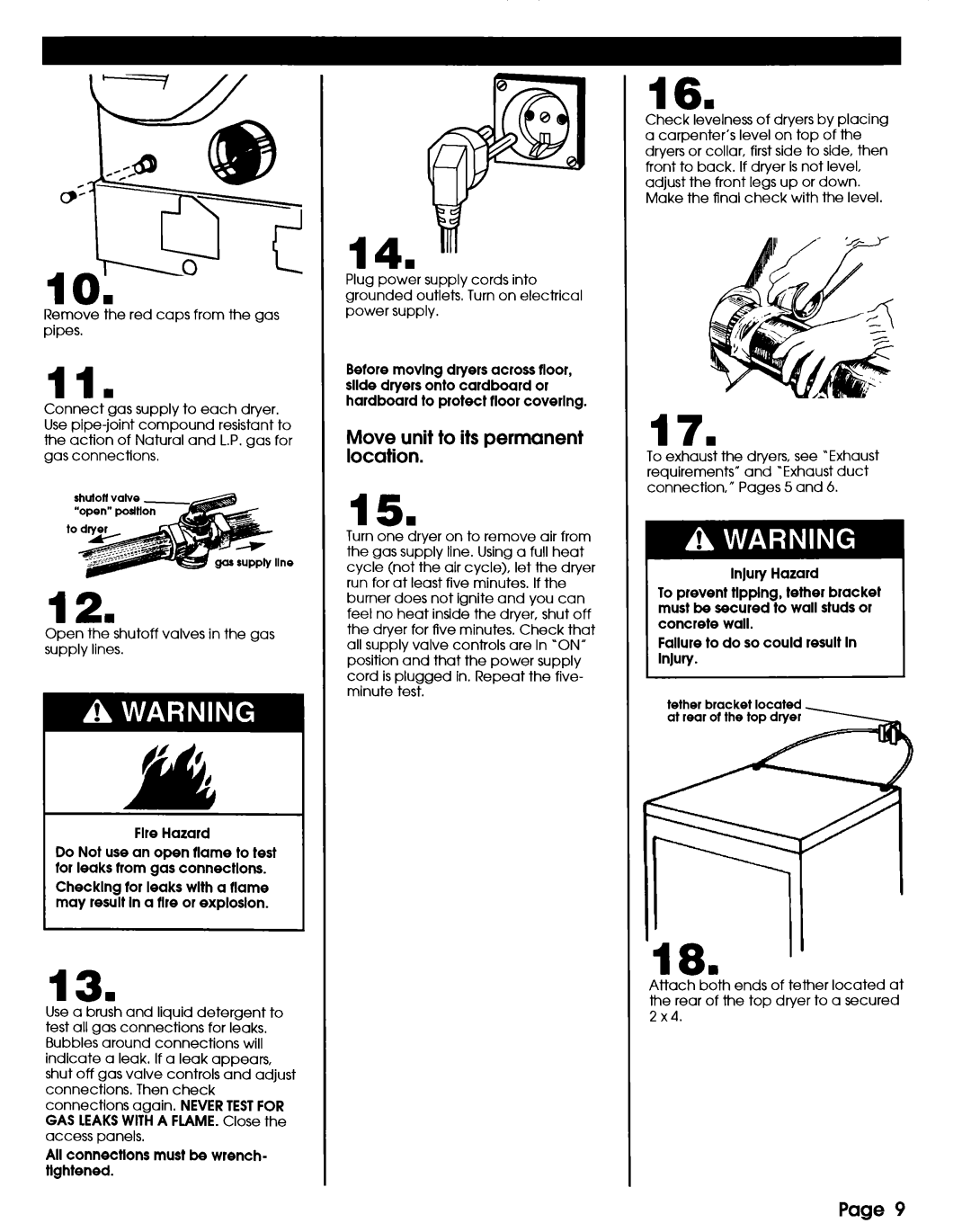

Remove the red caps from the gas pipes.

11.

Connect gas supply to each dryer. Use

12.

Open the shutoff valves in the gas supply lines.

Fire Hazard

Do Not use an open flame to test tar leaks from gas connectlons.

Checking for leaks wlth a flame may result In a tire or explosion.

13.

Use a brush and liquid detergent to test all gas connections for leaks. Bubbles around connections will indicate a leak. If a leak appears, shut off gas valve controls and adjust connections. Then check connections again. NEVERTESTFOR GAS LEAKSWITHA FLAME. Close the access panels.

All connectlons must be wrench- tightened.

Plug power supply cords into grounded outlets, Turn on electrical power supply.

Betore movlng dryers across floor, slide dryers onto cardboard or hardboard to protect rloor coverlng.

Move unit to its permanent location.

15.

Turn one dryer on to remove air from the gas supply line. Using a full heat cycle (not the air cycle), let the dryer run for at least five minutes. If the burner does not ignite and you can feel no heat inside the dryer, shut off the dryer for five minutes. Check that all supply valve controls are In “ON” position and that the power supply cord is plugged in. Repeat the five- minute test.

16 n

Check levelness of dryers by placing a carpenter’s level on top of the dryers or collar, first side to side, then front to back. If dryer Is not level. adjust the front legs up or down. Make the final check with the level.

17.

To exhaust the dryers, see “Exhaust requirements” and “Exhaust duct

connection,” Pages 5 and 6.

Injury Hazard

To prevent tlpplng, tether bracket must be secured to wall studs or concrete wall.

Failure to do so could result In InJury.

tether bracket lo at rear of the top

Attach both ends of tether located at the rear of the top, drver, to a secured

2 x4.

Page 9