Blade Guide Bearing Adjustment

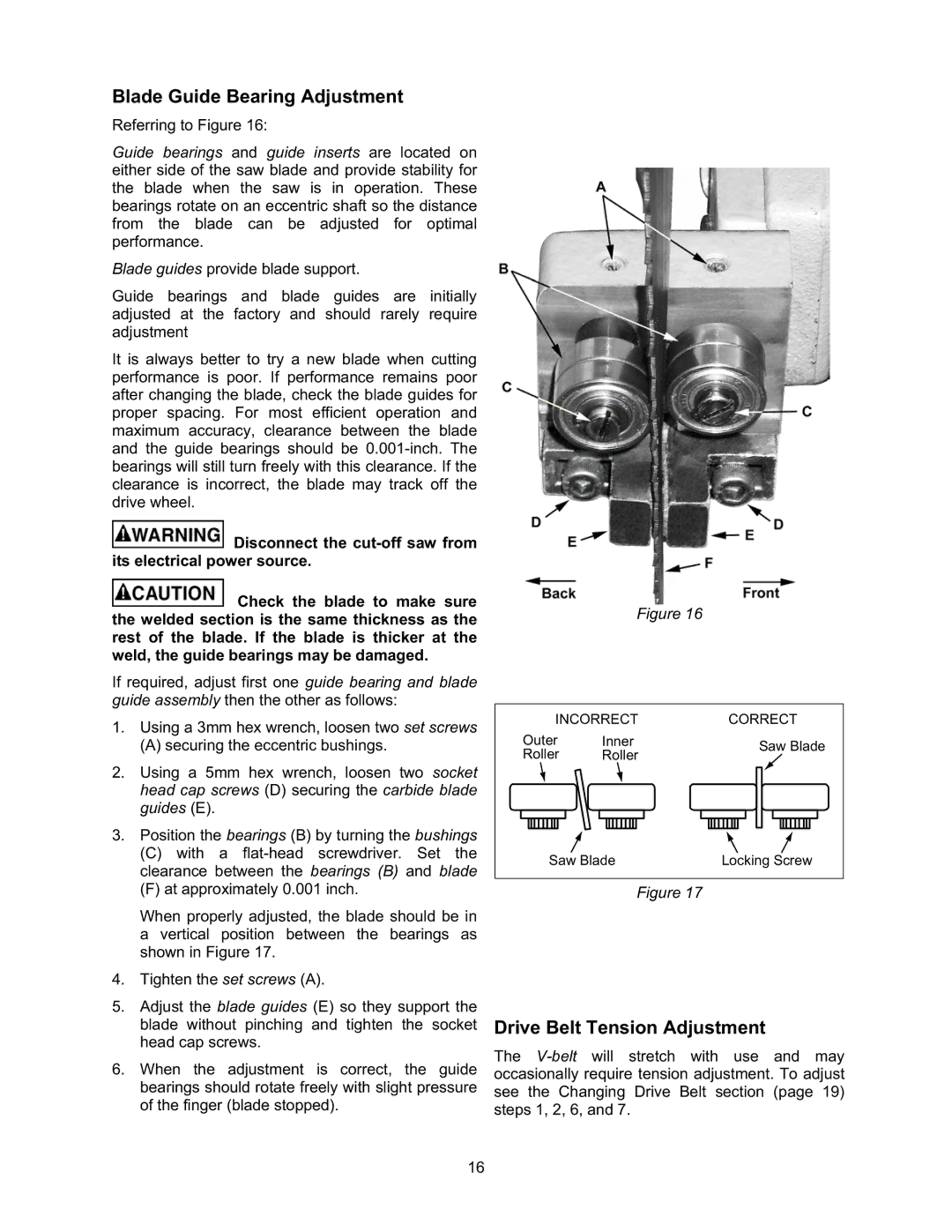

Referring to Figure 16:

Guide bearings and guide inserts are located on either side of the saw blade and provide stability for the blade when the saw is in operation. These bearings rotate on an eccentric shaft so the distance from the blade can be adjusted for optimal performance.

Blade guides provide blade support.

Guide bearings and blade guides are initially adjusted at the factory and should rarely require adjustment

It is always better to try a new blade when cutting performance is poor. If performance remains poor after changing the blade, check the blade guides for proper spacing. For most efficient operation and maximum accuracy, clearance between the blade and the guide bearings should be

![]() Disconnect the

Disconnect the

![]() Check the blade to make sure the welded section is the same thickness as the rest of the blade. If the blade is thicker at the weld, the guide bearings may be damaged.

Check the blade to make sure the welded section is the same thickness as the rest of the blade. If the blade is thicker at the weld, the guide bearings may be damaged.

If required, adjust first one guide bearing and blade guide assembly then the other as follows:

1.Using a 3mm hex wrench, loosen two set screws

(A)securing the eccentric bushings.

2.Using a 5mm hex wrench, loosen two socket head cap screws (D) securing the carbide blade guides (E).

3.Position the bearings (B) by turning the bushings

(C)with a

(F)at approximately 0.001 inch.

When properly adjusted, the blade should be in a vertical position between the bearings as shown in Figure 17.

4.Tighten the set screws (A).

5.Adjust the blade guides (E) so they support the blade without pinching and tighten the socket head cap screws.

6.When the adjustment is correct, the guide bearings should rotate freely with slight pressure of the finger (blade stopped).

Figure 16

INCORRECT | CORRECT | ||

Outer | Inner | Saw Blade | |

Roller | Roller | ||

| |||

Saw Blade | Locking Screw | ||

Figure 17

Drive Belt Tension Adjustment

The

16