Exhaust requirements

Fire Hazard

Do Not use

Do Not use exhaust hoods wlth metal latches.

Check that exhaust system Is not longer than specltled. Exhaust system longer than speclfled will:

-Accumulate Ilnt.

-Shorten the llfe ot the dryer.

-Reduce the performance, resulting In longer drylng times and Increased energy usage.

Failure to r0ii0w specltlcatlons may result In a tire.

Do Not exhaust dryers Into a chimney, turnace cold alr duct, alilc or crawl space, or any other duct used ror ventlng.

Clean the exhaust system every other year.

Do Not Install tlexlble duct In enclosed walls, celllngs or floors.

Accumulated lint could result In a fire or cause moisture damage. Exhaust dryers outslde to prevent exposure to substances In gas tuels and combustion which may be harmful to your health.

The moisture and llnt Indoors may cause:

-FIREHAZARDtram llnt collected In dryer.

-Moisture damage to woodwork, furniture, palnt, wallpaper, carpet, etc.

-Housecleanlng problems and possible health problems.

Failure to tallow these lnstructlons could result In a tlre or Inlury.

ixhaust materials are not supplled.

It uslng an exlstlng exhaust system, clean llnt from entlre length ot exhaust system. Make sure exhaust hood Is not plugged wlth Ilnt.

The exhaust system should be Inspected and cleaned yearly.

Replace any vlnyl or metalllzed plastic toll exhaust duct wlth rlgld metal or tlexlble metal duct.

Use duct tape to seal all joints. Do Not use screws to secure duct.

(tour- | exhaust | air tlow | ||

Inch) | metal | better | good | |

exhaust | duct is | |||

required. | Plan |

|

| |

installation to |

|

| ||

use the | fewest |

|

| |

number | of elbows |

|

| |

and | turns, | i?zJ |

| |

|

|

|

| |

Metal tlexlble duct must be fully extended and supported when the dryers are in final position, DO NOT KINK OR CRUSH THE DUCT. The metal flexible duct must be completely open to allow adequate exhaust air to flow.

Allow as much room as possible when using elbows or making turns. Bend duct gradually to avoid kinking. Remove excess flexible duct to avoid sagging and kinking that may cause reduced airflow.

The external exhaust ducts can be routed straight out the back of the dryers. Kits are available to convert the external exhaust duct to be routed right, left or through the bottom (See Page 6). Product dimensions and recessed area requirements are given on Page 7.

Slde or bottom exhaust: The maximum length of the exhaust system through the side or bottom is

4.9m (16 feet) wlth two external elbows and hood.

