16

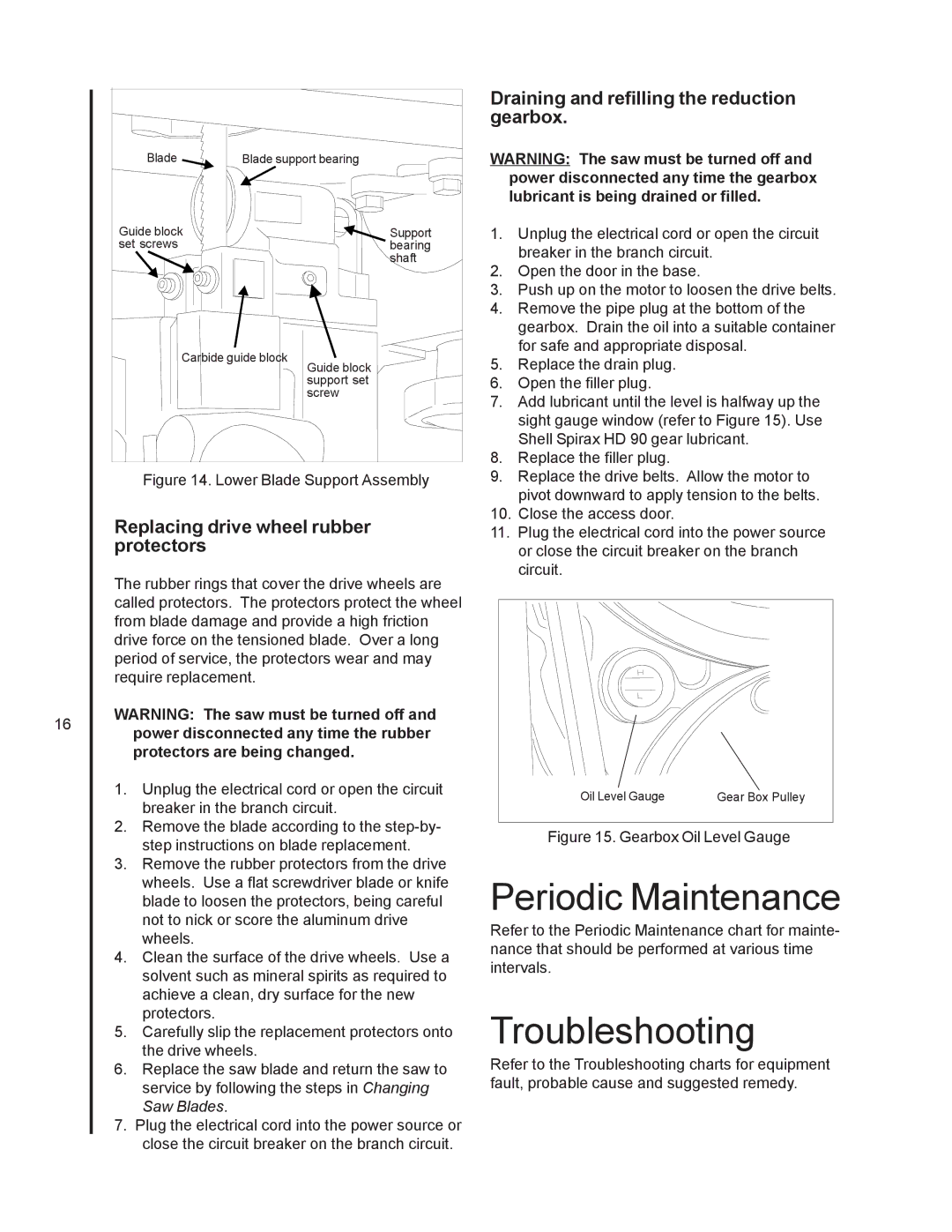

Blade | Blade support bearing |

Guide block | Support |

set screws | bearing |

| shaft |

Carbide guide block

Guide block support set screw

Figure 14. Lower Blade Support Assembly

Replacing drive wheel rubber protectors

The rubber rings that cover the drive wheels are called protectors. The protectors protect the wheel from blade damage and provide a high friction drive force on the tensioned blade. Over a long period of service, the protectors wear and may require replacement.

WARNING: The saw must be turned off and power disconnected any time the rubber protectors are being changed.

1.Unplug the electrical cord or open the circuit breaker in the branch circuit.

2.Remove the blade according to the

3.Remove the rubber protectors from the drive wheels. Use a flat screwdriver blade or knife blade to loosen the protectors, being careful not to nick or score the aluminum drive wheels.

4.Clean the surface of the drive wheels. Use a solvent such as mineral spirits as required to achieve a clean, dry surface for the new protectors.

5.Carefully slip the replacement protectors onto the drive wheels.

6.Replace the saw blade and return the saw to service by following the steps in Changing Saw Blades.

7.Plug the electrical cord into the power source or close the circuit breaker on the branch circuit.

Draining and refilling the reduction gearbox.

WARNING: The saw must be turned off and power disconnected any time the gearbox lubricant is being drained or filled.

1.Unplug the electrical cord or open the circuit breaker in the branch circuit.

2.Open the door in the base.

3.Push up on the motor to loosen the drive belts.

4.Remove the pipe plug at the bottom of the gearbox. Drain the oil into a suitable container for safe and appropriate disposal.

5.Replace the drain plug.

6.Open the filler plug.

7.Add lubricant until the level is halfway up the sight gauge window (refer to Figure 15). Use Shell Spirax HD 90 gear lubricant.

8.Replace the filler plug.

9.Replace the drive belts. Allow the motor to pivot downward to apply tension to the belts.

10.Close the access door.

11.Plug the electrical cord into the power source or close the circuit breaker on the branch circuit.

Oil Level Gauge | Gear Box Pulley |

Figure 15. Gearbox Oil Level Gauge

Periodic Maintenance

Refer to the Periodic Maintenance chart for mainte- nance that should be performed at various time intervals.

Troubleshooting

Refer to the Troubleshooting charts for equipment fault, probable cause and suggested remedy.