COMPONENT TESTING

Before testing any of the components, per- form the following checks:

•The most common cause for control failure is corrosion on connectors. Therefore, dis- connecting and reconnecting wires will be necessary throughout test procedures.

•All tests/checks should be made with a VOM or DVM having a sensitivity of 20,000

•Check all connections before replacing components, looking for broken or loose wires, failed terminals, or wires not pressed into connectors far enough.

•Resistance checks must be made with power cord unplugged from outlet, and with wiring harness or connectors discon-

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

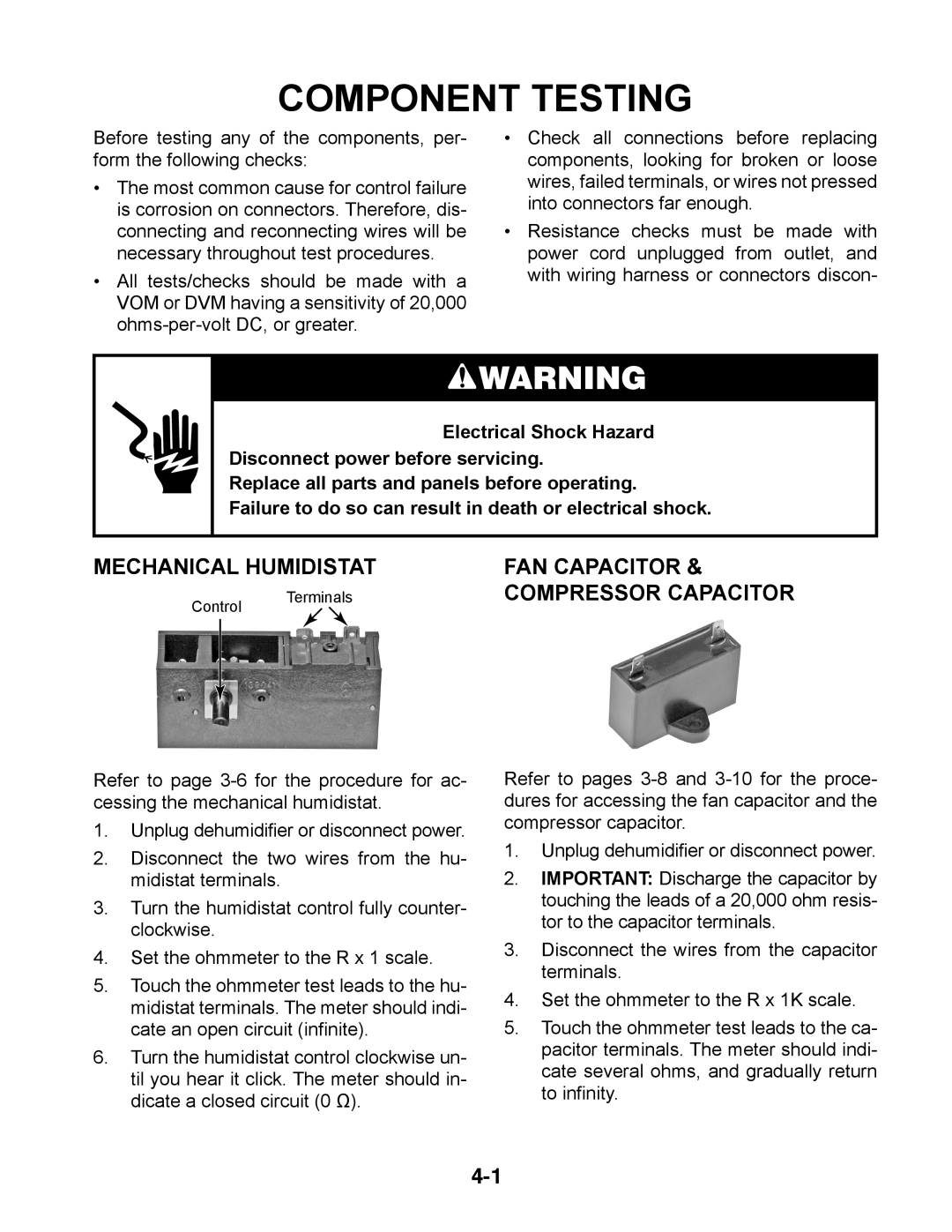

MECHANICAL HUMIDISTAT | FAN CAPACITOR & | |

Control | Terminals | COMPRESSOR CAPACITOR |

|

| |

Refer to page

1.Unplug dehumidifier or disconnect power.

2.Disconnect the two wires from the hu- midistat terminals.

3.Turn the humidistat control fully counter- clockwise.

4.Set the ohmmeter to the R x 1 scale.

5.Touch the ohmmeter test leads to the hu- midistat terminals. The meter should indi- cate an open circuit (infinite).

6.Turn the humidistat control clockwise un- til you hear it click. The meter should in- dicate a closed circuit (0 Ω).

Refer to pages

1.Unplug dehumidifier or disconnect power.

2.IMPORTANT: Discharge the capacitor by touching the leads of a 20,000 ohm resis- tor to the capacitor terminals.

3.Disconnect the wires from the capacitor terminals.

4.Set the ohmmeter to the R x 1K scale.

5.Touch the ohmmeter test leads to the ca- pacitor terminals. The meter should indi- cate several ohms, and gradually return to infinity.