D2057A, D2058A, D2260A Mobile Base Instructions

Making a Base Plate

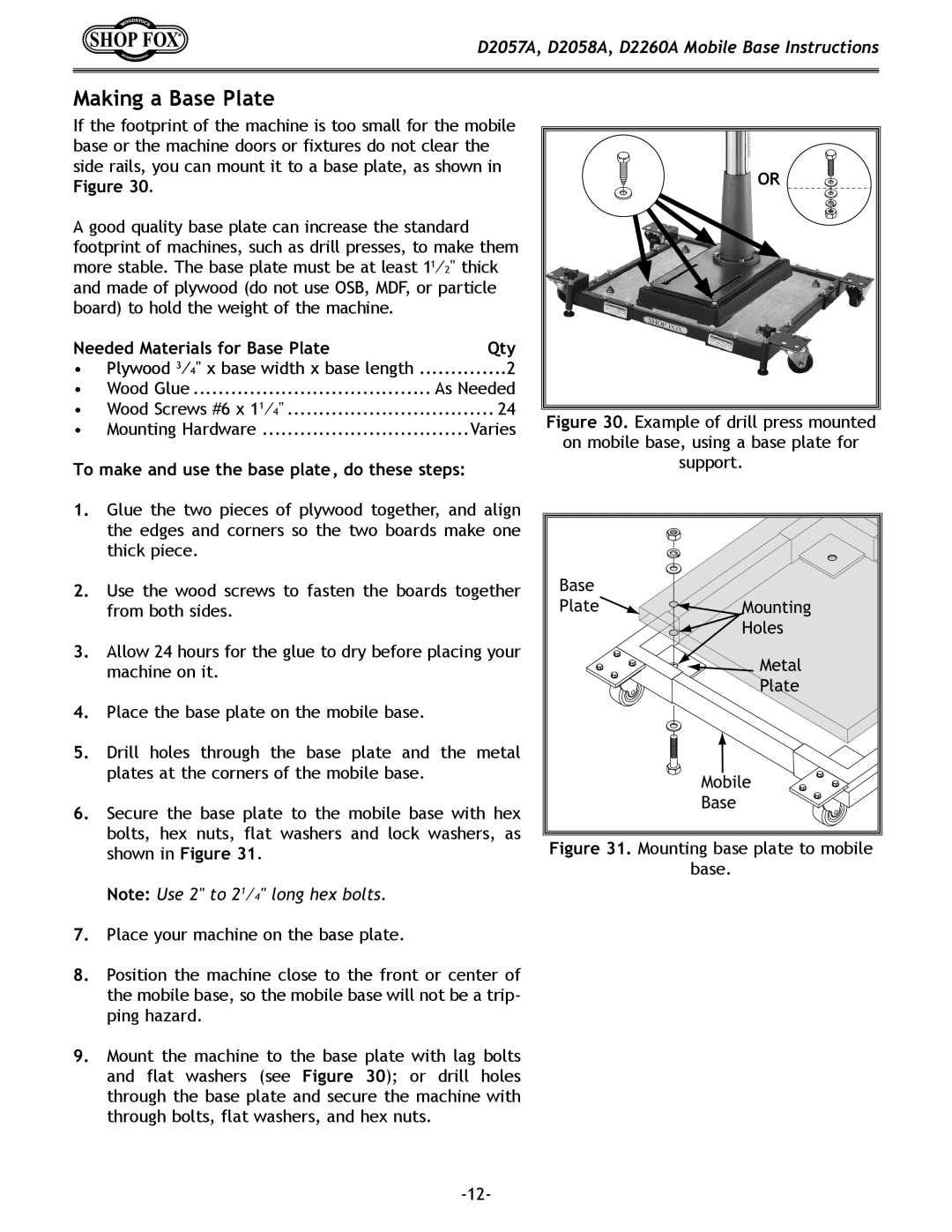

If the footprint of the machine is too small for the mobile base or the machine doors or fixtures do not clear the side rails, you can mount it to a base plate, as shown in Figure 30.

A good quality base plate can increase the standard footprint of machines, such as drill presses, to make them more stable. The base plate must be at least 11⁄2" thick and made of plywood (do not use OSB, MDF, or particle board) to hold the weight of the machine.

Needed Materials for Base Plate | Qty | |

• Plywood 3⁄4" x base width x base length | ...............2 | |

• | Wood Glue | As Needed |

• Wood Screws #6 x 11⁄4" | 24 | |

• | Mounting Hardware | Varies |

To make and use the base plate, do these steps:

1.Glue the two pieces of plywood together, and align the edges and corners so the two boards make one thick piece.

2.Use the wood screws to fasten the boards together from both sides.

3.Allow 24 hours for the glue to dry before placing your machine on it.

4.Place the base plate on the mobile base.

5.Drill holes through the base plate and the metal plates at the corners of the mobile base.

6.Secure the base plate to the mobile base with hex bolts, hex nuts, flat washers and lock washers, as shown in Figure 31.

Note: Use 2" to 21⁄4" long hex bolts.

7.Place your machine on the base plate.

8.Position the machine close to the front or center of the mobile base, so the mobile base will not be a trip- ping hazard.

9.Mount the machine to the base plate with lag bolts and flat washers (see Figure 30); or drill holes through the base plate and secure the machine with through bolts, flat washers, and hex nuts.

OR |

Figure 30. Example of drill press mounted

on mobile base, using a base plate for

support.

Base |

|

Plate | Mounting |

| Holes |

| Metal |

| Plate |

| Mobile |

| Base |