18

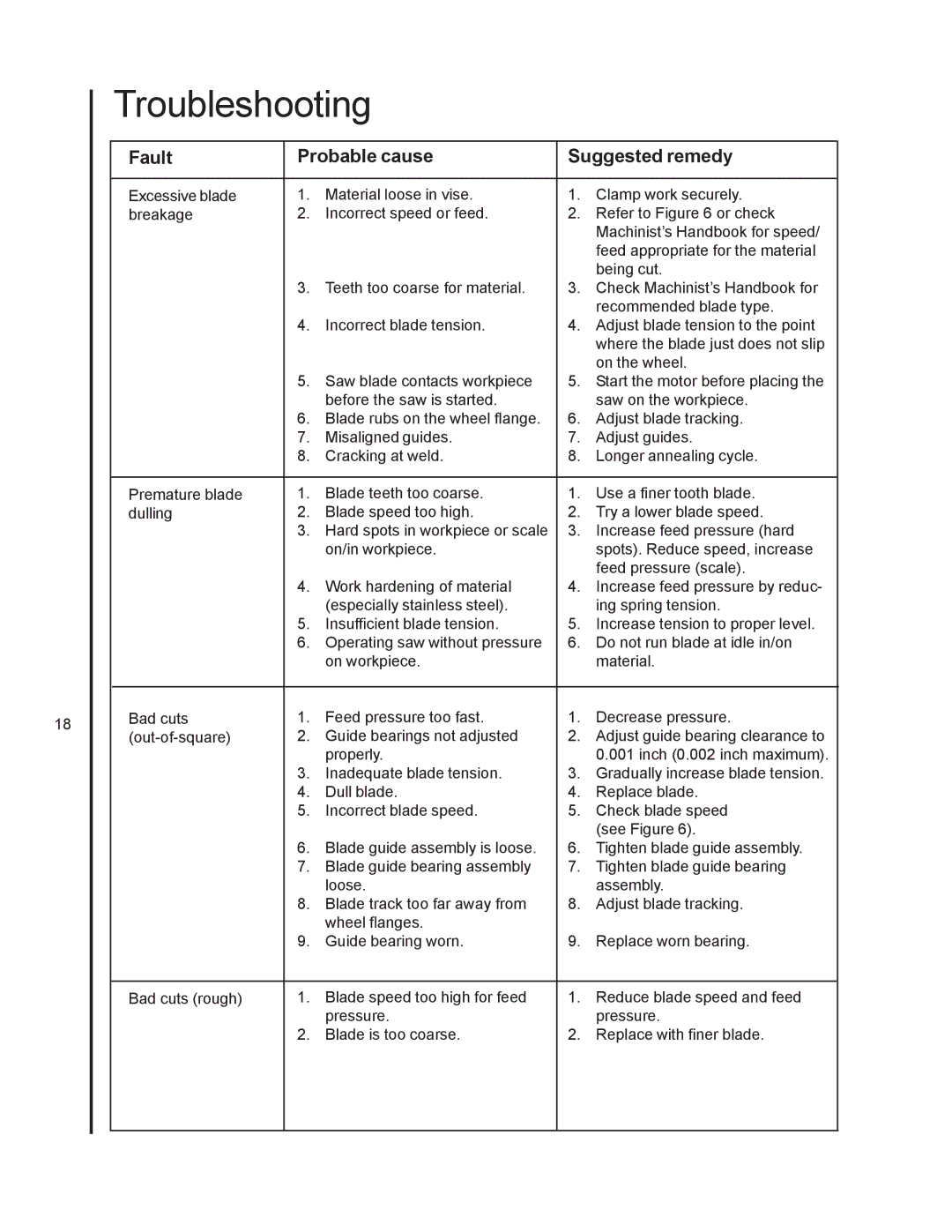

Troubleshooting

Fault | Probable cause | Suggested remedy | ||

|

|

|

|

|

Excessive blade | 1. | Material loose in vise. | 1. | Clamp work securely. |

breakage | 2. | Incorrect speed or feed. | 2. | Refer to Figure 6 or check |

|

|

|

| Machinist’s Handbook for speed/ |

|

|

|

| feed appropriate for the material |

|

|

|

| being cut. |

| 3. | Teeth too coarse for material. | 3. | Check Machinist’s Handbook for |

|

|

|

| recommended blade type. |

| 4. | Incorrect blade tension. | 4. | Adjust blade tension to the point |

|

|

|

| where the blade just does not slip |

|

|

|

| on the wheel. |

| 5. | Saw blade contacts workpiece | 5. | Start the motor before placing the |

|

| before the saw is started. |

| saw on the workpiece. |

| 6. | Blade rubs on the wheel flange. | 6. | Adjust blade tracking. |

| 7. | Misaligned guides. | 7. | Adjust guides. |

| 8. | Cracking at weld. | 8. | Longer annealing cycle. |

|

|

|

|

|

Premature blade | 1. | Blade teeth too coarse. | 1. | Use a finer tooth blade. |

dulling | 2. | Blade speed too high. | 2. | Try a lower blade speed. |

| 3. | Hard spots in workpiece or scale | 3. | Increase feed pressure (hard |

|

| on/in workpiece. |

| spots). Reduce speed, increase |

|

|

|

| feed pressure (scale). |

| 4. | Work hardening of material | 4. | Increase feed pressure by reduc- |

|

| (especially stainless steel). |

| ing spring tension. |

| 5. | Insufficient blade tension. | 5. | Increase tension to proper level. |

| 6. | Operating saw without pressure | 6. | Do not run blade at idle in/on |

|

| on workpiece. |

| material. |

|

|

|

|

|

Bad cuts | 1. | Feed pressure too fast. | 1. | Decrease pressure. |

2. | Guide bearings not adjusted | 2. | Adjust guide bearing clearance to | |

|

| properly. |

| 0.001 inch (0.002 inch maximum). |

| 3. | Inadequate blade tension. | 3. | Gradually increase blade tension. |

| 4. | Dull blade. | 4. | Replace blade. |

| 5. | Incorrect blade speed. | 5. | Check blade speed |

|

|

|

| (see Figure 6). |

| 6. | Blade guide assembly is loose. | 6. | Tighten blade guide assembly. |

| 7. | Blade guide bearing assembly | 7. | Tighten blade guide bearing |

|

| loose. |

| assembly. |

| 8. | Blade track too far away from | 8. | Adjust blade tracking. |

|

| wheel flanges. |

|

|

| 9. | Guide bearing worn. | 9. | Replace worn bearing. |

|

|

|

|

|

Bad cuts (rough) | 1. | Blade speed too high for feed | 1. | Reduce blade speed and feed |

|

| pressure. |

| pressure. |

| 2. | Blade is too coarse. | 2. | Replace with finer blade. |

|

|

|

|

|