Coolant Flow and Nozzle Position

![]() The coolant pump must be submerged before operating to prevent damage to the pump.

The coolant pump must be submerged before operating to prevent damage to the pump.

Adjust the coolant flow

The coolant flow can be stopped in two ways:

by the coolant selector switch (A, Fig. 4) on the control box (the preferred method)

by closing the

Note: The coolant pump is

Setting the Work Stop

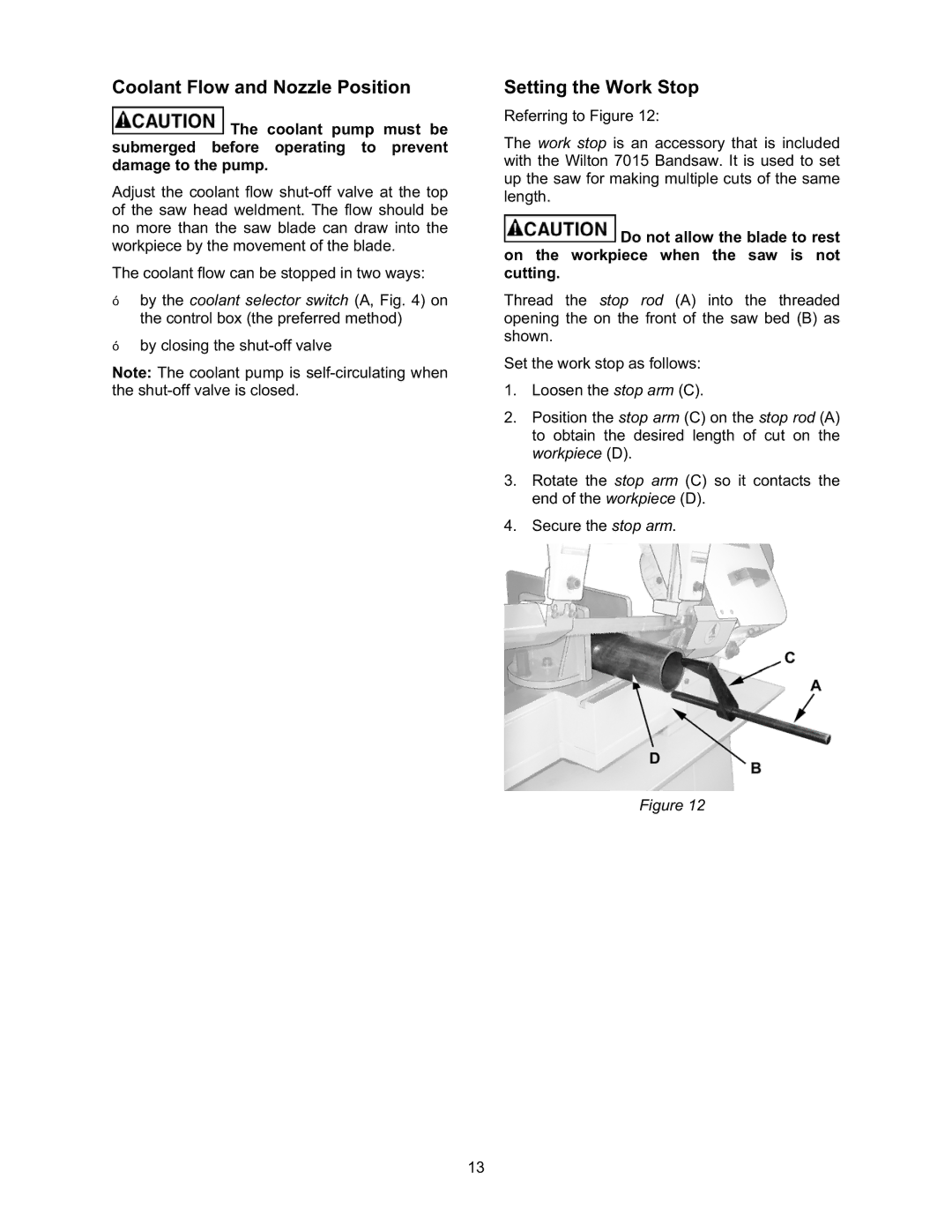

Referring to Figure 12:

The work stop is an accessory that is included with the Wilton 7015 Bandsaw. It is used to set up the saw for making multiple cuts of the same length.

Do not allow the blade to rest on the workpiece when the saw is not cutting.

Thread the stop rod (A) into the threaded opening the on the front of the saw bed (B) as shown.

Set the work stop as follows:

1.Loosen the stop arm (C).

2.Position the stop arm (C) on the stop rod (A) to obtain the desired length of cut on the workpiece (D).

3.Rotate the stop arm (C) so it contacts the end of the workpiece (D).

4.Secure the stop arm.

Figure 12

13