Tools needed for installation:

adjustable | wrench | dew | glasses | |

utility | knife |

| level |

|

Phillips | screwdriver | pliers |

| |

| duct | tape | ||

screwdriver |

| gloves |

| |

Parts supplied | for | |||

installation: |

|

| ||

2 | slide protectors | 8 screws |

| |

2 | slide extensions | 2, | cams | |

2 | bolt and washer | cams | ||

| assemblies | 4.314” | wood | screws |

Parts owner | must | |||

supply:

1 control panel lock and key

2 coin vaults and keys (E.S.D. vault must have projecting lock.)

2

Parts may be ordered from Greenwald Industries, Inc. or Equipment Systems and Devices, Inc.

l Greenwald Industries, Inc.

1340 Metropolitan Avenue Brooklyn, NY 11237 telephone (7 18) 82

l Equipment Systems and Devices, Inc.

270 New Jersey Dr.

Fort Washington, PA 19034 telephone (215)

fax (215)

lMonarch P.O. Box 427

Gas supply reauhements

Fire Hazard

Dryers must be connected to a regulated gas supply.

Failure to do so could result In hlgh- pressure gas release, resulting In a fire or exploslon.

Have L.P.gas checked by a quallfled person bdore lnstalllng the dryer. The L.P.gas supply must not exceed 13 Inches water column pressure.

New, flexible tublng should be used. Reuslng old, flexible tublng mlght result In possible gas leaks.

Failure to follow these lnstructlons could result In flre or exploslon.

OBSERVEALL GOVERNING CODES AND ORDINANCES.

A n This installation must conform with American National Standard, National Fuel Gas Code ANSI Z223.1- latest edition,* and all local codes and ordinances.

B n The desian of this drver has been certified by the American Gas Association for use at altitudes up to 3000 m (10.000 feet) above sea level at the B.T.U. rating indicated on the model/serial rating plate. Burner input adjustments are not required when the dryer is operated up to this elevation.

When installed above 3000 m (10,000 feet), a four percent (4%) reduction of the burner B.T.U. rating shown on the model/serial rating plate is required

for each 300 m (1 ,ooO foot) increase in elevation, For assistance when converting to other gas types and/or installing above 3000 m (10,000 feet) elevation, contact your local service company.

C n Check that dryers are equipped with the correct burner for the particular type of gas used. Burner information will be found on the rating plate in door well of the appliance. If thls information does not agree with the type of gas available, see your dealer.

D n These dryers are shipped for use with NATURAL GAS.

They are certified by the American Gas Association for

manufactured, mixed and L.P. (propane and butane) gases with appropriate conversion. No attempt shall be made to convert the appliance from the gas specified on the model/serial rating plate for use with a different gas without consulting the serving gas suppller. Converslon must be done by a quallfled service technlclan. Gas converslon klt part numbers are llsted on the gas valve burner base.

E n Provide a rlgld gas supply line

of

(20 feet), larger pipe will be needed. For L.P. gas usage,

fge | with L.P. gas should be used |

F n If local codes and ordinances

permit, it is recommended that new flexible metal tubing,

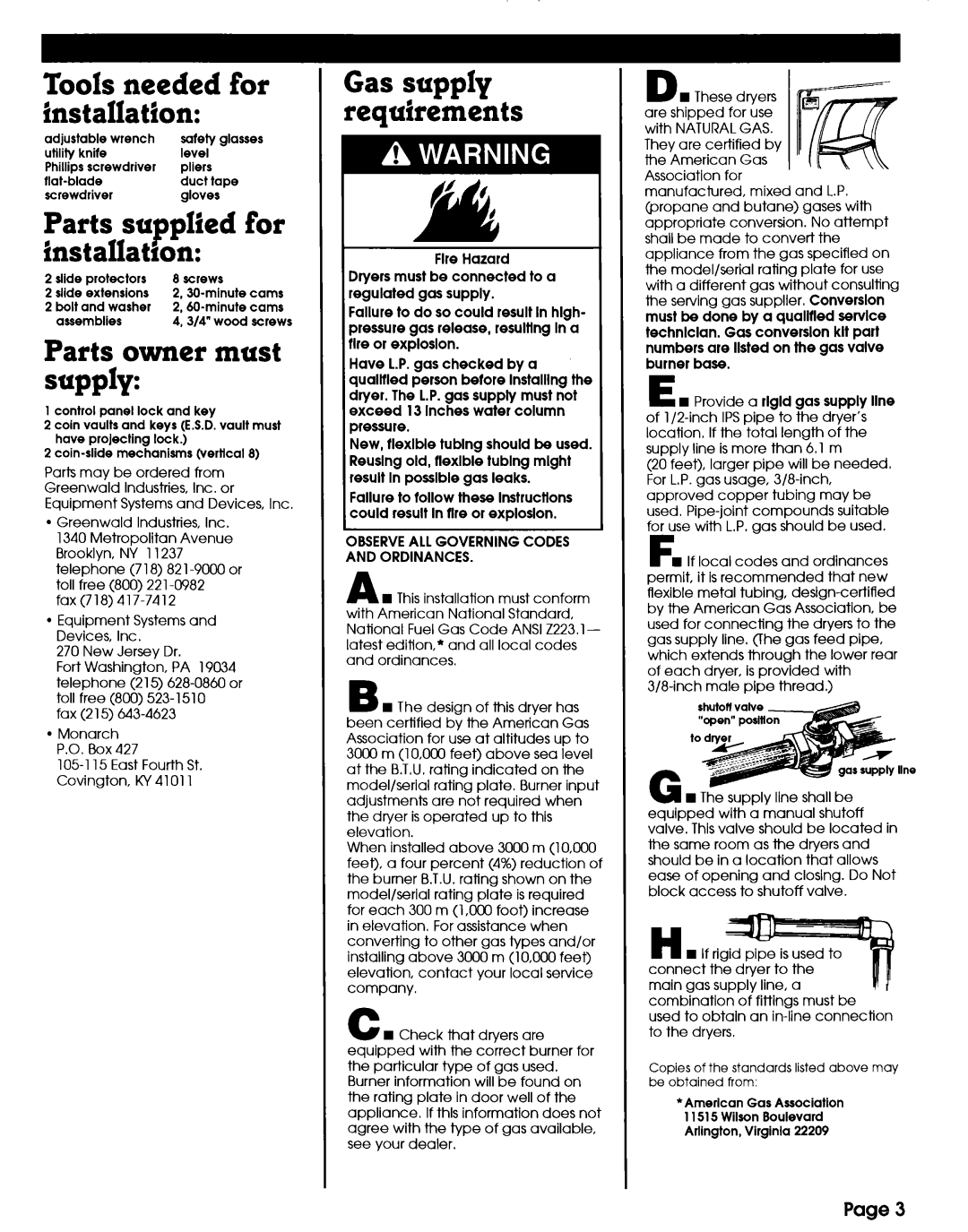

G w The SUDDIV line shall be equipped with a manual shutoff valve. This valve should be located in the same room as the dryers and should be in a location that allows ease of opening and closing. Do Not block access to shutoff valve.

H.

connec

main gas supply line, a combination of fittings must be used to obtaln an

Copies of the standards listed above may be obtained from:

*American Gas Association

11515 Wilson Boulevard

Arlington, Virginla 22209

Page 3