GOLD

1d Prepare boiler location — contamination

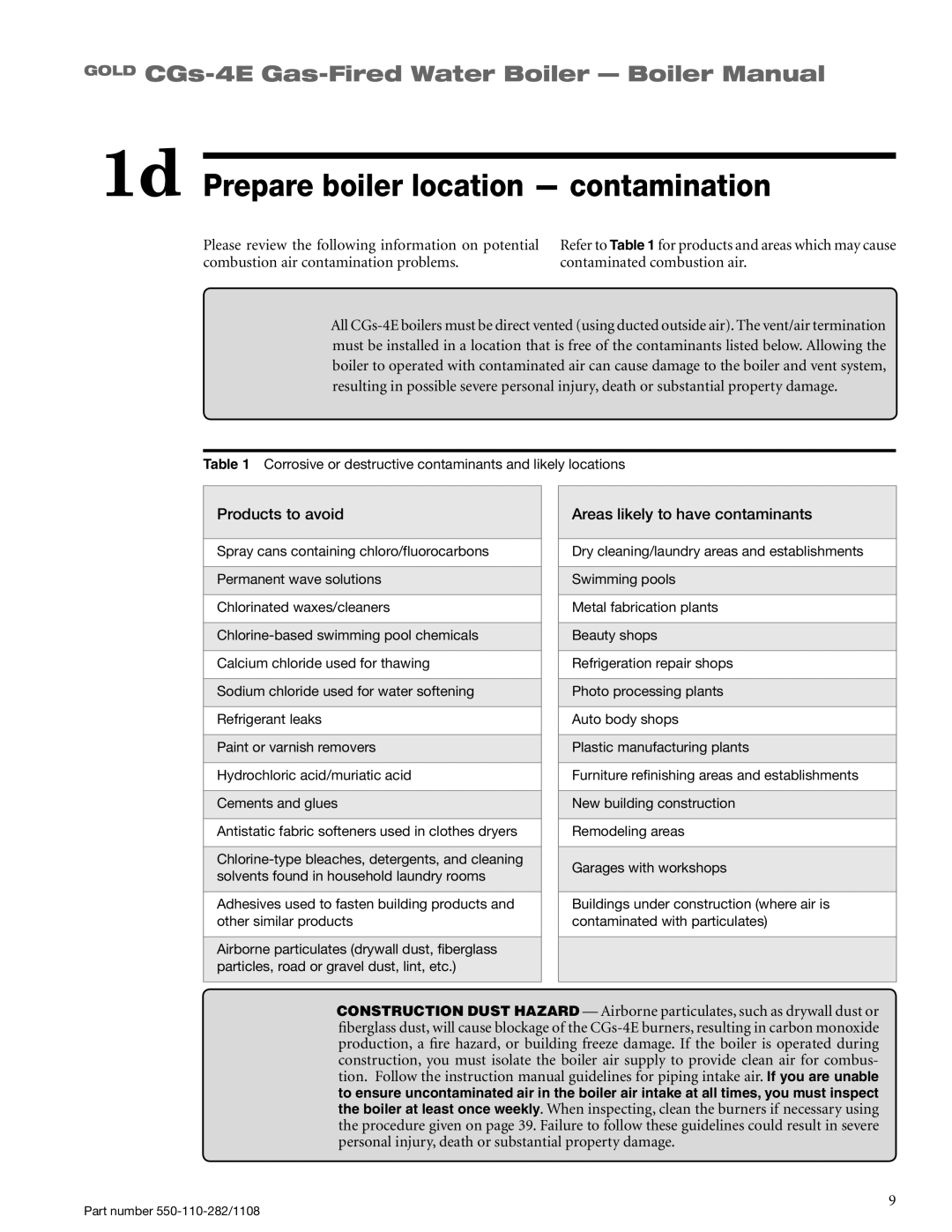

Please review the following information on potential combustion air contamination problems.

Refer to Table 1 for products and areas which may cause contaminated combustion air.

All

Table 1 Corrosive or destructive contaminants and likely locations

Products to avoid

Spray cans containing chloro/fluorocarbons

Permanent wave solutions

Chlorinated waxes/cleaners

Calcium chloride used for thawing

Sodium chloride used for water softening

Refrigerant leaks

Paint or varnish removers

Hydrochloric acid/muriatic acid

Cements and glues

Antistatic fabric softeners used in clothes dryers

Adhesives used to fasten building products and other similar products

Airborne particulates (drywall dust, fiberglass particles, road or gravel dust, lint, etc.)

Areas likely to have contaminants

Dry cleaning/laundry areas and establishments

Swimming pools

Metal fabrication plants

Beauty shops

Refrigeration repair shops

Photo processing plants

Auto body shops

Plastic manufacturing plants

Furniture refinishing areas and establishments

New building construction

Remodeling areas

Garages with workshops

Buildings under construction (where air is contaminated with particulates)

CONSTRUCTION DUST HAZARD — Airborne particulates, such as drywall dust or fiberglass dust, will cause blockage of the

Part number

9