10

Operating Instructions

Operating Controls

START/STOP Switch

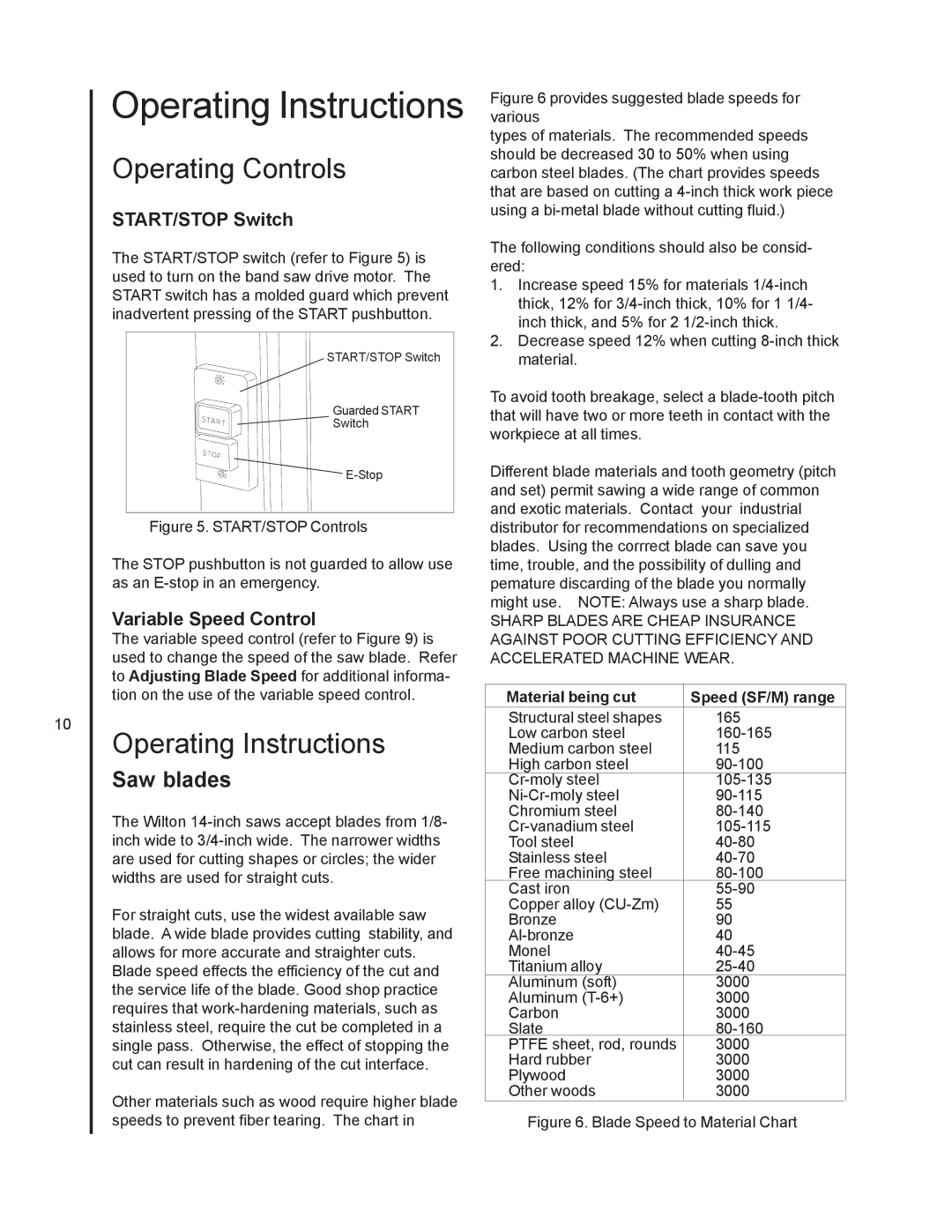

The START/STOP switch (refer to Figure 5) is used to turn on the band saw drive motor. The START switch has a molded guard which prevent inadvertent pressing of the START pushbutton.

START/STOP Switch

Guarded START

Switch

Figure 5. START/STOP Controls

The STOP pushbutton is not guarded to allow use as an E-stop in an emergency.

Variable Speed Control

The variable speed control (refer to Figure 9) is used to change the speed of the saw blade. Refer to Adjusting Blade Speed for additional informa- tion on the use of the variable speed control.

Operating Instructions

Saw blades

The Wilton

For straight cuts, use the widest available saw blade. A wide blade provides cutting stability, and allows for more accurate and straighter cuts. Blade speed effects the efficiency of the cut and the service life of the blade. Good shop practice requires that

Other materials such as wood require higher blade speeds to prevent fiber tearing. The chart in

Figure 6 provides suggested blade speeds for various

types of materials. The recommended speeds should be decreased 30 to 50% when using carbon steel blades. (The chart provides speeds that are based on cutting a 4-inch thick work piece using a bi-metal blade without cutting fluid.)

The following conditions should also be consid- ered:

1.Increase speed 15% for materials 1/4-inch thick, 12% for 3/4-inch thick, 10% for 1 1/4- inch thick, and 5% for 2 1/2-inch thick.

2.Decrease speed 12% when cutting 8-inch thick material.

To avoid tooth breakage, select a blade-tooth pitch that will have two or more teeth in contact with the workpiece at all times.

Different blade materials and tooth geometry (pitch and set) permit sawing a wide range of common and exotic materials. Contact your industrial distributor for recommendations on specialized blades. Using the corrrect blade can save you time, trouble, and the possibility of dulling and pemature discarding of the blade you normally might use. NOTE: Always use a sharp blade.

SHARP BLADES ARE CHEAP INSURANCE AGAINST POOR CUTTING EFFICIENCY AND ACCELERATED MACHINE WEAR.

Material being cut | Speed (SF/M) range |

Structural steel shapes | 165 |

Low carbon steel | |

Medium carbon steel | 115 |

High carbon steel | |

Chromium steel | |

Tool steel | |

Stainless steel | |

Free machining steel | |

Cast iron | |

Copper alloy | 55 |

Bronze | 90 |

40 | |

Monel | |

Titanium alloy | |

Aluminum (soft) | 3000 |

Aluminum | 3000 |

Carbon | 3000 |

Slate | |

PTFE sheet, rod, rounds | 3000 |

Hard rubber | 3000 |

Plywood | 3000 |

Other woods | 3000 |