14

10.Install the belts as required (refer to Figure 10).

11.Release the weight of motor so the motor pivots downward. The weight of the motor will provide adequate belt tension.

12.The weight of the motor should provide sufficient tension so the the middle of the small drive belt is displaced approximately the thickness of the belt. (The high speed belt is adjusted at the same time as the smaller belt.)

13.Set the drive clutch to the desired position (IN or OUT).

14.Close the access doors.

15.Plug the electrical cord into the power source or close the circuit breaker on the branch circuit.

Using Miter System

A miter gauge is provided with the band saw. The miter gauge slips into a slot in the face of the work table. The miter gauge can be adjusted from 0 to 45 degrees.

Adjust the miter gauge as follows:

1.Loosen the clamping screw on the miter gauge.

2.Adjust to desired angle.

3.Tighten the clamping screw.

Using Rip Fence

1.Unlock the fence by loosening the lock knob (ref. 7) and handle (ref. 10.)

2.Slide the fence on its guides until it is the required distance from the blade.

3.Tighten the lock knob and handle, slightly.

4.Using a machinist’s square, measure the distance between the edge of the miter slot and both the front and rear of the rip fence. Adjust so both distances are equal.

5.Check the

6.Tighten the fence firmly using the lock knob and handle.

Using the Dust Control Chute

On the lower side of the table, below the cutting position of the blade, is a plastic tube which can be attached to a shop vacuum, or to a shop dust control system. The dust control chute can be seen in several of the figures used to illustrate the operation of the saw.

Maintenance

This section contains periodic maintenance recommendations and maintenance procedures.

Changing Saw Blade

WARNING: The saw must be turned off and power disconnected any time saw blades are being changed.

1.Unplug the electrical cord or open the circuit breaker in the branch circuit.

2.Pull open both upper and lower drive wheel guards (refer to Figure 1).

3.Release blade tension completely by turning the tension handle fully counterclockwise.

4.Remove table leveling pin. The pin has a tight push fit in its slot; it is not threaded. (Refer to Figure 13.

5.Use a screwdriver to pop out the table insert.

6.Loosen the set screws that lock the guide blocks. Move the guide blocks outward. Then turn the

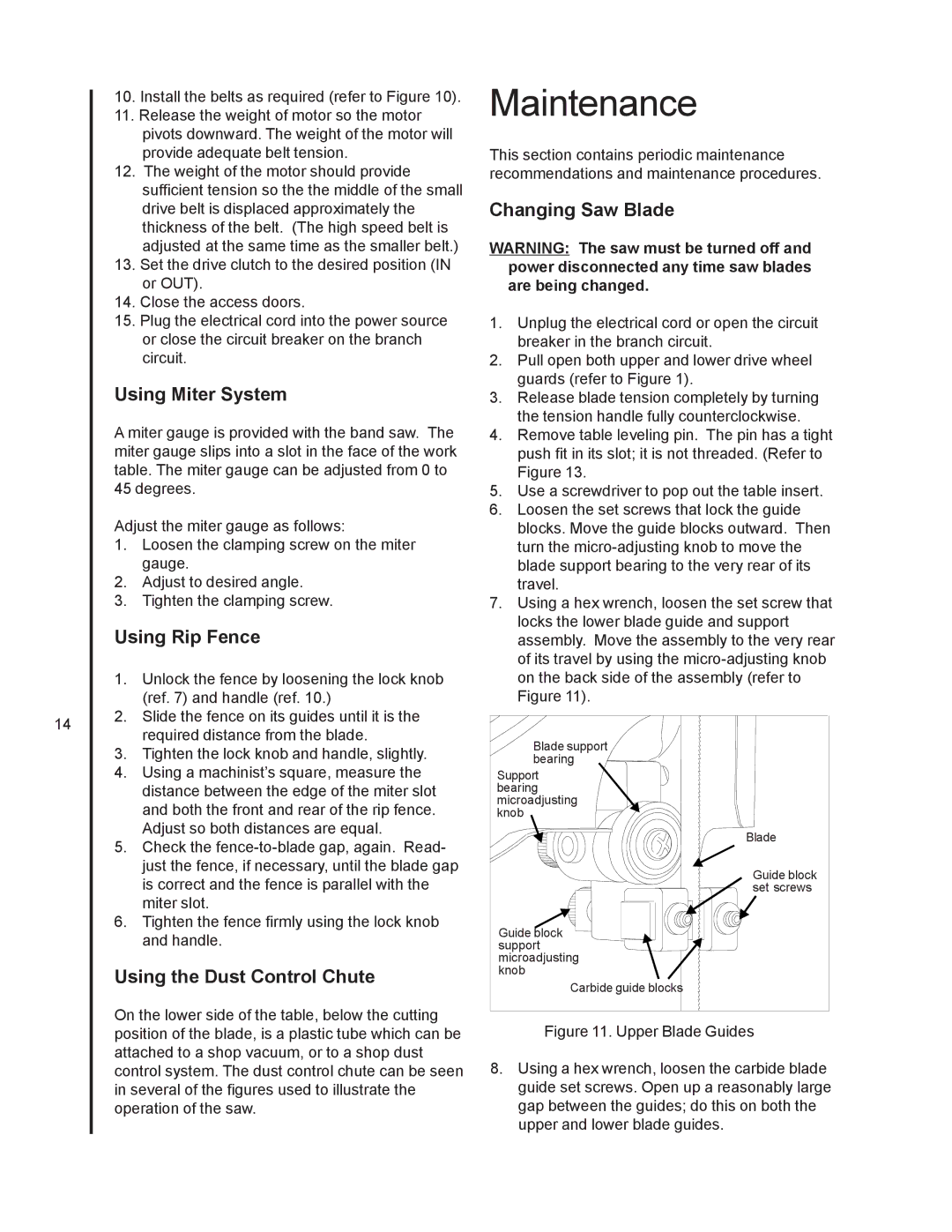

7.Using a hex wrench, loosen the set screw that locks the lower blade guide and support assembly. Move the assembly to the very rear of its travel by using the

Blade support bearing

Support bearing microadjusting knob

Blade

Guide block set screws

Guide block support microadjusting knob

Carbide guide blocks