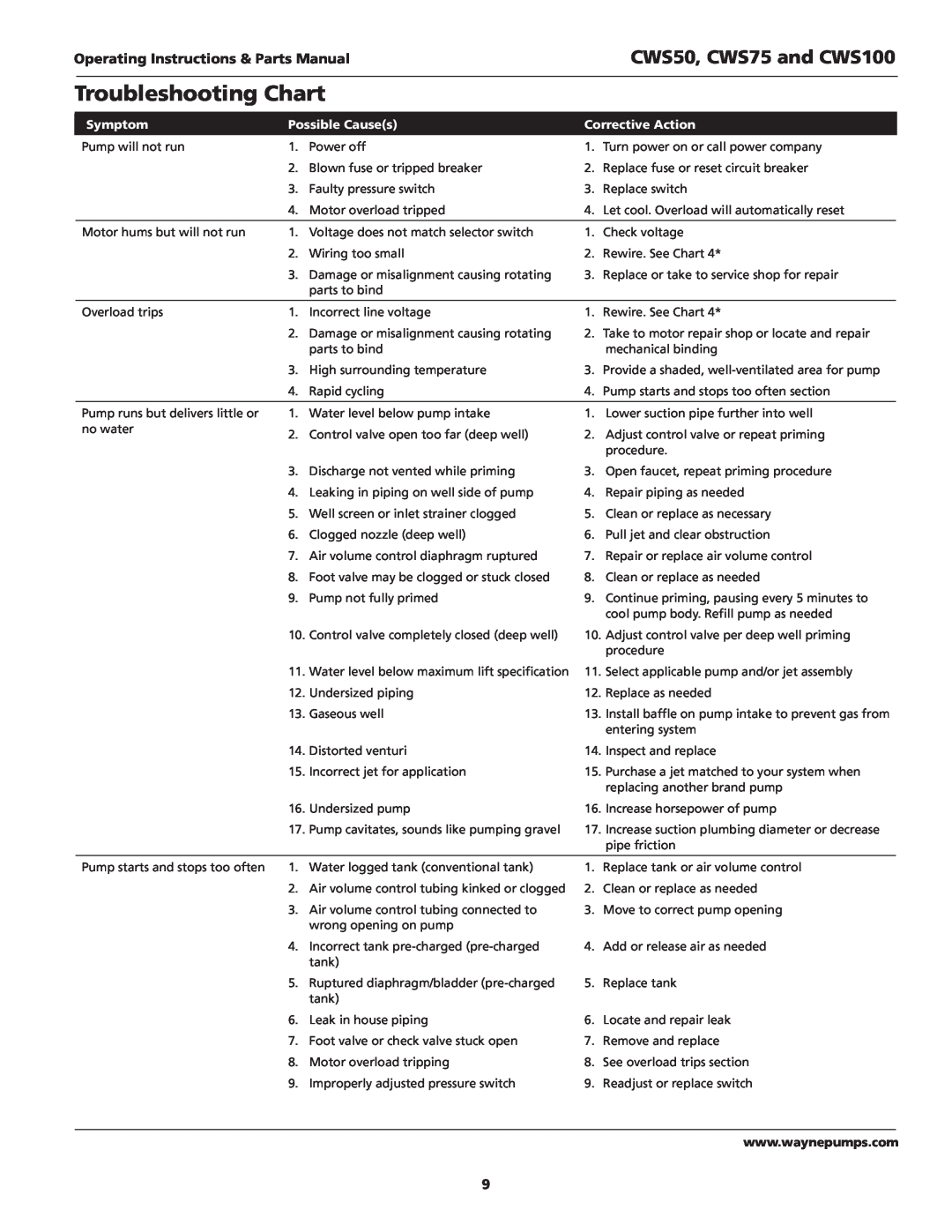

Operating Instructions & Parts Manual | CWS50, CWS75 and CWS100 |

Troubleshooting Chart

Symptom

Possible Cause(s)

Corrective Action

Pump will not run | 1. | Power off | 1. | Turn power on or call power company |

| 2. | Blown fuse or tripped breaker | 2. | Replace fuse or reset circuit breaker |

| 3. | Faulty pressure switch | 3. | Replace switch |

| 4. | Motor overload tripped | 4. | Let cool. Overload will automatically reset |

|

|

|

|

|

Motor hums but will not run | 1. | Voltage does not match selector switch | 1. | Check voltage |

| 2. | Wiring too small | 2. | Rewire. See Chart 4* |

| 3. | Damage or misalignment causing rotating | 3. | Replace or take to service shop for repair |

|

| parts to bind |

|

|

|

|

|

|

|

Overload trips | 1. | Incorrect line voltage | 1. | Rewire. See Chart 4* |

| 2. | Damage or misalignment causing rotating | 2. | Take to motor repair shop or locate and repair |

|

| parts to bind |

| mechanical binding |

| 3. | High surrounding temperature | 3. | Provide a shaded, |

| 4. | Rapid cycling | 4. | Pump starts and stops too often section |

|

|

|

|

|

Pump runs but delivers little or | 1. | Water level below pump intake | 1. | Lower suction pipe further into well |

no water | 2. | Control valve open too far (deep well) | 2. | Adjust control valve or repeat priming |

| ||||

|

|

|

| procedure. |

| 3. | Discharge not vented while priming | 3. | Open faucet, repeat priming procedure |

| 4. | Leaking in piping on well side of pump | 4. | Repair piping as needed |

| 5. | Well screen or inlet strainer clogged | 5. | Clean or replace as necessary |

| 6. | Clogged nozzle (deep well) | 6. | Pull jet and clear obstruction |

| 7. | Air volume control diaphragm ruptured | 7. | Repair or replace air volume control |

| 8. | Foot valve may be clogged or stuck closed | 8. | Clean or replace as needed |

| 9. | Pump not fully primed | 9. | Continue priming, pausing every 5 minutes to |

|

|

|

| cool pump body. Refill pump as needed |

| 10. | Control valve completely closed (deep well) | 10. | Adjust control valve per deep well priming |

|

|

|

| procedure |

| 11. | Water level below maximum lift specification | 11. | Select applicable pump and/or jet assembly |

| 12. | Undersized piping | 12. | Replace as needed |

| 13. | Gaseous well | 13. | Install baffle on pump intake to prevent gas from |

|

|

|

| entering system |

| 14. | Distorted venturi | 14. | Inspect and replace |

| 15. | Incorrect jet for application | 15. | Purchase a jet matched to your system when |

|

|

|

| replacing another brand pump |

| 16. | Undersized pump | 16. | Increase horsepower of pump |

| 17. | Pump cavitates, sounds like pumping gravel | 17. | Increase suction plumbing diameter or decrease |

|

|

|

| pipe friction |

|

|

|

|

|

Pump starts and stops too often | 1. | Water logged tank (conventional tank) | 1. | Replace tank or air volume control |

| 2. | Air volume control tubing kinked or clogged | 2. | Clean or replace as needed |

| 3. | Air volume control tubing connected to | 3. | Move to correct pump opening |

|

| wrong opening on pump |

|

|

| 4. | Incorrect tank | 4. | Add or release air as needed |

|

| tank) |

|

|

| 5. | Ruptured diaphragm/bladder | 5. | Replace tank |

|

| tank) |

|

|

| 6. | Leak in house piping | 6. | Locate and repair leak |

| 7. | Foot valve or check valve stuck open | 7. | Remove and replace |

| 8. | Motor overload tripping | 8. | See overload trips section |

| 9. | Improperly adjusted pressure switch | 9. | Readjust or replace switch |

www.waynepumps.com

9