D2057A, D2058A, D2260A Mobile Base Instructions

7. Slide the other ends of the rails into the corner |

|

|

brackets from Step 6. Secure each end of the rails |

|

|

to the corner brackets with (2) |

|

|

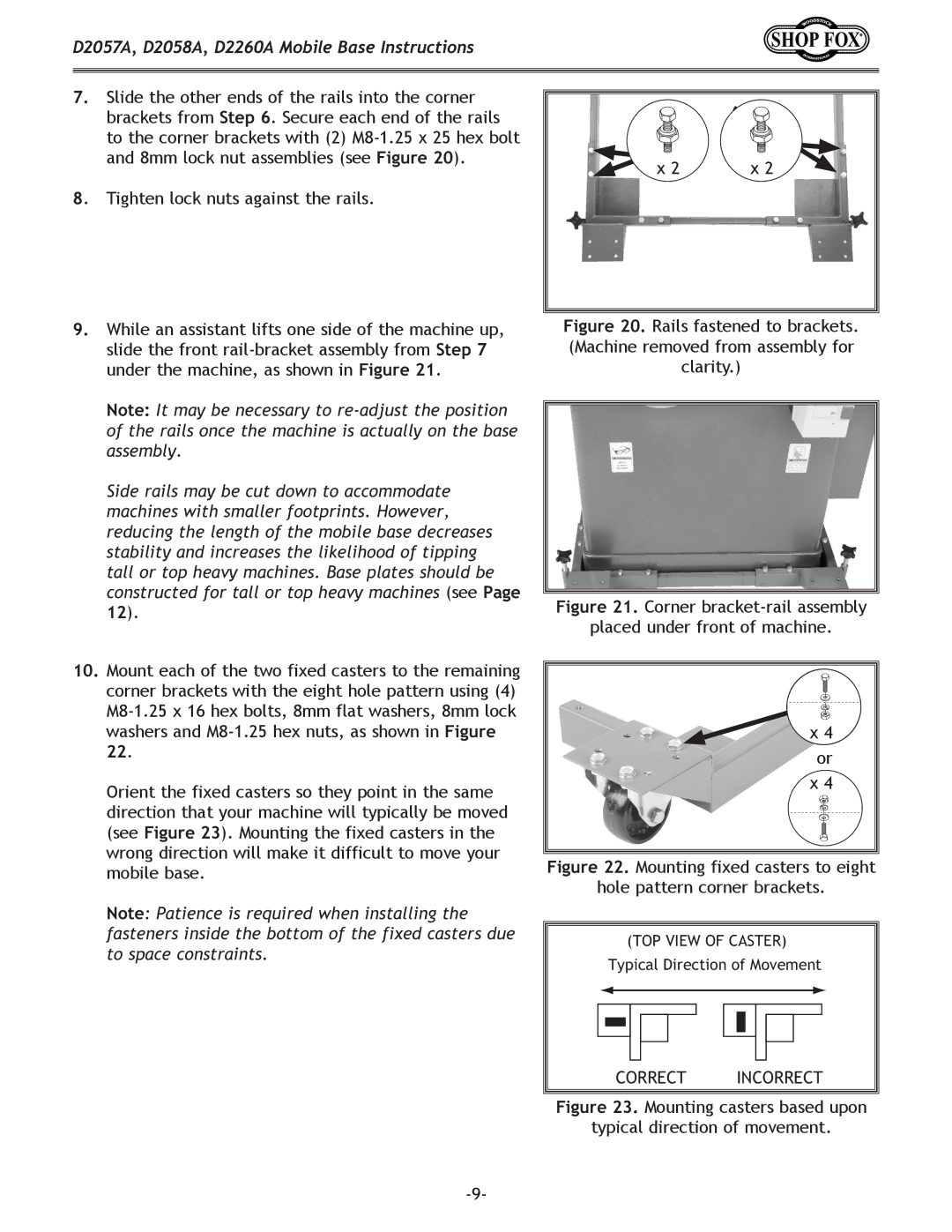

and 8mm lock nut assemblies (see Figure 20). | x 2 | x 2 |

|

8.

9.While an assistant lifts one side of the machine up, slide the front

Note: It may be necessary to

Side rails may be cut down to accommodate machines with smaller footprints. However, reducing the length of the mobile base decreases stability and increases the likelihood of tipping tall or top heavy machines. Base plates should be constructed for tall or top heavy machines (see Page 12).

Figure 20. Rails fastened to brackets. (Machine removed from assembly for clarity.)

Figure 21. Corner bracket-rail assembly

placed under front of machine.

10.Mount each of the two fixed casters to the remaining corner brackets with the eight hole pattern using (4) M8-1.25 x 16 hex bolts, 8mm flat washers, 8mm lock washers and M8-1.25 hex nuts, as shown in Figure 22.

Orient the fixed casters so they point in the same direction that your machine will typically be moved (see Figure 23). Mounting the fixed casters in the wrong direction will make it difficult to move your mobile base.

Note: Patience is required when installing the fasteners inside the bottom of the fixed casters due to space constraints.

x 4 |

or x 4

Figure 22. Mounting fixed casters to eight

hole pattern corner brackets.

(TOP VIEW OF CASTER)

Typical Direction of Movement

CORRECT INCORRECT