SERVICE

The information in this section is written for operators who possess basic mechanical skills. If you need help, your dealer has trained service technicians available. For your protection, read and follow the safety informa- tion in this manual.

Before inspecting, servicing, storing, or chang- ing an accessory, shut off power source, make sure all moving parts have come to a complete stop, and disconnect PTO driveline.

LUBRICATION

1.Do not let excess grease collect on or around parts, particularly when operating in sandy areas.

2.Use a lithium grease of #2 consistency with a MOLY (molybdenum disulfide) additive for all locations unless otherwise noted.

NOTE: Be sure to clean fittings thoroughly before attaching grease gun. One good pump of most guns is sufficient when the lubrication schedule is followed.

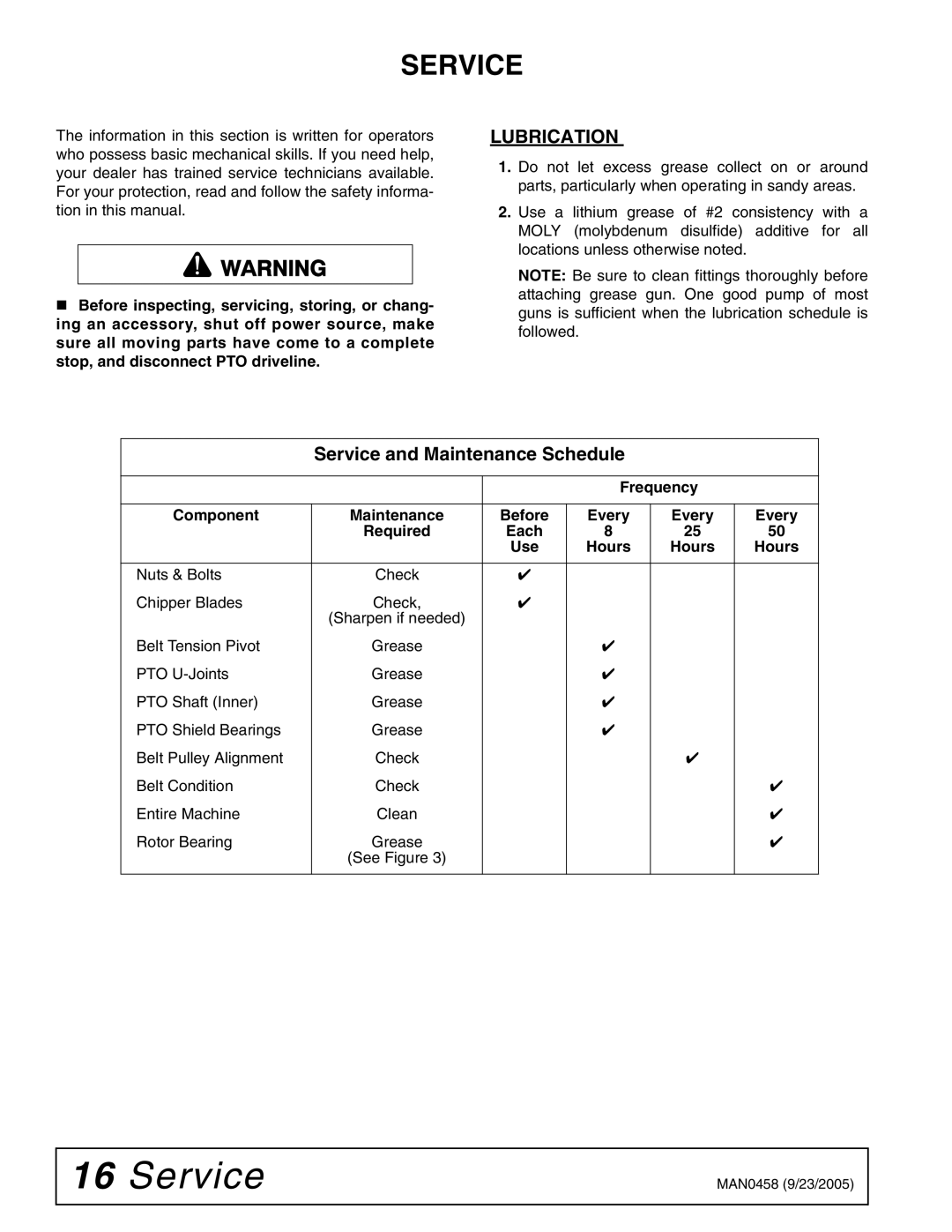

Service and Maintenance Schedule

|

|

| Frequency |

| |

|

|

|

|

|

|

Component | Maintenance | Before | Every | Every | Every |

| Required | Each | 8 | 25 | 50 |

|

| Use | Hours | Hours | Hours |

|

|

|

|

|

|

Nuts & Bolts | Check | ✔ |

|

|

|

Chipper Blades | Check, | ✔ |

|

|

|

| (Sharpen if needed) |

|

|

|

|

Belt Tension Pivot | Grease |

| ✔ |

|

|

PTO | Grease |

| ✔ |

|

|

PTO Shaft (Inner) | Grease |

| ✔ |

|

|

PTO Shield Bearings | Grease |

| ✔ |

|

|

Belt Pulley Alignment | Check |

|

| ✔ |

|

Belt Condition | Check |

|

|

| ✔ |

Entire Machine | Clean |

|

|

| ✔ |

Rotor Bearing | Grease |

|

|

| ✔ |

| (See Figure 3) |

|

|

|

|

|

|

|

|

|

|

16 Service | MAN0458 (9/23/2005) |

|

|