GOLD

11a Troubleshooting — procedure

Label all wires prior to disconnection when servicing controls. Wiring errors can cause improper and dangerous operation.

Never jumper (bypass) rollout thermal fuse element or any other

device except for momentary testing as outlined in Troubleshooting

Charts. Severe personal injury, death or substantial property damage

can result.

Before troubleshooting:

1.Have the following items:

a.Voltmeter that can check 120 VAC and 24 VAC.

b.Microammeter with a minimum scale range of

c.Continuity checker.

d.

2.Check for 120 VAC (minimum 102 VAC to maximum 132 VAC) to boiler.

3.Make sure thermostat is calling for heat and contacts (including appropriate zone controls) are closed. Check for 24 VAC between thermostat wire nuts and ground.

Check the following:

1.Wire connectors to control module are securely plugged in at module and originating control.

2.Air pressure switch hoses are properly and securely plugged in and are not damaged.

3.Verify gas supply pressure:

a.With boiler OFF — 13” w.c. maximum natural or propane gas pressure upstream of gas valve.

b.With boiler ON — Upstream: 5” w.c. minimum natural gas pressure or 11” w.c. propane gas pressure upstream of gas valve.

4.Verify gas manifold pressure (downstream of gas valve):

a.Natural gas:

Manifold pressure, high fire: 3.50” w.c.

Manifold pressure, low fire: 0.90” w.c. while in low fire at

b.Propane gas:

Manifold pressure, high fire: 10.0” w.c.

Manifold pressure, low fire: 3.50” w.c. while in low fire at

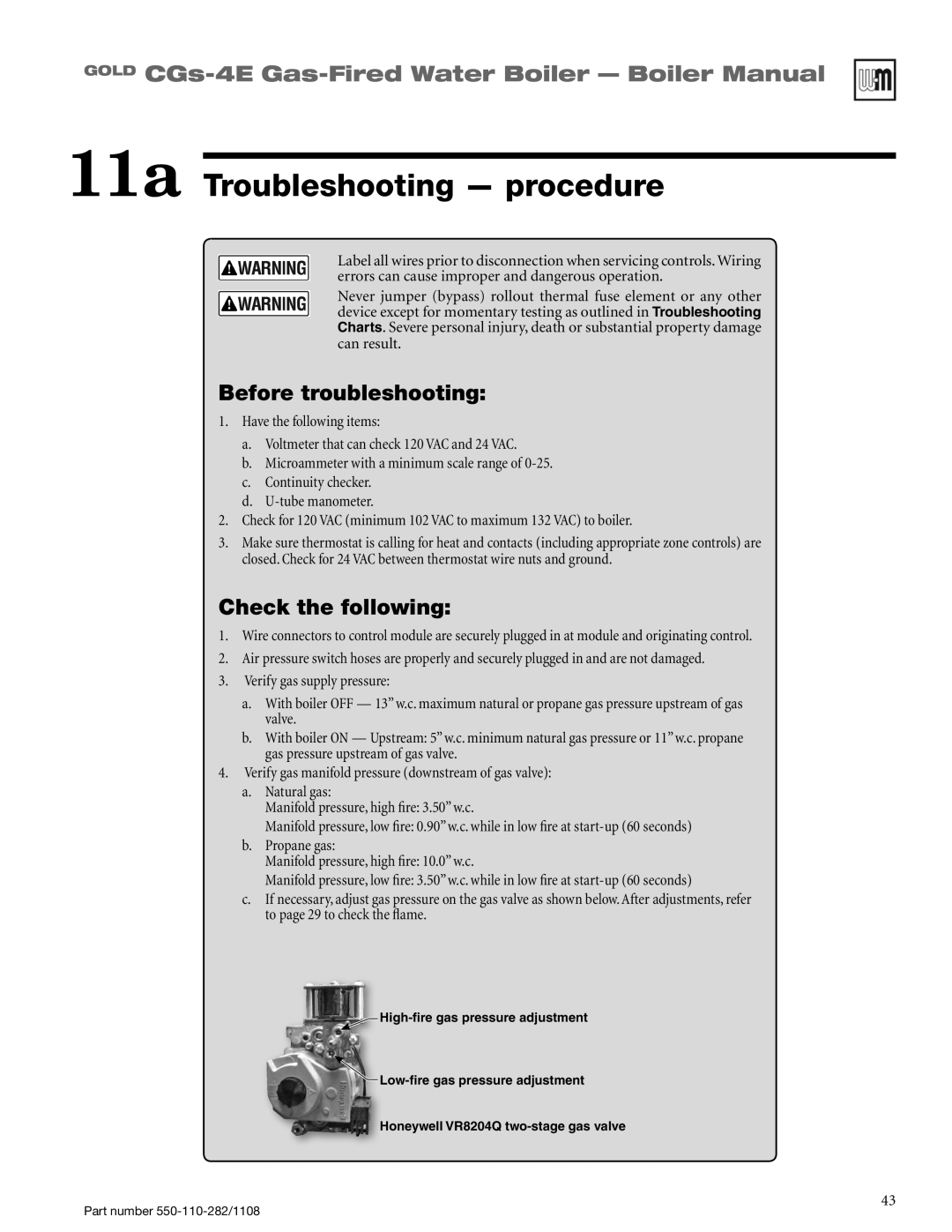

c.If necessary, adjust gas pressure on the gas valve as shown below. After adjustments, refer to page 29 to check the flame.

![]() Low-fire

Low-fire

Honeywell VR8204Q

Part number

43