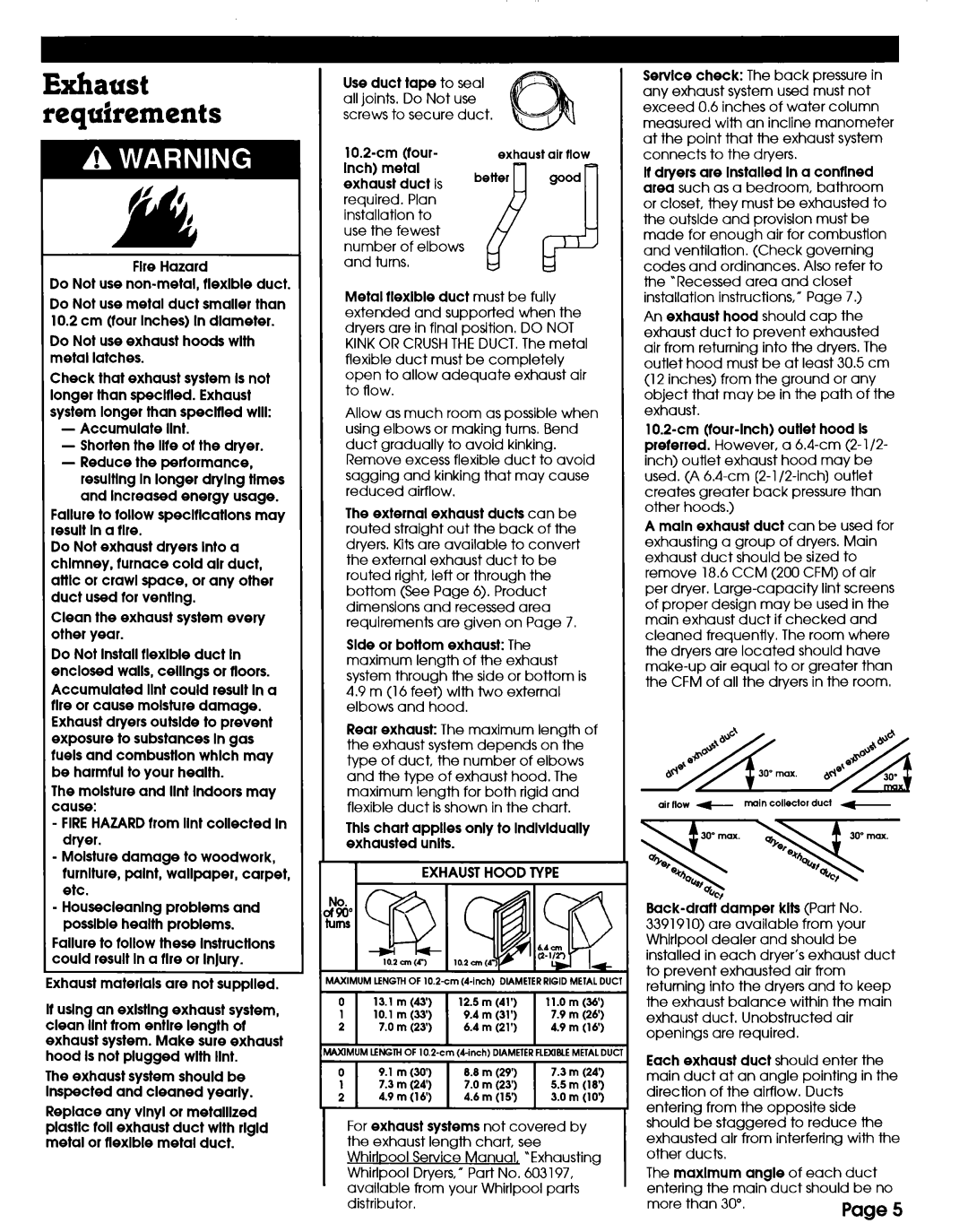

Rear exhaust: The maximum length of the exhaust system depends on the type of duct, the number of elbows and the type of exhaust hood. The maximum length for both rigid and flexible duct is shown in the chart.

Thls chart applies only to lndlvldually exhausted unlts.

I | EXHAUSTHOOD TYPE |

E!$i29;s

IQ2all

WIMUM LENGTH OF 10.2~cm

0 | 13.1m | (43’) | 12.5m (41’) | 11.0m | (36’) | ||

1 | 10.1m | (33’) | 9.4 | m (31’) | 7.9 | m (26’) | |

2 | 7.0 m (23’) | 6.4 | m (21’) | 4.9 | m (16’) | ||

I |

|

| I |

| I |

|

|

AXIMUM IfNGiH OF 10.2~cm

0 | 9.1 m (JO’) | 8.8 | m (29’) | 7.3 | m (24’) | |

1 | 7.3 | m (24’) | 7.0 | m (23’) | 5.5 m (18’) | |

2 | 4.9 | m (16’) | 4.6 | m (15’) | 3.0 | m (10’) |

For exhaust systems not covered by the exhaust length chart, see WhirtDool Service Manual, “Exhausting Whirlpool Dryers,” Part No. 603197, available from your Whirlpool parts distributor.

Service check: The back pressure in any exhaust system used must not exceed 0.6 inches of water column measured with an incline manometer at the point that the exhaust system connects to the dryers.

If dryers are Installed In a conflned area such as a bedroom, bathroom or closet, they must be exhausted to the outslde and provislon must be made for enough air for combustion and ventilation. (Check governing codes and ordinances. Also refer to the “Recessed area and closet installation instructions,” Page 7.)

An exhaust hood should cap the exhaust duct to prevent exhausted air from returning into the dryers. The outlet hood must be at least 30.5 cm (12 inches) from the ground or any object that may be in the path of the exhaust.

A maln exhaust duct can be used for exhausting a group of dryers. Main exhaust duct should be sized to remove 18.6 CCM (200 CFM) of air

per dryer.

airflow | - | maincolleciorducl | - |

Each exhaust duct should enter the main duct at an angle pointing in the direction of the airflow. Ducts entering from the opposite side should be staggered to reduce the exhausted alr from interfering with the other ducts,

The maxlmum angle of | each | duct |

entering the main duct | should | be no |

more than 30”. |

| Page 5 |

|

|