1.Turn the main switch to off.

2.Pull the door open on the pulley case.

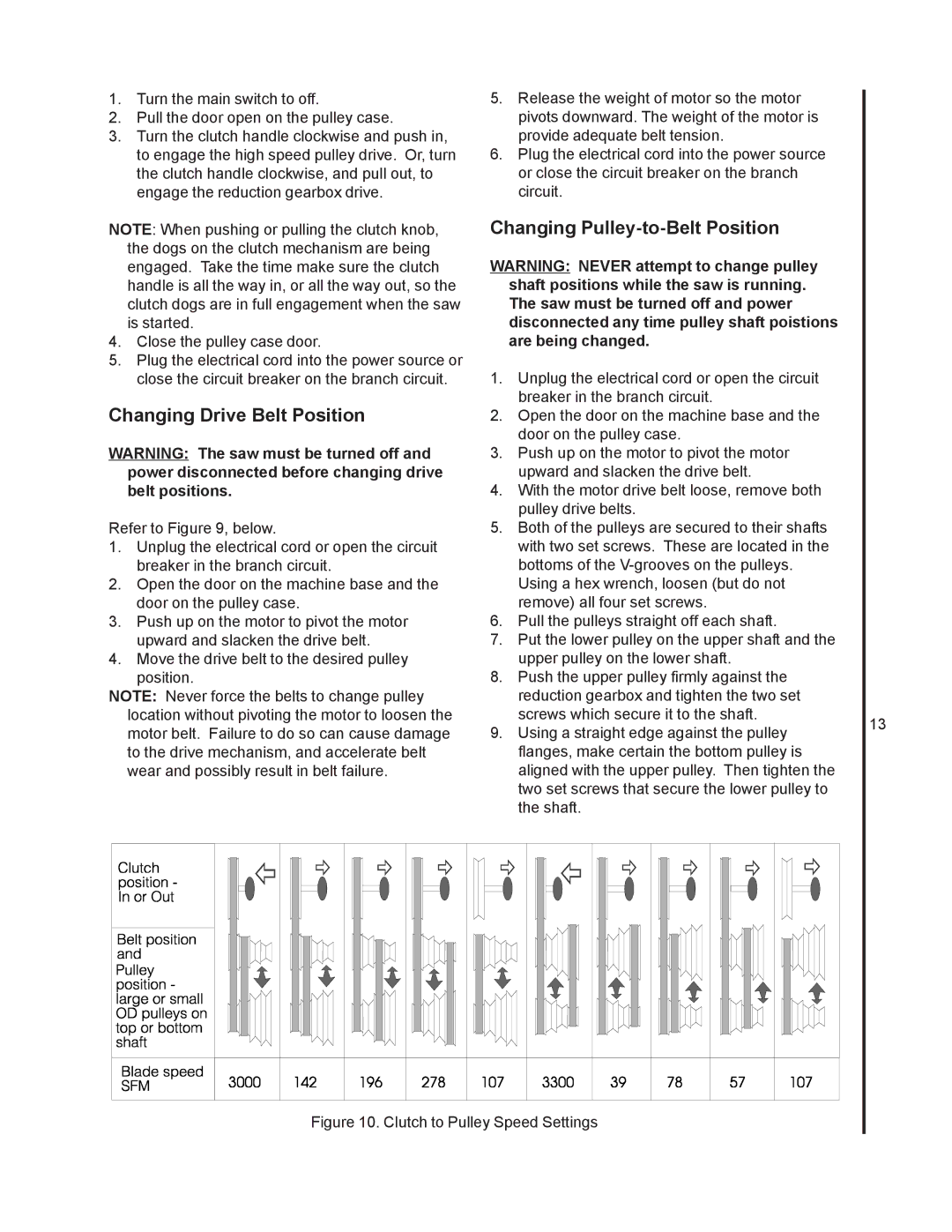

3.Turn the clutch handle clockwise and push in, to engage the high speed pulley drive. Or, turn the clutch handle clockwise, and pull out, to engage the reduction gearbox drive.

NOTE: When pushing or pulling the clutch knob, the dogs on the clutch mechanism are being engaged. Take the time make sure the clutch handle is all the way in, or all the way out, so the clutch dogs are in full engagement when the saw is started.

4.Close the pulley case door.

5.Plug the electrical cord into the power source or close the circuit breaker on the branch circuit.

Changing Drive Belt Position

WARNING: The saw must be turned off and power disconnected before changing drive belt positions.

Refer to Figure 9, below.

1.Unplug the electrical cord or open the circuit breaker in the branch circuit.

2.Open the door on the machine base and the door on the pulley case.

3.Push up on the motor to pivot the motor upward and slacken the drive belt.

4.Move the drive belt to the desired pulley position.

NOTE: Never force the belts to change pulley location without pivoting the motor to loosen the motor belt. Failure to do so can cause damage to the drive mechanism, and accelerate belt wear and possibly result in belt failure.

5.Release the weight of motor so the motor pivots downward. The weight of the motor is provide adequate belt tension.

6.Plug the electrical cord into the power source or close the circuit breaker on the branch circuit.

Changing Pulley-to-Belt Position

WARNING: NEVER attempt to change pulley shaft positions while the saw is running. The saw must be turned off and power disconnected any time pulley shaft poistions are being changed.

1.Unplug the electrical cord or open the circuit breaker in the branch circuit.

2.Open the door on the machine base and the door on the pulley case.

3.Push up on the motor to pivot the motor upward and slacken the drive belt.

4.With the motor drive belt loose, remove both pulley drive belts.

5.Both of the pulleys are secured to their shafts with two set screws. These are located in the bottoms of the

Using a hex wrench, loosen (but do not remove) all four set screws.

6.Pull the pulleys straight off each shaft.

7.Put the lower pulley on the upper shaft and the upper pulley on the lower shaft.

8.Push the upper pulley firmly against the reduction gearbox and tighten the two set screws which secure it to the shaft.

9.Using a straight edge against the pulley flanges, make certain the bottom pulley is aligned with the upper pulley. Then tighten the two set screws that secure the lower pulley to the shaft.

13