Connect Steam Piping

General piping information:

•Hartford Loop piping arrangement and wet return are required for steam boilers.

•Maintain

•When using condensate receiver, feed pump must be energized by

•Use swing joints in steam piping.

•If installation is to comply with ASME or Canadian requirements, an additional pressure limit control is needed. Install control between existing pressure control and pressure gauge. Control must be installed with siphon (supplied with boiler) between control and boiler. Set control to minimum of 5 psi above setpoint of existing control and maximum setting of 15 psi. Wire as shown on boiler wiring diagram.

Install piping:

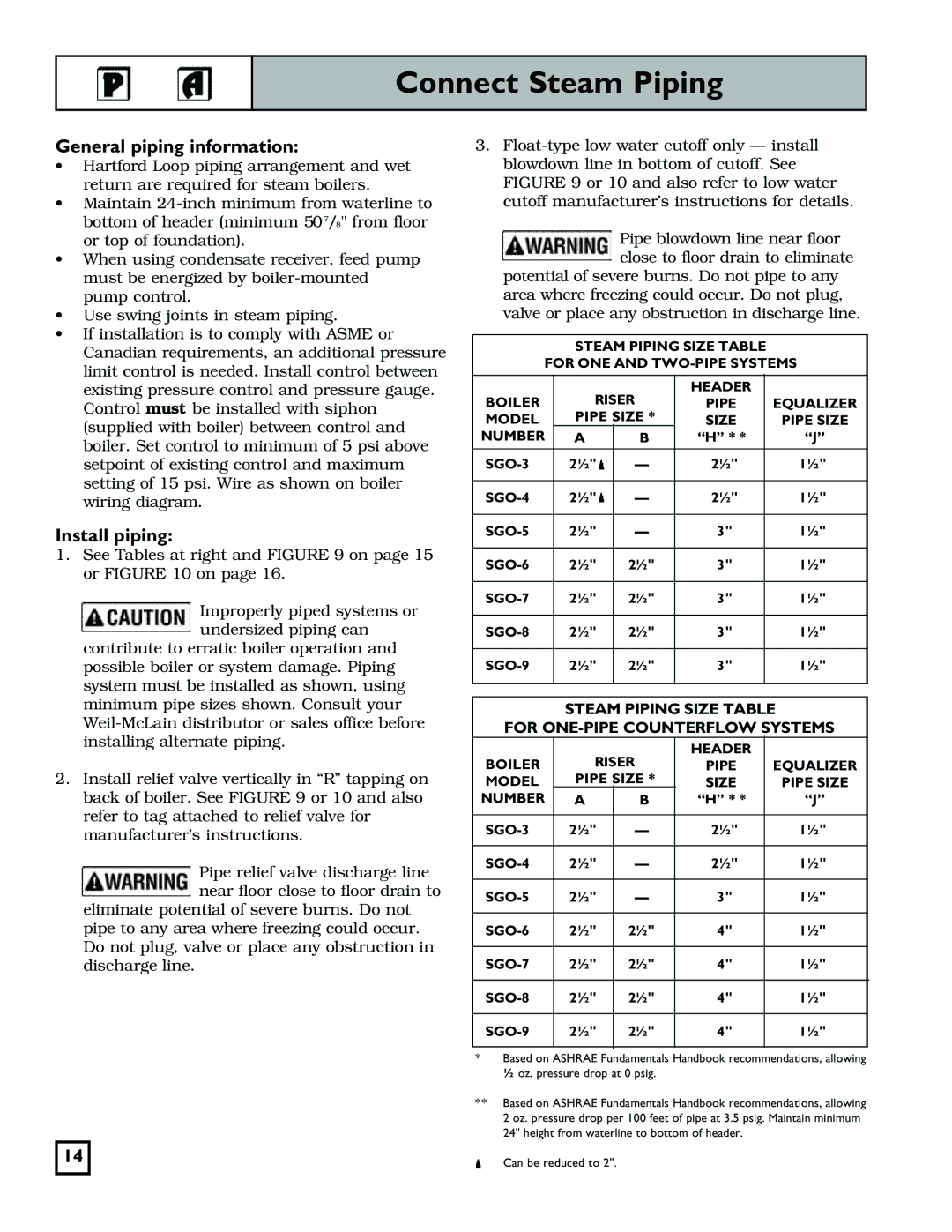

1.See Tables at right and FIGURE 9 on page 15 or FIGURE 10 on page 16.

