12

breaker in the branch circuit.

2.Move the upper blade guide assembly to the very top of its travel.

3.Make sure the blade is straight, and fully tensioned. (A damaged or worn blade may provide a poor reference surface for squaring the table.)

4.Loosen the table lock knobs and hold the table firmly against its positive leveling stop.

6.Using a machinist’s square, check to make sure the table is 90 degrees to the blade.

USING LEATHER PROTECTIVE GLOVES, turn the upper drive wheel to check the squareness at a minimum of three points on the blade

7.If the table is not level, unlock the lock nut on the table leveling bolt.

8.Turn the leveling bolt as required to make the table square to the blade.

9.Lock the leveling bolt lock nut and recheck the table level. When the table is level...

10.Lock the table lock knobs securely and recheck for level. Adjust as necessary until the table is level while everything is tightened to working tightness.

11.With everything locked down, look at the pointer for the angle gauge. It should be exactly on the zero mark of the gauge (Figure 12). If not, loosen the pointer screw, adjust the pointer until it is on zero, then tighten the pointer screw while holding the pointer se- curely in position on zero.

Adjusting Miter Gauge Slot Parallelism

The miter slot should be parallel to the side of the blade. If the saw is not cutting straight when using the miter gauge, the miter slot may not be parallel.

1.Put a straight edge against the blade. Make sure to position the blade so tooth offset does not affect the straight edge.

2. Measure from both ends of the miter slot to the

straight edge.3. If the measurements are not equal at both ends of the slot, loosen six bolts securing the table to the table trunnions (see Figures 12 and 13.)

4.Adjust the table until it is parallel with the blade.

5.Tighten the trunnion attaching bolts.

Adjusting Blade Speed (Models 8201/8203)

Figure 6 on page 9 provides blade speeds for various materials. To adjust the blade speed, change the clutch position of the clutch (in or out) and the position of the drive belt on the pulleys on the motor and reduction gearbox shafts.

Adjusting Blade Speed (Models 8201VS/8203VS)

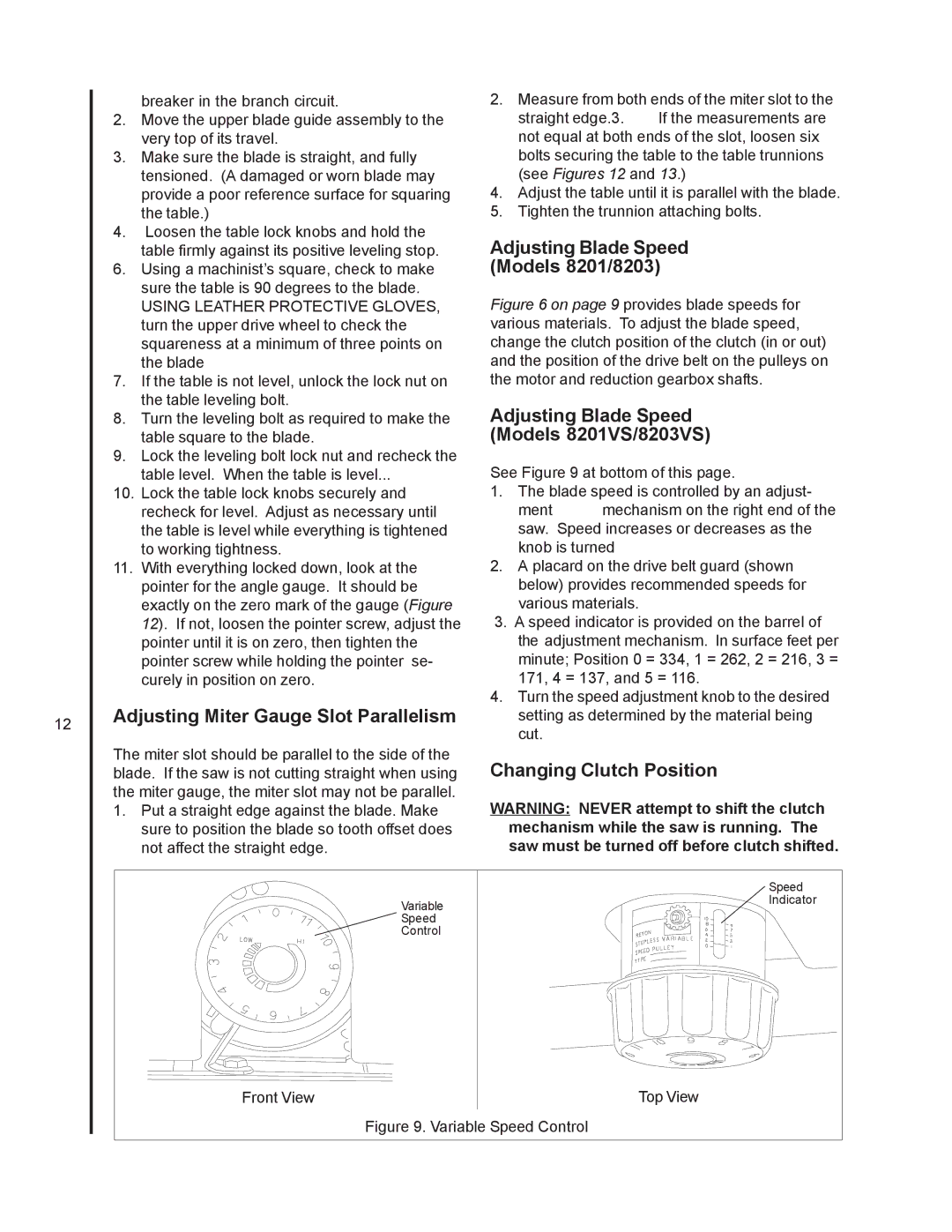

See Figure 9 at bottom of this page.

1. The blade speed is controlled by an adjust-

ment mechanism on the right end of the saw. Speed increases or decreases as the knob is turned

2.A placard on the drive belt guard (shown below) provides recommended speeds for various materials.

3.A speed indicator is provided on the barrel of the adjustment mechanism. In surface feet per minute; Position 0 = 334, 1 = 262, 2 = 216, 3 = 171, 4 = 137, and 5 = 116.

4.Turn the speed adjustment knob to the desired setting as determined by the material being cut.

Changing Clutch Position

WARNING: NEVER attempt to shift the clutch mechanism while the saw is running. The saw must be turned off before clutch shifted.

| Speed |

Variable | Indicator |

Speed |

|

Control |

|

Front View | Top View |