CROSSBAR REMOVAL

1.It is necessary to gain access to bottom side of cutter for crossbar removal. See Blocking Method page 19.

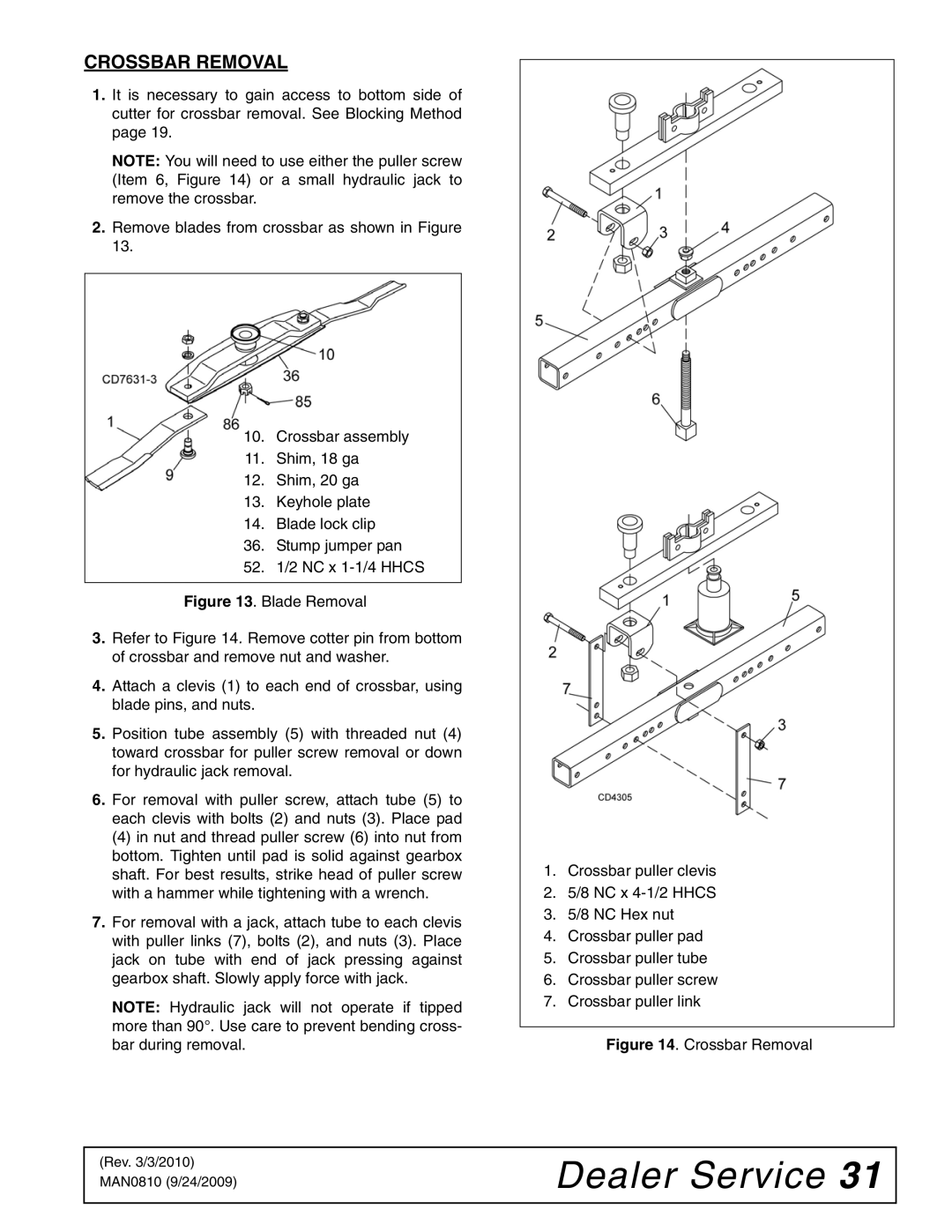

NOTE: You will need to use either the puller screw (Item 6, Figure 14) or a small hydraulic jack to remove the crossbar.

2.Remove blades from crossbar as shown in Figure 13.

10.Crossbar assembly

11.Shim, 18 ga

12.Shim, 20 ga

13.Keyhole plate

14.Blade lock clip

36.Stump jumper pan

52. 1/2 NC x

Figure 13. Blade Removal

3.Refer to Figure 14. Remove cotter pin from bottom of crossbar and remove nut and washer.

4.Attach a clevis (1) to each end of crossbar, using blade pins, and nuts.

5.Position tube assembly (5) with threaded nut (4) toward crossbar for puller screw removal or down for hydraulic jack removal.

6.For removal with puller screw, attach tube (5) to each clevis with bolts (2) and nuts (3). Place pad

(4)in nut and thread puller screw (6) into nut from bottom. Tighten until pad is solid against gearbox shaft. For best results, strike head of puller screw with a hammer while tightening with a wrench.

7.For removal with a jack, attach tube to each clevis with puller links (7), bolts (2), and nuts (3). Place jack on tube with end of jack pressing against gearbox shaft. Slowly apply force with jack.

NOTE: Hydraulic jack will not operate if tipped more than 90°. Use care to prevent bending cross- bar during removal.

1.Crossbar puller clevis

2.5/8 NC x 4-1/2 HHCS

3.5/8 NC Hex nut

4.Crossbar puller pad

5.Crossbar puller tube

6.Crossbar puller screw

7.Crossbar puller link

Figure 14. Crossbar Removal

(Rev. 3/3/2010) MAN0810 (9/24/2009)