Improperly piped systems or undersized piping can

contribute to erratic boiler operation and possible boiler or system damage. Piping system must be installed as shown, using minimum pipe sizes shown. Consult your

2.Install relief valve vertically in “R” tapping on back of boiler. See FIGURE 9 or 10 and also refer to tag attached to relief valve for manufacturer’s instructions.

Pipe relief valve discharge line near floor close to floor drain to

eliminate potential of severe burns. Do not pipe to any area where freezing could occur. Do not plug, valve or place any obstruction in discharge line.

14

3.

Pipe blowdown line near floor close to floor drain to eliminate

potential of severe burns. Do not pipe to any area where freezing could occur. Do not plug, valve or place any obstruction in discharge line.

STEAM PIPING SIZE TABLE

FOR ONE AND

|

|

|

| RISER |

|

| HEADER |

|

|

| |||

|

|

|

|

|

|

|

|

| |||||

| BOILER |

|

|

|

| PIPE |

| EQUALIZER |

| ||||

| MODEL |

|

| PIPE SIZE * |

|

| SIZE |

| PIPE SIZE |

| |||

| NUMBER |

|

| A | B |

|

| “H” * * |

| “J” |

| ||

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

| ||||

|

| 2½" |

| — |

| 2½" | 1½" |

| |||||

|

|

|

|

| |||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 2½" |

| — |

| 2½" | 1½" |

| |||||

|

|

|

|

| |||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 2½" |

| — |

| 3" | 1½" |

| |||||

|

|

|

|

|

|

|

|

|

|

|

| ||

|

| 2½" |

| 2½" |

|

|

| 3" | 1½" |

| |||

|

|

|

|

|

|

|

|

|

|

|

| ||

|

| 2½" |

| 2½" |

|

|

| 3" | 1½" |

| |||

|

|

|

|

|

|

|

|

|

|

|

| ||

|

| 2½" |

| 2½" |

|

|

| 3" | 1½" |

| |||

|

|

|

|

|

|

|

|

|

|

|

| ||

|

| 2½" |

| 2½" |

|

|

| 3" | 1½" |

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

STEAM PIPING SIZE TABLE

FOR ONE-PIPE COUNTERFLOW SYSTEMS

|

|

|

|

|

|

|

|

|

| HEADER |

|

|

|

|

|

|

|

| RISER |

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

| ||||

| BOILER |

|

|

|

|

| PIPE |

| EQUALIZER |

|

| |||

| MODEL |

|

| PIPE SIZE * |

|

|

| SIZE |

| PIPE SIZE |

|

| ||

| NUMBER |

|

| A | B |

|

|

| “H” * * |

| “J” |

|

| |

|

|

|

|

|

|

|

|

|

|

| ||||

|

| 2½" | — |

| 2½" | 1½" |

|

| ||||||

|

|

|

|

|

|

|

|

|

|

| ||||

|

| 2½" | — |

| 2½" | 1½" |

|

| ||||||

|

|

|

|

|

|

|

|

|

|

| ||||

|

| 2½" | — |

| 3" | 1½" |

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

| 2½" | 2½" |

|

|

|

| 4" | 1½" |

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

| 2½" | 2½" |

|

|

|

| 4" | 1½" |

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

| 2½" | 2½" |

|

|

|

| 4" | 1½" |

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

| 2½" | 2½" |

|

|

|

| 4" | 1½" |

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

*Based on ASHRAE Fundamentals Handbook recommendations, allowing ½ oz. pressure drop at 0 psig.

** Based on ASHRAE Fundamentals Handbook recommendations, allowing 2 oz. pressure drop per 100 feet of pipe at 3.5 psig. Maintain minimum 24" height from waterline to bottom of header.

Can be reduced to 2".