GAS SUPPLY

Note: Leave an access in the“island” structure for gas supply and regulator service that is not inside the grill structure.

Note: Area should be kept clear of sharp, jagged, or extremely abrasive surfaces to avoid possible damage to gas supply lines. Exercise caution when pulling gas lines through

TYPICAL NATURAL GAS SUPPLY INSTALLATION

We recommend that this installation be done by a LICENSED professional.

General Specifications For Piping

Note - Contact your local municipality for building codes regulating outdoor gas grill installations. In absence of Local Codes, you must conform to the latest edition of National Fuel Gas Code ANSI Z223.1/NFPA54.

•This grill is designed to operate at 4.5 inches of water column pressure.

•A manual

mCAUTION: If young children are in the area, a locking valve should be considered.

•Pipe compound should be used which is resistant to the action of liquid propane gas when gas connections are made.

•The gas connections must be firmly attached to a rigid, permanent construction.

Note: The information provided in this manual is general for typical installations. We cannot cover all possible installation ideas. We recommend, prior to installation, that you contact your municipality for local building codes and your local fire department for installation verification.

If you have any questions, contact Customer Service at

GAS LINE PIPING

•Refer to piping chart.

•The corrugated gas line from the manifold is 58" (1,473.2 mm) long. Do not extend the gas line.

•We have provided the means to make an SAE 45° flare connection. Do not use pipe sealant on this connection.

•If the length of line required does not exceed 50 feet, use a 5/8" O.D. tube. One size larger should be used for lengths greater than 50 feet. Refer to piping chart.

•Gas piping may be copper tubing, type K or L; polyethylene plastic tube, with a minimum wall thickness of .062" (1.57 mm); or standard weight (schedule 40) steel or wrought iron pipe.

•Copper tubing must be

•Plastic tubing is suitable only for outdoor, underground use.

•Gas piping in contact with earth, or any other material which may corrode the piping, must be protected against corrosion in an approved manner.

•Underground piping must have a minimum of 18" cover. ◆

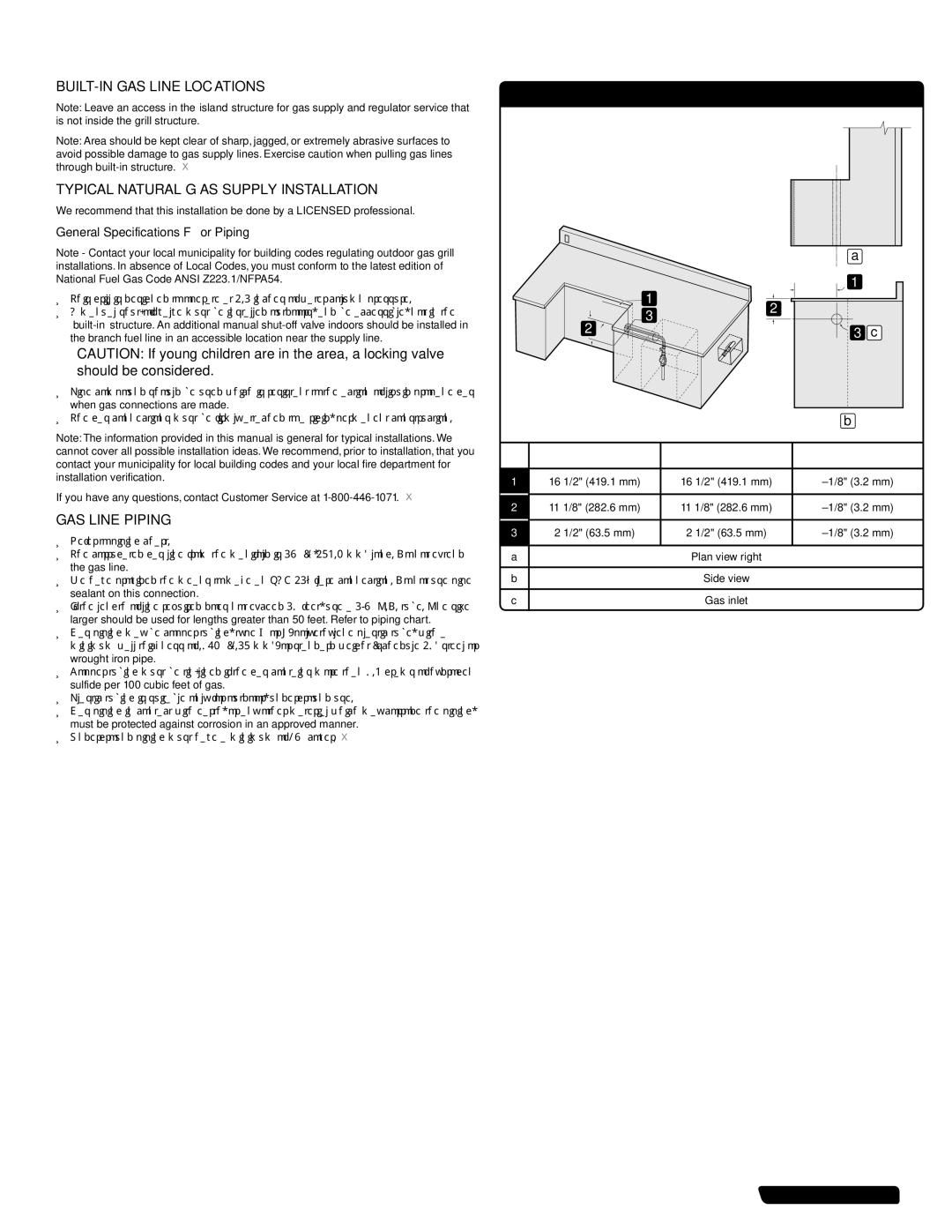

BUILT-IN GAS LINE LOCATIONS

|

|

|

| a |

|

|

|

| 1 |

|

| 1 | 2 |

|

|

| 3 |

| |

| 2 |

| 3 c | |

|

|

| ||

|

|

|

| b |

| 460 |

| 660 | TOLERANCES |

1 | 16 1/2" (419.1 mm) |

| 16 1/2" (419.1 mm) | ±1/8" (3.2 mm) |

2 | 11 1/8" (282.6 mm) |

| 11 1/8" (282.6 mm) | ±1/8" (3.2 mm) |

3 | 2 1/2" (63.5 mm) |

| 2 1/2" (63.5 mm) | ±1/8" (3.2 mm) |

a |

|

| Plan view right |

|

b |

|

| Side view |

|

c |

|

| Gas inlet |

|

www.weber.com® 23